Rolled roofing do it yourself Construction

A few years ago, if necessary, to use rolled roofing material, the only referenced was the main available. Its characteristics were not very high, and the service life was usually not exceeded 5-7 years. With the development of technologies, naturally, new developments appeared in the direction of soft coatings for the design of the roof, which in many cases are a very profitable solution.

Content

- Composition of rolled roofing

- Types of rolling roofing

- Roll Materials for Roofing

- Roofing of rolled materials

- Proper laying of the rolled roof

- Methods of fastening

- Mastech preparation methods

- Roll roofing: Intrusting Mounting Technology

- Laying rolled roofing with a cold way - distinction

- Arrangement of complex places - Promotions to vertical surfaces

- Conclusion

Composition of rolled roofing

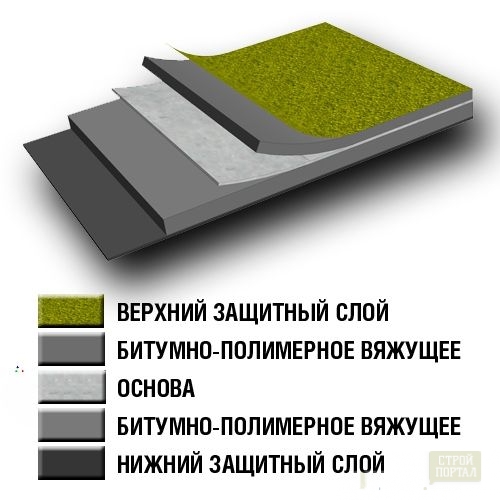

Rolled roofing materials of unequal. They are classified, based on the characteristic features of each component of the canvas:

- bases that ensure strength;

- binder solution affecting the density and integrity of the structure;

- surface sprinkle of varying degrees of graininess, which performs protection from the effects of all natural phenomena - moisture, ultraviolet, mechanical load.

Important! More accurately imagine the features of the structure of this category of materials, if you can view the photo of the rolled roof.

Based on the structure of the canvases take:

- fiberglass;

- glassball;

- polyester

Important! The most durable and expensive is considered to cover the last type.

As a binder, the bitumen of the following species is used:

- oxidized;

- polymerized.

Important! The material of the last type is an improved, a higher-tech option, which is characterized by high resistance to breaks, due to excellent elasticity and temperature drops.

Surface pads happens:

- scaly;

- dusty.

Important! For all types of material, regardless of the quality characteristics, the norm of the rolled roof is considered the norm from 0 and up to 30 degrees.

Types of rolling roofing

Select 2 types:

- Basic. Production is carried out by processing glass cholester or cardboard astringent substances.

Important! This material is also divided into coating and restless and can be bitumen, bitumen and degrees.

- Domestic. Made by treating a binding mixture at appropriate temperature mode with the addition of various fillers. The resulting composition is rolled into the canvas, applying the special equipment for this purpose.

Roll Materials for Roofing

Current manufacturers offer a fairly wide line of rolled roofing materials, which can be determined to determine the following categories:

- Ruberoid based on cardboard (pergamine). Send demand among consumers due to low cost. Lifetime is small - about 5 years. The minimum number of layers applied is three. An improved modification of this species is a ruble, the installation of which takes less time.

- Gymelockeroid. Polyers or glass gamble are used as the basis. The glasskerberoid is considered to be a modern version of the roof with a high level of reliability. The service life reaches 15 years, which ensures the relevant revenue of the base.

- EuroRuberoid. This focusing material is quite popular among consumers of our country. This coating is not terrible temperature sharp differences and frosty weather. The integrity of the canvas can be maintained for 30 years. Standard number of layers - 3.

- Membrane coating. The most modern type of roof, distinguished by durability and speed of installation. One of the varieties is self-adhesive canvas. The cost of such a coating is much higher, but the use of mastic and nails is excluded. The effects of the heat of the Sun makes the material of the adhesive - when performing installation work into suitable day, the membrane itself is reliably connected with the base.

Important! Regardless of the type of material selected, it will not be difficult to make it styling with your own hands, even in the absence of great knowledge and skills in the field of construction.

Choosing a suitable type of roofing rolled material, at all, take a look at the marking indicating the characteristics:

- roofing (k) - suitable for the design of the upper layer;

- lining (P) - serves as a lining under the top layer;

- elastic (E) - applied when arranging vertical complex sections.

