Make a glass of glass with your own hands Interior items

Glass tables look appropriate in any interior. Their elegant and air appearance does not overload space, visually leaving the room spacious and unlocked. From such a material like glass, you can make a serving, magazine, computer or even a dining table, and make the design is quite possible with your own hands.

Content

Types of glass tables

Such interior items differ in form, design and execution materials. As for the geometry of the table top, the glass of glass happens:

- round;

- rectangular;

- triangular;

- square;

- oval;

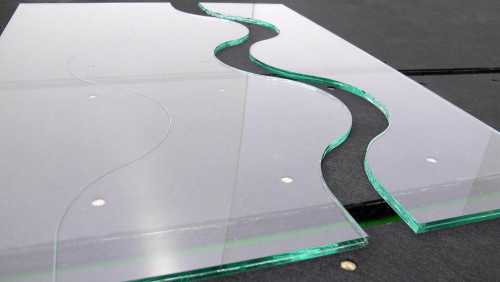

- have an unusual curly shape.

Depending on constructive features, distinguish such types of tables:

- transformer;

- table with lower shelf;

- sliding table;

- mobile design;

- monolithic table and others.

Such furniture can also be manufactured from various types of glass. For example, the coffee table is made of black, hardened, tinted, matte, transparent glass, or from a triplex.

A variety of execution is distinguished not only by table tops, but also a prestole and legs of structures. The most common option is the materials like wood or chrome metal. Very richly and sophisticated forged tables with glass, which are chosen for interiors in a classic style. Rattan's table with glass looks simpler, but fits well into most of the designs.

Pros and Cons Glass Designs

The positive qualities of glass tables include such:

- beauty, accuracy, ease of appearance;

- the ability to enter a similar element of furniture in almost any design;

- ease of care, hygienicity, environmental friendliness;

- sufficient strength;

- resistance to chemical media, moisture and temperature conditions of the environment.

Among the minuses of glass tables should be called the following features:

- on the glass often there are divorces from water or incorrectly selected care products;

- poor-quality or cheap material quickly scratches;

- on the glass often remain traces from fingers;

- with neakkurat handling, you can get fractures and chips, and even smash the table at all;

- finished designs are not cheap.

Make a glass of glass with your own hands

Preparatory stage

Having decided to make a glass table itself, you probably decided in advance with its location and role. Depending on where this subject of the interior will be placed and what function it will perform, the pre-sketch should be done on paper, taking into account the characteristics of the room in which you put the table. On the sketch you need to specify the table top and the placement of the legs.

To make a glass table, prepare such materials and tools:

- glass thickness from 6 to 12 mm;

- special glue for glass;

- cleaning agent;

- acetone;

- fire or emery bar;

- legs for design;

- suction cups for legs;

- sunflower oil;

- phaneur or chipboard, on which you will cut the glass;

- paste for polishing material;

- marker or marker;

- line and roulette;

- glass cutter;

- rubber head hammer;

- rag;

- protective glasses and gloves;

- bulgarian with grinding circle.

In this paper, only clean and dry glass should be used, on which there is no dust and other, even the smallest, pollution. You can clean the material with a simple solution of food soda using a soft rag. If the glass remains dirty, it can get off the noise line.

Cutting the glass is more conveniently on a large sheet of plywood or chipboard, and the material should come into contact with the table with almost no gaps and pressed as close as possible.

Coffee table made of glass and metal, photo:

Features cutting glass

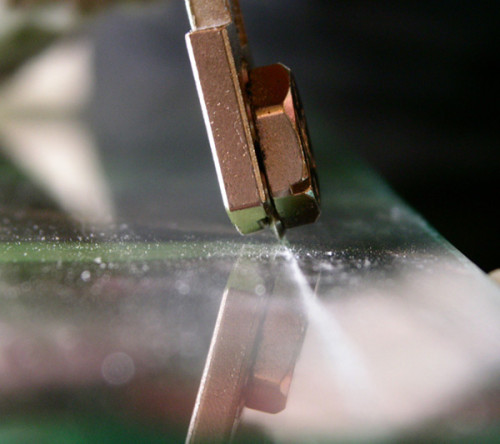

The glass is more convenient to cut the glass on a thin and long metal line, and you can draw the line in advance to the felt-tip pen, so that it is later a glass cutter on it. If you are a novice in a similar matter, it is better to practice on an unnecessary piece of glass, and then proceed to creating a table.

