Concrete staircase with your own hands Ladder

The staircase in the house is not only a functional element, but also a part of the interior defining a certain style. The main requirements for any staircase are reliability, aesthetics and safety. Concrete structures meet all these criteria, especially if you know how to contact them. The cost of ready-made concrete stairs is very high, but if desired, it is not so difficult to make a similar item with your own hands. In this article you will learn how to make a staircase from concrete with your own hands.

Design features

Concrete stairs are considered to be the most reliable compared to designs from other materials. They are not loosened, are not susceptible to rotting, damage to parasites or dryness, are able to withstand enormous loads. When mentioning the concrete stairs, most people imagine gray spans in the entrances, but if you approach the case competently and with a drip of fantasy, you can reap the concrete surface so that no one will ever think to call it boring and ordinary.

Monolithic stairs from concrete can be installed anywhere, whether it is a supermarket, plant, office or private house. If you decide to make the design with your own hands, you will not need significant financial investments or specific skills - all work is quite simple.

But to understand how to make a staircase from concrete, you need to understand the features and varieties of structures. So, distinguished monolithic and combined stairs. In the first one-piece design, and only concrete and fittings are present in the composition. They are installed in cellars, entrances, on the porch, etc.

Combined stairs have a more complex structure, since they are based on a metal frame, and only steps are made from the concrete. The steps are cast using a special formwork and reinforce the grid for strength. As part of concrete, in addition to sand and cement, a crushed stone must be present - it makes the material more durable and resistant to destruction. Alternatively, rubble use granite or marble crumbs. After drying the cast stage, it is polished and covered with hydrophobic primer deep penetration.

Calculation of stairs

An important role in the arrangement of any ladder plays the calculation. In order for the design to be convenient to use, gently enter it into an existing interior and fit under the size of the room, you need to calculate the total length, height, dimensions of the steps, the angle of inclination, etc. Of course, there are generally accepted standards, but they are not always able to apply them, especially if we are talking about premises with non-standard sizes.

The appearance of the product depends on the geometry of the room and your own fantasy, but at the same time it should be constantly remembered that the more complicated the design of the ladder from concrete, the harder it will make the calculation for it and install. Therefore, newcomers are better to start with what is simpler.

The main stages of the calculation:

- Determine the position of the staircase - where it will be (on the ground, near the wall, between the two walls, etc.). It is these nuances that determine the subsequent calculations and the installation of the staircase with the formwork.

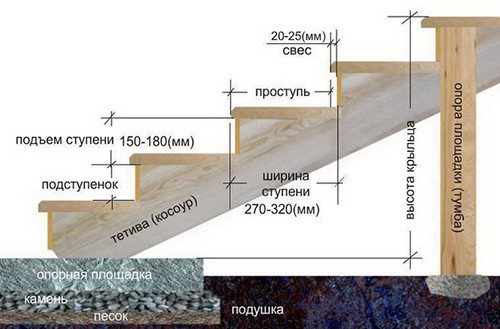

- Calculate, from how many steps will be a staircase, and what will be their size. Typically, the height of the stage is from 16 to 20 cm, and the width is not less than 27 cm. In the width, the step should be fully placed in a feet of an adult, and this is at least 27 cm. If the number of steps in the stairs exceeds 14 pieces, it is better to make it from two spans. The height of the steps is also very important. So, the elderly people and children will be difficult to climb the stairs with high steps.

- Determine the angle of inclination of the stairs. It can vary from 25 to 45 ° and more, but the steeper the staircase, the harder it is to go on it and more dangerous.

- The minimum staircase width is 50 cm, but it is desirable that it does not exceed 90 cm, otherwise the design will be too cumbersome. But if you have plans to make a luxurious wide rise to the second floor, your right to realize your original idea of \u200b\u200blife.

- Concrete weighs a lot, so consider the mass of the finished design and the load on the foundation, based on the fact that 1 m² of concrete is 20 cm thick weighs up to 500 kg. Thus, a ladder march with a length of 4 m and a height of 2.5 m and a width of about 1 m will be weighted up to 2.5 tons. We do not recommend making the fill of the staircase from concrete on a tie, insulated foam or polystyrene foam, since it can be sold surface . Due to the large weight of the design, it is better to install it on a very dense base.

Choose high-quality components for the preparation of the solution. Good cement is not so expensive, so it should not be saved at this moment. To prepare the solution, mix 1 part of the cement (concrete brand for the staircase is not lower than M400) with 2 parts of manual sainted sand and 4 parts of the crushed stone, granite or marble crumb. To increase the elasticity of the mass, you can add a special plasticizer.

Useful advice: After filling the concrete, fine air bubbles will necessarily be formed in an unrestal mass, which reduces the strength of the structure. To destroy them, use a special vibrator for concrete. If it was not possible to get such a thing, let's stop the mass with a wooden stick in several places.

After filling and vibration, cover the raw concrete with polyethylene so that the moisture from it does not evaporate too quickly. Otherwise, the surface may crack. It is periodically recommended to sprinkle with a drying staircase with cold water from the pulverizer until the concrete is completely frozen.

The formwork can be removed no faster than after 3-4 weeks, when the concrete will freeze at 80% and can withstand its own weight independently. By the way, the duration of pouring concrete is the main disadvantage of such stairs, but the result is worth it.

