Walls made of ceramic concrete blocks Walls

For more than 60 years in the building materials market, a ceramzite concrete is used. Well-known panel houses ("Khrushchevki") were built precisely from it. During the long years of operation, ceramzite concrete blocks have proven itself as high-strength and convenient material for construction.

Content

In terms of its composition, the ceramzite concrete is a lightweight concrete with the addition of clamzite as the main filler, as well as cement (or other binder filler - lime, gypsum, etc.) and sand. Ceramzite is environmentally friendly, as it is actually foamed and baked clay. The solid appearance of the granule was determined by its mechanical strength and resistance to external influences. Ceramzitobeton, due to the presence in the composition of clay, is characterized by high strength, as well as ease. Ceramzit concrete blocks are obtained by vibratingressing and subsequent thermal processing on special equipment. Currently, this wall material is widely used in low-rise construction. Outdoor walls are erected from it, as well as interior partitions for residential buildings, country houses, garages, hangars, warehouses.

Benefits of walls from this material

Walls made of ceramic concrete blocks are distinguished by a number of benefits:

- high strength and frost resistance;

- ecology;

- resistance to rotting, mold, rust;

- refractory, as well as moisture resistance;

- low cement consumption compared to brick masonry;

- ease (unlikely shrinkage of the building and the appearance of cracks), as well as the lack of need for a massive foundation;

- a small specific gravity (less than 2.5 times than brick walls) and convenient volumetric parameters that allow you to build walls from the ceramzite concrete into a fairly short time - three times faster than bricks;

- high heat and sound insulation properties.

The voids in the blocks form a kind of frame, which increases the bearing ability of the walls. It should be borne in mind that in dense ceramzite-concrete blocks, sound insulation indicators are lower compared to the blocks of a smaller density. In addition, the more easier the blocks of the ceramzite concrete, the more porous - therefore, thermal conductivity increases, as well as vapor and moisture permeability. In vapor permeability, the ceramzitobetone is somewhat inferior to other materials - therefore the use of thermal insulation materials that do not transmit steam, in buildings from the ceramzite concrete is not recommended. Or it is necessary to provide for the residential premises a vapor barrier membrane, as well as the supply and exhaust ventilation.

Using insulation

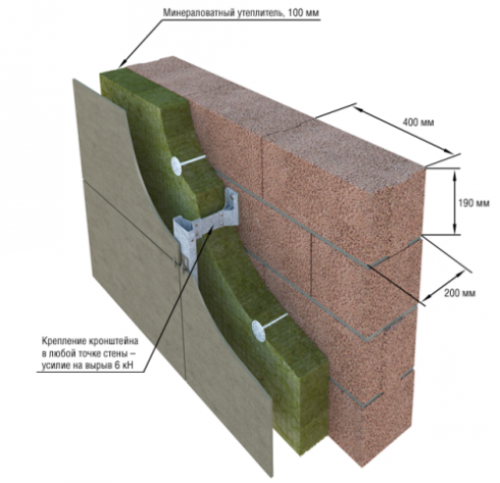

It should be noted that if the construction of ceramzite-concrete blocks is intended for permanent residence, then the insulation must be used. With the outer insulation of the bearing walls of ceramzite-concrete blocks, mineral wool is used, as well as foam (it will cost a little cheaper).

Insulation are attached to a stripped base with a special glue. Polyfoam must be fixed with dowels, the seams are filled with mounting foam. Mineral wool requires reinforcing walls to harden the design.

There are also many options for the inner laying of thermal insulation - for example, foam, foaming. This method of insulation (the so-called three-layer walls) significantly increases hydro and thermal insulation.

Calculation of walls of ceramzite concrete blocks

The thickness of the walls is determined depending on the designation of the structure. According to the construction standards and rules (SNiP), the recommended thickness of the wall house of the residential house of ceramzite concrete blocks is not less than 0.64 m (with mandatory insulation). Some experts argue that the thickness of one block is sufficient for a residential building - 390 mm, while for country summer houses, hozpostroops, the inner walls are sufficiently thickness of the walls in a half-block.

The calculation of the number of building materials of the walls of ceramzite concrete blocks is produced, based on the total length of the walls (including partitions), as well as the height of the ceilings of the floor (the length is multiplied by height). At the same time, do not forget to consider the estimated thickness of cement seams and a screed solution (15 cm). The resulting number is multiplied by the thickness of the walls, divided into the volume of the unit - as a result, the required number of clay-concrete blocks is obtained.

If you multiply the number of blocks on the cost of a unit of material, you can calculate the estimated value of the ceramzitone wall. If necessary, take into account the cost of purchasing thermal insulation materials.

Erecting walls of ceramzite concrete blocks

The design of the walls of ceramzite-concrete blocks is largely similar to brickwork, at the same time there are some features.

For masonry of walls from ceramzite-concrete blocks, the following tools and materials will be needed:

- wooden hammer;

- construction level and plumb;

- armature or reinforced grid (if reinforcement is envisaged);

- cement capacity, as well as shovel;

- roulette or measuring tape;

- rubber hammer;

- construction parliament;

- bulgarian with a circular diameter of 230 mm;

- wooden rail order for laying masonry, as well as a cord-moor;

- fishing.

Initially, you need to prepare a solution and ride it to the placement location. You can independently prepare a solution of sand and cement mixture (1: 3 - 1: 4, depending on the cement brand). You can also use glue cement - it is much easier than the cement-sand screed.

The choice of masonry method depends on the required wall thickness, the method of laying the heat-insulating material and the planned wall decoration.

To ensure the reliability and strength of walls of ceramzite-concrete blocks, you need to follow certain rules:

- Stacking ceramzite concrete blocks are carried out on the strengthened foundation, which stood and already gave shrinkage. Initially, the foundation is carefully insulating. To do this, the roller roofing robe in two layers is placed on a cement screed layer.

- The blocking of blocks start with the corner of the construction and move around the perimeter with rows. It should be noted that carriers and inner walls, as well as partitions, need to be erected simultaneously.

- Each row must be sequentially completed around the perimeter. At the same time, it is necessary to track the height of the masonry so that the beginning and end of the row coincided. For alignment in height, they are stretched along the level of a fishing line or thread - at a distance from the foundation, which is equal to the height of the block, taking into account the cement screed layer. For greater alignment accuracy, you can use the laser level.

- To connect the series between the walls, thermal insulation material is used (for example, foam). Other blocks are connected using a solution. After applying to the blocks of the solution - it is not trusted for alignment, it is not a trowel, but a new block. Vertical block seams do not need to be filled with a solution, thanks to the system of ridges and grooves there will not arise through the slots. The thickness of the seams between horizontal rows should not exceed 10 cm. For high-quality laying, it is necessary to withstand the same thickness of the seams between blocks.

- It is recommended to strengthen the reinforcement or reinforcement grid of the seams around the perimeter - every several rows.

- The outer side of the walls erected from ceramzite-concrete blocks needs to be protected against atmospheric influences, therefore, it will be necessary to be plastering or the use of facing materials.