How to insulate the steam room in the bath Baths, saunas and pools

The steam room is the most important structural element of the bath. And in order for it to fulfill the most profitable duties as far safely, considerable attention is paid to its insulation. Insolation errors may entail rapid cooling and long heating of the room, a low concentration of steam, the appearance of mold, highlighting wooden walls and other troubles.

Content

Design layout

In order not to have the problem of how better to insulate the steam room , It is worth considering the location and layout of the bath, since compliance with simple rules will help to avoid unnecessary costs for the insulation of the room. So, the competent layout of the design implies the following:

- The size of the structure is determined on the basis of the planned number of people who will simultaneously be inside and the number of internal premises - the pre-tribbon, dressing room, the steam room, etc. As a rule, the area of \u200b\u200bthe pre-banker is 4-6 m 2, and the steam rooms are 6 m 2.

- Bath layout should be based on the accounting of possible heat loss and their minimization. Thus, it is advisable to provide closer to the entrance to the locker room, which can prevent the penetration into pair joints and cold air.

- Considering options, how to warm the steam room , it is advisable to carry out the inlet of the basin or the same pre-banner, which will be connected with a tambour with a steam.

- It is advisable to do the doorway not too wide, but necessarily with a high threshold.

- The optimal form for the steam room is a square, in the corner of which is the oven and preferably closer to the door.

Materials for thermal insulation

The modern market is saturated with all sorts of proposals that fill the range of insulation for bath buildings. The use of both artificial and natural seals is permissible as insulating materials for the wage.

TO natural raw materials Refers:

- pacle, which is used to insulate the slots;

- sFAGNUM, which performs the role of the interventory sealer;

- frame construction moss, serving for the insulation of the walls of the bath.

Such materials are environmentally friendly, do not emit toxic substances when heated, and also perfectly copble with the task - insulation of the room from heat loss. However, they quickly rot and are a good feed for insects, thanks to which natural insulation is recommended to process with antiseptics to insulate the steam room from the inside. In addition, the use of natural raw materials increases the length of construction work when erecting a bath.

As artificial materials The optimal option is extruded polystyrene foam or standard foam. These insulation are distinguished by a long service life, resistance to mechanical effects, moisture, insect. And their main advantage is a high thermal insulation coefficient.

General requirements for the seal for the steam room:

- The material must be fire-resistant, withstanding the temperature regime over 100 ° C.

- The insulation is also obliged to provide high insulation rates and are not subject to mechanical, biological, atmospheric influences.

Many materials are responsible for such requirements, but the most common today is basalt wool. It is famous for quality, functionality and relatively low cost. The best materials for the isolation of the pair compartment in the bath can also include synthetic plates: clay - for floors, and polystyrene layer for the roof of the bath.

Heat insulation parley with their own hands

During the construction of a Russian bathhouse at the railway site, an acquitted question arises: "Do I need to warm the steam room? ». Undoubtedly, the location and layout of the room itself play an important role, however, that the design has carried the minimum heat loss and maintenance costs, steam and waterproofing steam room should be provided. Consider more detailed each stage of the insulation of the pair compartment in the bath.

Ceiling insulation in steam

Any process of thermal insulation begins with the goal permission, how to insulate the ceiling in the steam . To do this, you will need to prepare twice as many materials, since the sealer layer must be greater. This phenomenon is explained by the fact that all couples and hot air rises to the ceiling. So, step-by-step insulation management looks like this:

- Cover the rolled paper rods in such a way that the junctions come in one on another brass with a generous stock.

- Secure the 5x5 cm wooden bars with wooden bars, between which the sealing material will be fixed.

- Using the monolithic foil and aluminum adhesive tape, take each segment of pastry to completely close all the joints, slots and gaps. This material will allow reliably to delay couples and condensate. Important! If you buy aluminum foil failed, it is permissible to use waxed paper or dense cardboard impregnated with olphos.

- Especially carefully fix the ribbon each joint to finally eliminate the possible way out of moisture on the ceiling.

- On top of the foil, secure small 2x3 cm bars in size to ensure the sufficient air exchange ceiling design.

- On the surface of the rail, you can mount the decorative finish to taste the owner.

Important! In the event of the construction of the frame bath, the ceiling thermal insulation is an indispensable process, and for the log structure, this insulation item can be missed. In a wooden log cabin on the ceiling, it suffices to attach thick boards - at least 6 cm, and a mineral wool layer at 15 cm.

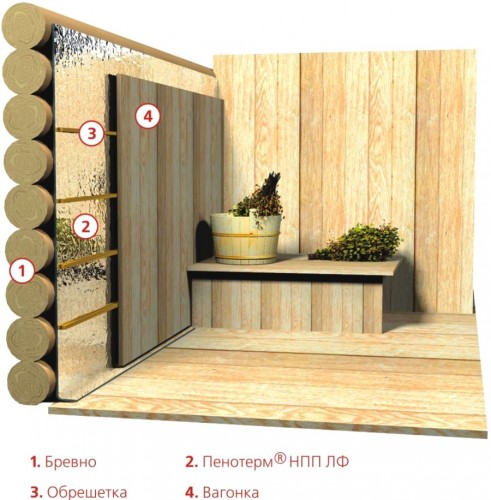

Wall insulation in the bath

Before insulation of the walls inside the parch premises, they should be prepared for the process. To do this, apply sealant or plaster into all available joints, gaps and cracks. As soon as the contents are completely dry, you can proceed to the thermal insulation of the bath.