Construction technology

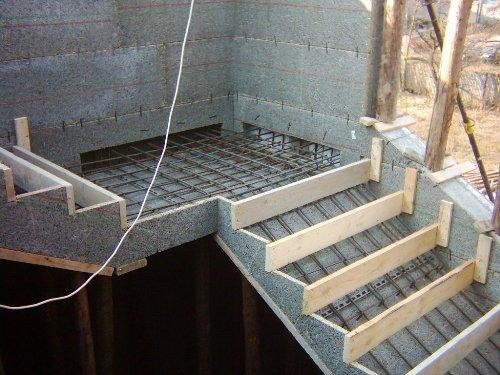

The most complex in the manufacture of the staircase from concrete is to properly build a formwork. The final result depends on its evenness and tightness, so they need to act with knowledge of the case. Mounting complexity depends on the geometry of the future design.

The easiest option is a staircase placed between two walls. Walls will serve as an additional support for formwork. You only need to designate the contours of the steps on the walls and attach the formwork according to this markup. In other cases, it is necessary to collect lateral formwork.

It is also easy to make a single-sighted staircase from concrete to the second floor with a rectangular cross section. Compared with the previous option, you will need to add at least one side formwork and make support for it. As for the decorativeness of such a simple design, it can be achieved thanks to successfully selected finishing material, but we will talk about it a little later. You can also make the steps of an unusual form, for example, rounded or wave-like.

But, unfortunately, in most cases, to fit the whole single-hour staircase in the house does not work because of the characteristics of the planner or its ineffibly large sizes. In this case, you have to make two march with running steps or a turntable. The formwork for such a staircase is more difficult because it is necessary to collect an additional frame for the site or running steps, after which it is difficult to fix all the elements on the bearing wall of the railway with a crown or put the support columns.

Many are the most beautiful and stylish, many consider screw staircases from concrete. Such an element will decorate any interior, but it will be quite difficult to make it novice. Professionals are taken for the construction of a spiral staircase from concrete more than 1000 dollars per 1 m of the rise, and not surprisingly, since the formwork for it consists of a variety of curvilinear shields, and the work is very laborious. In addition to the specific formwork, you will need to make a large amount of supports and the most complicated metal frame from the reinforcement.

The video shows how to pour a concrete ladder for a spiral design:

We offer in general terms to consider how the formwork is set. First of all, we need to stock consumables: moisture-resistant plywood (the usual will take moisture from the cement mortar, and he cracks) with a thickness of 20 mm and a constructionar 100x100 mm.

To make a formwork of a monolithic structure, you will need the following:

- wooden bars to fasten the formwork parts between themselves and fixing them to the walls;

- segments of timber for connecting steps and imparting formwork (do not allow shields to stretch after filling the solution);

- shields for the formation of running steps (with a length of a stage in 1 m of plywood should be a minimum thickness of 30 mm, with a length of 1.2 m - at least 40 mm);

- elements of the end formwork are plywood shields or a pre-prepared pattern. The thickness of the elements should be about 30 mm.

For fastening parts of the formwork, the vehicle tapping screws most often use, because then it is easier to extract them than nails (you still have to disassemble the formwork).

The main rule of any formwork for a concrete solution is the lack of cracks and gaps, so all the details need to be customized to each other as thick as possible. If the slot was still discovered, it should be poured with silicone sealant and pour the solution only after its complete drying. Before pouring the solution inside the formwork, it is necessary to put the reinforcement framework. Without it, the staircase can hit his own weight. First, over the perimeter of the staircase, the steel bars are placed, after which they combine them cross.

As we have said, collecting a formwork for a staircase is the most difficult. And when this stage is already behind, it remains only to fill the forms with concrete. For the manufacture of high-quality solution it is better to use a concrete mixer or a building mixer. It is very important to concrete the entire design at a time. Otherwise, the place of contact with the fresh concrete with the fresh will be a potential risk point, and with time, most likely, the crack will appear there.

Useful advice: After the fill, be sure to treat the concrete vibrator, but do not touch the reinforcement inside, otherwise there is a cement "milk", which will reduce the strength of the design and the adhesion of the solution with a metal frame.

How to prepare a concrete solution for filling the stairs:

- At first, download the necessary amount of rubble or stone crumb into the concrete mixer.

- Add cement with river sainted sand.

- Allow dry components to shiver with each other, turning on the concrete mixer for 1 minute.

- Gradually add cold water by achieving the desired gym consistency. After 2 min. Stirring solution will be ready to use.

IMPORTANT: Do not forget to cover the staircase with polyethylene after filling and vibration, so that the concrete does not crack!

After that, it remains only to gain patience and wait for a complete drying of concrete. It will take about a month. Do not go on the stairs all this time! Even when after 3 weeks you remove the formwork, it is still impossible to step on the steps.

And finally, the staircase from concrete is ready, but it looks not too present. Here, it begins the most interesting and creative stage of work - decoration. For decoration of the concrete ladder, you can use laminate, tile, clinker brick, mosaic, parquet and wooden panels. If the interior is decorated in the Loft style, it is possible to leave the "naked" concrete at all, but that it is not dust, it is better to cover it with a special polymer composition.

Very nice looking stairs made of concrete, completely trimmed with wood - it seems as if they are made of a single wooden array. The variants of the design mass, and at the end of the article you can see a small photo generation of original ideas.

Finally, a few useful tips How to pour a ladder from concrete:

- Remember that concreting should be done in one reception, so immediately prepare the required amount of solution.

- Pour concrete into a formwork, starting from the top stage of the stairs and gradually moving down.

- After concreting each top stage, you immediately process the vibrator solution - then you will not be able to rise above.

- To make a solution more viscous and fixed, add rubbank or marble (granite) crumb fractions 10-15 mm into it.

- The cement brand for the preparation of a concrete solution should be no less than M400.

The technology of stairs from concrete is quite simple, if you understand, however, the execution requires skills and definite skills. If you do this for the first time, you should not immediately wait for complex designs, despite their beauty and style.

Concrete stairs: Photo