Important! Material with a certain marking is used exclusively by appointment.

Roofing of rolled materials

In order for the roof to be implemented according to all standards and rules, follow the phasetance of its installation.

The sequence of assembly of the rolled roof design:

- Installing the basis - concrete overlap or solid type crates.

Important! The roof with the slopes tools with a crate of moisture-resistant plywood or edged wooden plates. All lumber before installation are processed by antiseptics and dried.

- Laying a vapor insulation membrane that protects the layer of insulation from condensate coming from the inside of the room.

- Installation of thermal insulation.

Important! It is often used extruded polystyrene foam and tiled mineral stone wool, but the use of bulk mixtures is allowed on flat roofs.

- Pouring cement screed layer thickness from 20 to 70 mm.

- Installation of decorative coating in 2-5 layers.

Proper laying of the rolled roof

The technological process of laying roofing roll material in many steps depends on the angle of inclination of the roof.

The number of roofing layers are calculated in this way:

Width of the adhesive stripes of the canvas:

- more than 5 ° - withstand overlap 80 mm for internal and 120-150 mm for exterior layers;

- less than 5 ° - influx of layers from 100 mm.

The location of the sections of the material:

- On the roofs with the slope slope \u003c15 ° - parallel to the skate, ranging from the bottom of the outlet. A piece of sliced \u200b\u200brolled cloth is mounted on the horse.

- At the pitched corner,\u003e 15 ° has a strip perpendicular to the skate. The upper edge of the canvas is transferred through the horse, and the lower indent - from 15 cm. Such a technology is observed to arrange all the rods.

Important! Do not lay the layers in different directions, especially on the roof with a zero slope.

Methods of fastening

There are several methods for fastening materials such a category:

- Mechanical. The canvas is attached to the basis of roofing nails. Often it is used to fix the lining first layer.

- Claimed. The installation of rolls is carried out using a gas burner that melts material from the side of contact with the basis. Tightly glued after pressing it to the base.

- Installation on bitumen mastic. The base is labeled with a dense layer of a cold solution, on which the strips of the material are glued.

- Self-adhesive roofing materials. The lower layer of materials under the influence of the Sun melts, after which it is tightly pressed to the base of the roller on the sections of the joints and the adhesive.

Important! The most frequently used attachment method today is said. Self-adhesive materials are much more expensive, so they are used less often.

Mastech preparation methods

Mastic for fastening roofing ornamental materials is cold and hot.

The cold solution includes:

- 40% bitumen;

- 40% kerosene or diesel fuel;

- 20% of the filler (asbestos chip or hated lime).

Important! The mixture is prepared as: the container with pieces of bitumen is heated to 160-180 ° after which they are dehydrated. In another ideon, the filler with a diesel fuel thoroughly mix. The resulting mixture add melted bitumen and stirred to homogeneous mass. Wait for the technical pause before applying required to cool the solution.

Hot mastic consists of:

- 80-90% bitumen;

- 20-10% filler.

Important! To prepare such mastic, bitumen in the tank is heated to 220 ° and the filler is added gradually. When the composition starts to foam, the "sacc of" remove unplanned bitumen particles that have surfaced to the surface. Mass are thoroughly mixed until it acquires a homogeneous consistency with a mirror surface. When the mastic cooled up to 160 °, you can proceed to applying it.

Roll roofing: Intrusting Mounting Technology

Installation of the roof roller is often performed by the method, especially on the roofs with a flat surface. Stacking, strictly observing the following sequence of actions.

Stages of laying rolled roofing

To equip the roof of your home with a roll coating, be sure to clearly follow the sequence of work. It is impossible to change the phase of treatment of elements that looks like this:

- drains;

- rowlings;

- livneeRechnics;

- vaporizoation;

- thermal insulation;

- reinforcement;

- screed;

- aerators;

- waterfront funnels;

- roof area;

- complex elements - pipes, auditory windows, horse;

- clamping plank;

- parapedes.

Installation of roofing cake: instruction

- Remove the old coating layer, if any.

- Eliminate all the garbage, dirt and dust.

- Close the repair solution of the gap, chips, and wait for drying.

- Install livnemics and drainage.

- Place the vapor insulation material, withsting the backstage of 10-15 cm.