Note that the line that you will be cut the glass cutter is desirable to perform at once, and so that the tool worked easier and better slid, it is necessary to lubricate it with vegetable oil. When working with diamond glass cutter, a very thin and almost imperceptible line remains on the material. Putting the glass to the edge of the table so that this line coincides with it, the material broke through the end of the outbreak. Pressing force should be approximately 2 kg. Breaking the glass must be in protective gloves, so as not to cut your hands, and your eyes must be protected with glasses.

After you break the bulk of the glass, sharp protrusions or extra pieces can remain on the cut. You can remove them with pliers, put on special rubber lining. If there are no such lines, use paper folded in several layers.

The glass cutting is made from the far edge, making a fairly strong pressure on the glass cutter. If you work as a sharp tool, but no inclination does not work, lubricate the kerosene disk and spend the same line several times. If you are not sure that the incision turned out the desired depth, turn the glass to the back side and do the procedure again.

If you make a round coffee table with glass or work with any other complex curvilinear forms, for convenience the easiest way to use the stencil. Cutting the circle according to the stencil, swipe from it with a glass cutter rays and shake the glass in parts.

Reinforced glass cut in a special way. Initially, the smooth side is carried out with glass cutter, and then with the help of a sharp tool, a deep lust up to the grid is sprinkled. After that, the glass is turned over to the opposite side and bleed along the end line. The grid is snacking or cut off.

Table top processing

After cutting along the rim on the glass, sharp protrusions that should be removed are often left. At the production of ends treatment on special machines, under the domestic conditions for a similar purpose, you can use fir-handed tools. Please note that for such work you will also need to protect your hands with dense cotton gloves or mittens.

Clean the sections of the sections can be a file or emery bars. A file in the process of performing manipulations should be periodically wetted in a turpite or in kerosene. When working with thin glass you need to be very neat.

The next step is polished the ends, for which the grinder with grinding circle is used. The speed of the grinder should be small and reach 1200-1700 revolutions per minute, so that the glass has not overheated. The first occasion should be used coarse paper, then change it into a smaller one, and the final stage can be pulled out the ends of the fine-grained paper. In the process of operation, glass can be wedged with water. You can achieve a special smoothness using a felt circle or a special paste for polishing the glass.

To make a tabletop more attractive and unusual, there are several ways to decorate the glass. Methods are very often used:

- decoupage;

- etching glass;

- applying sandblasting pattern;

- toning;

- printing images;

- stained glass drawing;

- use double glasses with decorative layers of flowers, stones, seashells, coffee beans and other elements.

Decoupage and stained-in painting are made from the "inside" table tops, so that the drawing is not damaged during operation. In addition to the above methods, the glass table can be decorated with decorative illumination, which looks very effectively, especially in the dark.

Fixation of legs

Before mounting the legs in each of them, it is necessary to make a hole from the end side. These holes are needed in order to fix special suction cups in them. For greater strength, the sucker is planting on glue.

While the glue dries, the marker is placed on the tabletop, where the legs will be mounted. In these zones, it is necessary to degrease the surface with acetone or gasoline.

As for glue, in the manufacture of a glass table, use the composition used for mirrors is not recommended, since it dries long and shines through the transparent surface. For a glass table, it is better to purchase special high-quality glue. In the Russian market you can find 2 popular varieties of such materials: the compositions "Glass-glass" and "glass-metal". For the polymerization of such adhesion, it is necessary to affect the ultraviolet lamp.

The legs are glued to the table one. Initially, the element is lubricated, placed it to a predetermined place, they are waiting for about 30-60 seconds, after which they direct the ultraviolet lamp to this section and leave so far to the total polymerization of the composition.

Since after the final frosting of the glue to dismantle the legs will not be possible, their locations should be noted very carefully.

Useful recommendations

The coffee table from glass requires special operating conditions. First of all, we note that you need to handle it carefully, trying not to smash the countertop. Caring for such a table does not represent anything complicated, glass needs from time to time to simply wipe the microfiber with a soft, using a tool for washing windows.

On the glass table, scratches sometimes appear. Fix the similar defect will help a special paste of Goe. It is fillaped to the state of very shallow crumbs, they are applied to a piece of cotton wool, wand or tampon, after which the damaged surface is polished. Do not do strong push. Scratch is processed within 15 seconds, then the paste is erased and repeat the procedure again. In some cases, the number of approaches can be large.

There are other ways to eliminate or disguise scratches on the glass. You can purchase a "polar" or its analogue in the store, you can use a simple toothpaste, although its efficiency is much lower. You can disguise damage and with the help of an ordinary transparent nail polish.

To prevent the appearance of scratches, the glass table is better putting napkins or small bamboo mats.

Coffee tables from glass, photo: