Stampering machine: characteristics, design and manufacture with your own hands Instruments

The use of a clinker tool to highly provides accuracy and impeccable quality of cutting any non-metallic material. With it, on a given form and dimensions, marble, porcelain stoneware, tile, large-sized plate of large thickness and other durable materials are easily processed. In addition, when using a saw with a diamond edge, the stone machine is perfectly suitable for working with wood.

Content

Main characteristics and classification of machines

The main feature of this design is wetting the water cutting surface of the machine. Therefore, the electric pump must be the mandatory component in the process of diamond cutting. Water increases the life of the disk, cools it during operation, and also reduces the noise and distribution of construction abrasive dust.

The range of applying the machine for cutting the stone is very wide: it is cut with stair steps, a building stone, a brick for laying walls concrete pipes and so on. It is successfully used both in the conditions of dacha construction and the interior decoration of premises, as well as when preparing for masonry of refractory bricks.

With this tool, cutting can be made not only at right angles, but also under the tilt of 45 degrees.

Depending on the manufacturer and model, the machines are:

- stationary or manual;

- single head or two-headed;

- with a mechanical or pneumatic clamp;

- with or without cooling system;

- with lower or top drive;

- with a different way of feeding the plate: bottom, pendulum or front;

- they differ in the diameter of the disk, power, length and depth of cutting.

From here and different their purpose:

- Cutting machines are used to cut the stone slabs of all kinds of configuration.

- Calibrational installations are used for rough work on alignment of the stone slab.

- Electrical machines have a small weight and are intended for significant workshops.

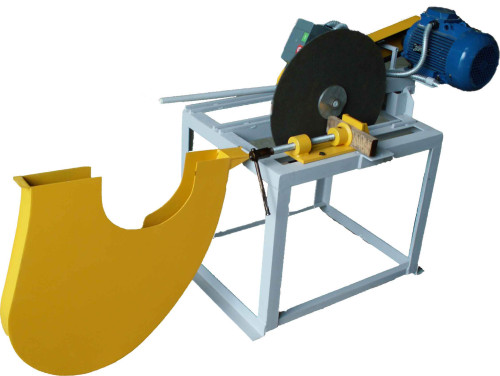

- Models in which the drive is located on top are called rail and the submersible pump is used. The advantage of such a design is the possibility of high accuracy and quality seam.

- The clinical machine, which drive is located below, is suitable for cutting the plates of any area, it is usually small and is often used in the room. The main consuming material for all machines are diamond discs whose cost is quite high.

- The most popular machines include tiles. Depending on the upcoming volume of work, they are hand and electric. Manual apply where there are not many works, and the thickness of the tile does not exceed 15 mm. For example, with a length of 400 mm, the machine perfectly copes with a thickness of up to 8 mm. The longer the handle at the tool, the more thick tile he can cut.

It is worth noting that many models have a swivel line and allow cut at an angle.

The cutting process occurs as follows: the tile is reliably fixed in the clips, after which the label is applied to the abrasive wheel. Then a strong pressure tile breaks along the line.

Electric tiles are used when the working volume is large, for example, during the facade of the building. Such equipment provides the most flat cut line without chips and scars. Well suitable for cutting the tile and tiles on a solid and soft basis.

Constructive machine

Modern models achieve such accuracy of cutting parts that the joints are practically not noticeable. Due to this, they found their widespread use in all sorts of creative workshops on the manufacture of decorative elements of the interior and landscape.

The design of a typical machine must include:

- frame;

- engine;

- transmission;

- cut;

- auxiliary equipment (for example, pump).

Most often, the frame is made of cast iron or high strength steel, as it serves as a frame for fastening the rest of the nodes.

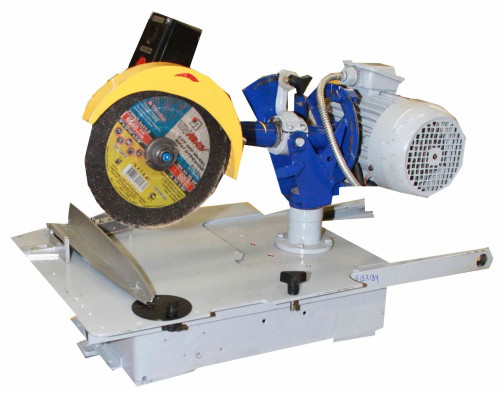

Electric motors that equip the machines are needed to carry out the drive to the cutting tool. They are different in power and are mostly calculated on 220V and 380V. Of course, high consumption provides greater power and allow the use of larger diameter discs. If the model is with the upper drive, the engine is attached to the top of the design on a special rail and is a moving element. If the lower drive, the engine is cling directly to the frame. In the first case, the stone is served to the bed, in the second - the cutting tool itself is moved to the stone.

Stamper machines are equipped with several types of transmissions: belt, chain, gear, with direct drive from the engine, etc. The type of gear is selected depending on the potential of the engine and from those functions that are laid in this model.

The water cooling system often has a closed cycle, that is, in the process of operation, the abrasive of the diamond disk and dust from the cutting fall into water, repeatedly circulates in the system. As a result, such cooling negatively affects the quality of cutting due to the presence of unnecessary particles, and also reduces the service life of the disk. Therefore, water cooling system needs a frequent replacement of water. Many professionals refuse to use standard cooling, and instead simply continuously serve clean water into a cut slicer, which, spent, enters the pallet.

Some manufacturers equip their models with engine cooling fans, which has a positive effect on the execution of large volumes of work.

Advanced machines are equipped with a security system and overheating protection. This means that if the engine work was discontinued due to turning off the electricity, then when it is repeated, it will not start independently.

