Welding generator with your own hands Instruments,Useful advice

In order to perform welding work in the absence of electricity, a welding current generator is required. Such a factory production device can be purchased in the store, or make yourself. In order to make a decision, you need to get acquainted with the design of the generator.

Content

Device welding generator

The generator welding from the following main parts:

- diesel or gasoline engine (DVS);

- electric generator, the shaft of which is driven by the MOWER;

- rectifiers (for alternating current generators): necessary to convert an AC to a constant, which makes it possible to connect the welding machine of both alternating and DC;

- electrical and control unit.

Important: The welding generator (applying instructions obliges) can be operated near the fire shield equipped with fire fighting.

The principle of operation of the welding generator is as follows.

- Gases formed as a result of fuel combustion expand and lead in motion of the engine pistons. As a result of moving the pistons, the crankshaft rotates.

- The rotating moment of the crankshaft is transmitted to the generator rotor shaft.

- The resulting magnetic field generates (using inductance coil) electric current.

- Convertive devices are brought by current characteristics to the level necessary for welding.

How to choose a welding generator

Choosing between a diesel welding generators and gasoline, should take into account the main characteristics of the equipment.

Use diesel electric welding generator to operate without any additional equipment that converts the generated voltage, it is impossible. Diesel can be used for welding under certain conditions.

- If necessary, the simultaneous connection of several welding machines to a single point.

- If necessary, the fuel economy: important when welding the major part of the total operation.

- To ensure long-term and continuous operation of the welding machine.

Keep in mind that gasoline welding generators prices are lower, and during such equipment emits less noise. Furthermore, Petrol easier to transport due to less weight.

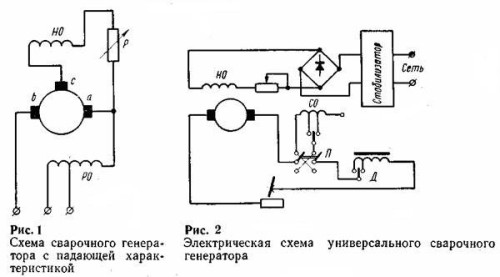

Welding generator: scheme of the device

welding generators schemes differ in their external characteristics. According to this principle, the device is divided into:

- generators universal;

- with drooping characteristic.

The last are the most popular and come in two types.

- With independent excitation. Power windings is provided by an external source of direct current. Demagnetizing winding is connected in series, and the current is regulated by a rheostat. By increasing the welding current during operation increases proportionally. Leaning external characteristic is generated decreasing the voltage at the terminals of the device.

- A self-excited generator: constant current to the field winding of the generator is supplied to the armature. Such devices often are used to work with stick electrodes. Stable current value is maintained voltage fluctuations.

More information about the self-excited oscillator circuit with can be found by viewing the video:

How to make a welding generator with their hands

In that case, if you own the basics of electrical engineering and want to save money, welding generator can construct themselves. To do this, buy some ready-made components and materials.

Homemade welding generator is assembled from the following components.

- Generator capacity of 5-10 kW.

- Gasoline internal combustion engine (e.g., trimmers).

- Rectifying device: it is a diode bridge, of the assembled high power diodes (depending on the maximum current). For mounting the rectifier bridge plate need of Micarta or fiberglass - the heat-resistant dielectric material.

- Regulator current: it is used as a rheostat smooth or stepwise action. The apparatus necessary to set the desired welding current.

Step by step instructions for the manufacture of welding generator with your own hands.

- Manufacture of metal corner frame size of 40 × 40 mm. For fastening of the internal combustion engine with a fuel tank, a generator and other structural elements envisage drilling holes places.

- Connecting parts of the frame by welding, we set the units and fasten them with screws and washers engravers.

- Pulleys fastened on the motor shaft and the generator, the distance between them is adjustable so that the transfer belt has been properly tensioned. To be able to adjust the future should be provided oblong holes for attaching the generator.

- Fasten and connect in accordance with the rectifier circuit and the regulator current.

- For the convenience of transportation welding generator is recommended to equip the wheels and folding handle.

Tip: The device can be made versatile - use it as an emergency power source. For what its circuitry should provide additional contact terminals.

Choosing a welding generator factory made: a review of the best models of the leading manufacturers

In order to select the welding generator in a specialty store, we recommend pre-acquainted with the technical specifications of the most famous models. Your attention - a description of some of them.

- Welding generator CAA: device secured in a metal housing with installed diesel internal combustion engine designed to work with different thicknesses electrodes (current up to 120 A). Furthermore, CAA can be used as a power source for power tools. SAK can transport the trailer to the tow hitch of any car.

- Welding generator Boar domestic production is produced in several versions (depending on the power, the volume of the fuel tank and configuration). Operating Current - 400 A. The unit can be used to provide emergency power. Imported motor provides quiet operation with a minimum amount of harmful emissions.

- Generator welding SDMO: aggregates given manufacturer are sources of single or three-phase current (depending on model), capacity - up to 6 kW. Weight generator in a metal tubular casing - 80 kg. For ease of transportation can be equipped with trolley kit.

- Welding generator ADD any modification is a powerful large-sized installation. ADD generators can be stationary or mounted on a truck chassis. Distinguish mono- and dvuhpostovaja units, cooling may be air or liquid. Running a diesel engine by using the starter and the battery.

- Welding EISEMANN generator provided with protection system against overloads. The gasoline company Honda engine in conjunction with a generator provides reliable operation of the unit. The duration of continuous operation - about 2 hours (depending on load). welding current is set three-position switch.

- Welding generator Honda: under this brand are available as power generators for industrial use, and compact, essential to work at their summer cottage. Weight EU10i model (capacity of 1000 VA) does not exceed 13 kg. Twice more powerful model EU20i weighs 21 kg. Reliability, low noise and vibration welding generator Honda did demand for construction work.

- Welding generator Denyo: most of the models are stationary units. The manufacturer equips the device of the fuel consumption and noise level control. Automatic protection is provided against leakage currents, reducing the oil pressure and battery discharge alarm. The engine will automatically shut down if the housing side door is not closed tightly.

- Welding generator MOSA: units of this manufacturer are available in different versions - from small portable to stationary. Portable models operate with electrodes 2-5 mm in diameter. Produced units with diesel and petrol engines. The high level of insulation and features circuitry allows Moz welding generator as the power source.

- Huter welding generator: Models of different power are presented on the market. DY6500LXW recommended for production needs: This unit is equipped with manual and electrical starters, as well as outlets at 12 and 220 V. The generator consumes 2.3 liters of fuel per hour and works continuously for 10 hours.

- Welding Skat Generator: Models are characterized by assembly quality. In addition to ordinary, the manufacturer has mastered the release of inverter units, providing high quality welding current. All SKAT models are equipped with a built-in AVR block, thanks to which the current parameters are aligned.

With some models, I will familiarize the following video.

The information set forth in the article will help determine the choice of a welding generator or with its independent manufacture.