- Clean the joints of the construction scotch.

Important! Parosolation is placed so that the future layer of the heat insulating membrane is located below.

- Installation of thermal insulation Perform in 2 layers by closing the joints of the stoves.

Important! Compliance with this rule will help prevent cold hit.

- Fasten the insulation with special dowels or gluing.

Important! The joints between the heat-insulator plates will be mistaken.

- On top of the insulation, pour the alignment screed with a layer thickness of 20-70 mm.

- In the screed, perform temperature and shrinking seams with a thickness of 0.5 cm, and linear seams with a size of 6 * 6 m.

- Roof joints with vertical parts, place 10 * 10 cm with cement sides (width and height).

- Look around for about 6 hours to dry the screed.

- Apply a purchased or independently prepared primer.

Important! If you decide to prepare the primer yourself, mix the same bitumen and kerosene proportions.

- Wait for the primer drying.

- Waterproof temperature and shrinking joints - cut the material strips of 150 mm wide and glue them to the base, wrapped with bitumen mastics.

- Roll off the roll on the future mounting site and check it on integrity.

- Heat the edge of the canvas with a gas burner and press it tight to the initial edge of the base.

- Roll back to the glued place.

Important! Adhere to the following laying technology in the process of performing work: one person gas burner gradually warms up the base and glued side of the canvas, the second turns a roll with a hook, and the third - presses the material to the base with a rink. Please note that a properly preheated bitumen should perform on the edges of clots with a thickness of 20 mm.

- Bad branded edges. Holt with a spatula, warm the burner and stick again.

- The following canvas are glued with an adequation of the adolescence of 10-15 cm.

- To put the material on Parapets, the upper piece of the cut band is attached with nails, and then glue with a melting web.

- Putting the material around the waterfronts of the drainage, cut the pieces of the material and glue them so that they form squares with a size of 0.780.7m.

- Subsequent layers are mounted similarly, not forgetting funnels and parapets.

Important! Place the material layers solely in one direction. After the first layer is glued and before installing the next, it is recommended to wait 12 hours.

Video

Check out below the proposed video styling of the roll roof this method to eliminate any questions when installing.

Laying rolled roofing with a cold way - distinction

Laying the cold roof is slightly different from the hot method.

Installation instructions that describe the differences in technology:

- Before mounting, expand the roll, leaving it for a day. In the absence of this feature, roll a bundle and roll it in the opposite direction.

- Installation of the first roll is performed as follows: Roll the coach of material to the middle and check if it is enough to the initial place of laying, and then the deployed piece is repaid again into the roll. According to the result, one roll must be rolled in 2 rolls.

- One person is missing the base of the mastic in the place of laying.

Important! It is recommended to process no more than 1.5 square meters at a time.

- Another employee rolls the material based on mastic.

- The longitudinal beet should be about 10 cm, and the back of the end is 15 cm.

Important! The laying of membrane rolled cloths are attached to the cloak (more expensive procedure) or a mechanical method. The layers of the membrane roof are welded by a special apparatus.

Arrangement of complex places - Promotions to vertical surfaces

The most difficult process when installing the rolled material on the roof is considered to be the design of the junction connecting places with vertical parts through which moisture can fall. These sites have 2 layers, which make it as follows:

- Cut a piece of roll width sufficient to cover the vertical part by 0.25 m.

- Upper edge fasten with nails.

- Stick the canvas to the base.

- The second piece cut the width covering the vertical part by 35 cm.

- Roll down the top edge into a bundle of 5 cm, attach to a vertical basis and secure the bar.

- The rest is a piece of the panels, and glue to the base.

Conclusion

As you already understood, the entire process of installation of a rolled roof is quite accessible to self-execution, despite the fact that it will require significant time and special accuracy. If all the work is done in a clear sequence, painstakingly and carefully, durable and reliable roof will delight you at least 15-20 years. Pay attention to the quality design of the roof, because this largely depends the strength of the entire home and the preservation of a comfortable microclimate inside the house.

To finally be convinced by the correctness of your decision, read the advantages that all rolled covers differ:

- high plasticity;

- resistance to low temperatures;

- solid foundation;

- wide attachment capabilities;

- light weight rolled roofing;

- simple installation and repair;

- long-term conservation of all characteristics.