Expendable materials

Diamond discs correspond to the sawing process, which, depending on the diameter, can penetrate into a depth of 420 mm. To work with each material, a specially designed disk is selected. They are: on concrete, travertines, granite, mramor, glass, tile, sandstone, as well as universal. Disks with continuous diamond cutting spraying give a neat smooth incision for the mramor, ceramic tiles or finishing brick.

As for segment disks, they have a much longer service life, but they are suitable only for coarse works, where the presence of small chips or irregularities of cuts is noncritical.

Working with diamond disks is undoubtedly more costly compared to using conventional segmental analogs or turbo-type disks (with grooves). Therefore, when choosing, it is necessary to be guided by the ratio of prices and the desired result, performance and quality.

How to choose a machine

The Russian market presents cutting machines both domestic and imported. The average price for professional clinker equipment - 80 000 r.

- First of all, it is worth finding out whether this machine model has a narrow specialization or it is universal - some samples are made specifically to perform some kind of task.

- One of the main parameters when choosing a clinker, before buying, it is the depth of its cut. Pay attention also to the length of the cut and the maximum possible diameter of the cutting disk.

- Ask, which maximum permissible load can withstand this equipment.

- Find out how high quality and exactly the incision is performed, which angles can be set up the machine.

- Specify whether it is possible to change the depth of the cut during the work during the work, and also remember that the saw disk must necessarily have a protective housing.

- It is important to know how much water is fitted in the container for cooling the disc.

- The working surface of the fugoval table should be perfectly smooth, smooth, and the support is stable and not staggering.

Stamper Machines Fubag

Productive work is based on two components: the first is a high-quality machine, the second is the right choice of a diamond disk.

Products of the German company FUBAG are designed to cut all types of artificial and natural stone, ceramic tiles, as well as other building materials. All stammerable equipment of the brand fully complies with international standards of quality and safety, and also features impeccable assembly and high accuracy of the recent.

Advantages of Fubag machines:

- wide range. The ability to select the machine depending on the type of work performed and the disk selection in accordance with the material being processed and the amount of load;

- easy operation. Functional features and design of the equipment are designed in such a way as to make work with a clinker machine as comfortable and understandable as possible, and its price is optimal;

- thanks to the tireless operation of engineers, the quality of assembly and reliability of FUBAG tools is constantly growing, improving their operational qualities.

Stamper Machines Diam.

Equipment for the production of South Korea has proven itself in the construction market, thanks to the optimal price / quality ratio. DIAM not only supplies durable and reliable stone machines, but also all sorts of components: cutting circles with housings and without, diamond discs, means for processing stone and so on.

The company's assortment is present both bridge and small-sized console machines for granite workshops, universal machines, cutters of seams for landscape and construction work.

Stamper machine with their own hands

By its design, this tool is a fairly simple mechanism and is not much different from the ordinary circular saw on a tree, and therefore it is quite possible to collect at home.

The main nodes that the machine must have:

- Steel shaft to which the disk is attached.

- Belt and pulley connecting the shaft with a motor.

- Caliper or platform on which the material for cutting is located.

- Protective casing.

- Steel tank for coolant.

Considering that the stone is much hard than the tree, to set the cutting wheel, the shaft must be sufficiently rigid. For a small disk with a diameter of up to 100 mm, the shaft can be 12 mm, and for a disk in 400 mm, the shaft diameter should be at least 20 mm. To ensure the rigidity of rotation, the disk on both sides is fixed with flanges, and the less the disk, the greater the flange should be. This ensures the accuracy of the cut.

The saw shaft is necessarily supplied with ball bearings that provide accurate and easy rotation. This extends the life of the cutting disk and provides a smooth cut.

As a drive, you can adapt, for example, an electric motor from a washing machine, the main thing - so that it can develop the speed of 1500 revolutions per minute and had a power of 180-250 W. In such a case, the friction wheel may be two-stage and have a gear ratio of 1: 1 or 1: 0.35.

A wedge belt is suitable as a transfer, for example, from Zaporozhets.

The main element in the machine is the spindle - the place where the disk is mounted. Detail is fastened to the side of the tank wall with bolts.

The clinker machine must be necessarily equipped with a cooling system, or simply a bathroom with a liquid, through which, rotating, passes the saw. The heat that occurs during sawing, as well as abrasive and dust, should be discharged. In addition, the wetting of the surface reduces the force of friction, creating the effect of lubrication.

For cooling, it is possible to use light oil, which is used in the workshops of the car repair, or mix kerosene with engine oil in proportion 10: 1 (2).

The use of water-oil emulsions is also possible, but they can lead to corrosion of the elements of the machine.

The automotive antifreeze is good - he is not angry, slowly evaporates and does not have a strong smell.

In the pallet with oil, a lot of waste, dust and abrasives are formed, which must be removed periodically. In order for dust completely donkey and it was possible to remove it, must pass for several days. The liquid above the sludge is carefully drained, and if necessary, use again. Its level in the pallet should be such that the disk is immersed to the depth of no more than 12 cm.

In many homemade machines, the pallet is a tank that carries a constructive function, being the basis for the caliper and spindle. In this case, it is made of durable steel sheets, hermetically brewing walls. In other cases, the tank is made from fine metal and mounted in a wooden frame, which serves as the base of the machine.

Vibration and noise can be reduced by laying under the bottom of felt or rubber gasket.

Safety regulations

We must not forget about safety techniques when working with a clinker machine:

- Take care of a steady horizontal tool position.

- Be sure to wear workwear, protect organs of vision, hearing and respiratory tract.

- Do not use the equipment if there are no parts on it: the protective casing, grounding, the insulation of the wires is broken.

- Use good quality diamond discs and only in accordance with the selected material.