The walls of the steam wages are insulated by a similar principle with the ceiling, where ventilation is assigned an important role. Consider a detailed step-by-step leadership of the insulation of the room.

- To fix the foil, initially attach to the wall of the walled wooden bars with a size of 40x40 mm. The desired direction is horizontally.

- Fill out the space between the slats by the sealing material of the same thickness - up to 40 mm.

- With the help of a construction stapler on top of the bars, it is necessary to secure foil, thoroughly pulling and eliminating the slightest clearances.

- Using a special aluminum tape, carefully insulating all the joints on the foil cladding.

- Then should be attached on top of the aluminum layer wooden bars, however, this time in a vertical position.

- These structural elements can be fixed facing material.

Important! Materials for decorative sheathing, as a rule, applies wood with a low density coefficient - pine, linden or aspen. And so that the heat loss is reduced to a minimum it is necessary to choose narrow slats, which are fixed in a horizontal order - this will reduce the risk of their deformation. Also do not forget about the processing of facing by a special composition, which is designed for rooms with high humidity and temperature.

Waterproofing floor in the steam

The next step in the insulation of the pair compartment in the bath is the floorproofing of the floor. Depending on the material from which the design is made - wood or concrete, there are several sealing options. Consider each of them more details.

Isolation of concrete floor

Method number 1. This is the easiest and most affordable option for waterproofing in a steam room, which is suitable for rooms where concrete flooded in a wedge compartment and the floor will be lined with tiles. The insulation process is as follows:

- It should be paramount to align the surface of the floor to the perfect state so that there are no slightest holes, bugro, cracks, etc.

- Then apply bitumen mastic and give the content to dry.

- On top of this layer, lay a runneroid or polyethylene film.

- Floor base is ready under the laying of ceramic tiles.

Method number 2. This method is somewhat more complicated in the implementation, however, the result of labor will be rewarded with high-quality floorproofing of the floor and eliminate the risk of damage to the materials. So, in order to insulate the concrete floor in the steam room, it is necessary to make the following actions:

- Fasten the plywood sheet on the draft floor.

- On top of plywood, it is necessary to put hydrosol - waterproofing material, the edges of which should be started onto the wall.

- By means of aluminum tape, carefully secure all the joints of the hydrosol layer and walls.

- All formed gaps need to be isolated using a construction dryer.

- After the slope of the slightest junction or slit remains on the surface, put the reinforced mesh and fill the concrete solution.

- When the concrete screed is completely dry, put the floor slab and proceed to the decorative facing.

Important! In order not to be wrapped with the cement wall, stick the tape on the lining, which acts beyond the floor. Also pay attention to the car's age for a bath - if you want to pour the floor in a wooden steam room, then the bath must have to breathe at least 2 years for a complete shrinkage design. Otherwise, the floor is deformed.

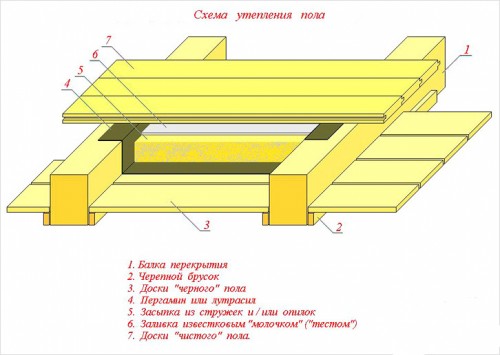

Wood floor insulation

Waterproofing of such a design is carried out by a similar principle with the previous method of insulation. Step-by-step leadership looks simple enough:

- Initially, the layer of a mineral and cotton mat should be fixed under lags at least 15 cm thick.

- Ruberoid or more modern modification - EuroBeroid is fixed on top of it.

- Treat wooden surface with antiseptic to eliminate the risk of rotting, eating materials insects, as well as self-burning.

- A draft floor should be used on top of the runneroid and stripping it.

- After that, you can proceed to the decorative cladding of the outdoor design.

So, the structure of the heat-insulated wooden floor in the steam room has the following form:

- foundational overlap;

- layer from the beam;

- vapor insulation layer;

- black floor overlapping;

- layer of lining and insulation;

- batten.

Recommendations for warming steam

In addition to the above methods of warming pair compartment in the bath, you must add some aspects regarding the process.

- It is worth remembering that the heat loss source in the bath is the windows. For this reason, it is recommended to put as smaller and tightly isolated structures. It is also desirable to mount the window as low as possible so that hot air inside the pair does not fall on it. And the main requirement is to install a two-chamber or three-chamber glass. The windows with single glass extremely negatively affect the efficiency of the steam room.

- The threshold and doors play an important role in the thermal insulation of the bath. As a rule, the low heat capacity of the paired room is explained by a large gap under the door through which hot air flows. You can easily eliminate this problem - install low door in the steam room.

- The furnace-heater is also a source of heat capacity. From what stones you put, it will depend on the speed of heating steam room and the time to hold heat inside the room.

Guidelines and rules as you can warm the steam room in the video are presented in a fragment: