Submersible pumps for wells Plumbing

Submersible pumps for wells are an excellent option to ensure itself and the economy of high-quality drinking water. However, not the entire range of the market is equally well cope with the task. Therefore, it is important to properly approach such a serious matter as the selection of the immersion pump for the well.

Content

Preparatory stage

To begin with, collect information about your well. Main parameters:

- well diameter

- well depth

- dynamic water level,

- static water level.

If there are no additional questions with a diameter and depth, then with water levels should be understood in more detail.

The dynamic index or potential of the well is a specific volume of water that can produce for a certain time. The indicator affects the power of the pump.

Static water level is the distance from the ground to the water surface. This parameter defines the minimum height to which the pump should supply water.

Another important point is the supply of power. If you plan to use the pump not regularly, there will be a fairly ordinary extension cord. With continuous operation of the pump for one hour or more, it should be equipped with a stationary electrical outlet.

With long-term operation of electrical appliances through the extension, there is strong heating, both the cable itself and forks. As a result, the protective elements will begin melting, which will lead either to the closure or damage to isolation. In the first case, it will take the repair of the entire pump, in the second, when contacting the device, it is possible to obtain a shock.

The main characteristics of submersible pumps

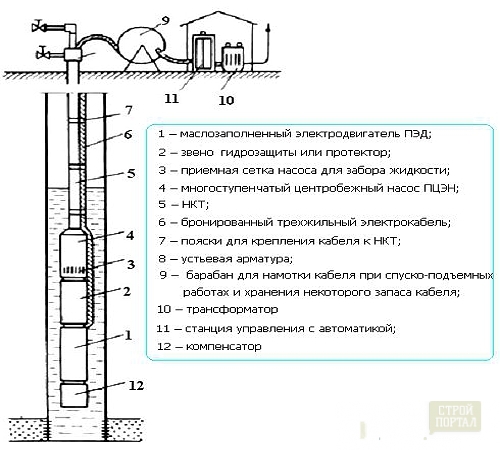

All submersible water pumps for wells are arranged equally. Basic elements:

- motor,

- frame,

- water supply system

- underwater and tap tubes,

- float for automatic shutdown,

- electrical cable for connecting to the network.

Depending on the manufacturer, the appearance, size and technical characteristics can be hung, but these basic elements should be in any high-quality submersible pump. Much more important than the immediate characteristic of the pump:

- Principle of operation. Pumps are divided into vortex (low power), centrifugal and auger (used to supply technical water or pumping fluids containing sand, or other small solid particles).

- Specific power. Consumer pumps are from 250 W to 5 kW, industrial analogues can significantly reach 100 kW. When choosing a power, it should be noted that the standard electrical system is designed for the maximum load of 3 kW, if the power consumption is greater, or the automata will turn off, or the wiring will burn.

- Performance. Determined by the amount of water that the pump can serve in a certain time interval. The parameter is only indirectly associated with the power of the pump, since it depends on the bandwidth (the diameter of the input valve).

- Peak. Height for which the pump can pump water. The value indicated on the model corresponds to the static water level.

- Temperature mode. Most domestic pumps are calculated on the flow of cold water. But, some manufacturers make combined models, which affects the cost. Often the hot water pumps are used in production or in thermal sources.

- Rigidity. It is understood by the presence of solid particles in the pumped liquid.

- Test material. The pump housing is manufactured, as a rule of stainless steel, it can additionally be trimmed with plastic. The characteristics of the steel itself depends in which environment the pump will run. The subspeted waters contain many salts, so for the wells it is better to choose a pump specially intended for these purposes.

- Weight. From this parameter depends on the pump mounting. Light (up to 30 kg) models do not require additional structures, but for heavier it will be necessary to build special attachments.

Method of installation of submersible pumps

Selecting the submersible pump for the well, it still needs to be installed and connect. This procedure is very important, since in non-compliance with the requirements there is a risk of premature motor breakage, or in a consequence of overheating, or due to water from entering the pump unpredictable for this.

There are two types of fastening:

- cable

- stationary.

Installation of the submersible pump in the well using the cable is carried out according to the following scheme:

- measure the distance from the ground to the water surface,

- buy hydrocabar of the corresponding length,

- connect the cable to the pump with a special hermetic clutch,

- prepare a cable

- prepare a submersible mechanism (or lower and raise the pump manually),

- fasten the cable on the pump and the immersion mechanism,

- connect the flexible rubber hose to the exhaust valve.

Installing the submersible pump in the well using stationary attachment involves the execution of all previous steps, with the addition of one more - mounting the mount.

This mechanism can be performed in two variations. Option number one is suitable for those who use the pump not regularly:

- prepare a metal pipe of the corresponding length,

- weld to the upper and lower edge of the slider by creating a block system,

- take the rope in the block,

- make a loop on the rope for fixation,

- on top, at a convenient height of welding a stopper (the simplest option is a straight piece of the pipe on which the rope will be fixed),

- at the necessary depth to install the pump and firmly fix it on the rope,

- install the metal pipe into the well so that one end to the bottom of the bottom, and the other from above.

It should be remembered that the electrocabel must be securely fixed on the pipe either with the help of a tape or special clamps.

Semi-automatic lift ready. The feasibility of creating such a design is manifested when the pump is used for irrigation. For these purposes, an inexpensive version of steel with weak anti-corrosion indicators is suitable. You can not constantly hold such a pump in water, but omit and raise it manually - inconvenient.

The second way implies the use of a high-quality pump, which is intended for permanent location in the aquatic environment and is to create a personal water station. The procedure is similar to a cable system, only instead of the hose, a metal-plastic tube is used, which simultaneously serves as a pump lock.

The best manufacturers of submersible pumps for wells

For submersible pumps for wells, prices are offered from quite democratic, to quite expensive. The cost is influenced by power and, naturally, the company manufacturer. Evaluation of the wound and monitoring of submersible pumps for reviews for reviews make it possible to make clear conclusions and offer the best options.

Let's start with the cheapest. This includes the products of Chinese manufacturers. Private firms usually order pumps in China and sell them in their boxes. Understand where the device is made, it is enough just to inspect the housing itself. It will definitely be chosen "Made in China".

These aggregates will suit those who plan to use the pump for watering during the hot season. Of the advantages, only very low cost, which allows not to repair the pump, but throw out and buy a new one. Work in seasonal mode it can from 3 to 5 years. Why not fix it? First, it is difficult to find masters, secondly, the cost of the work may come close to the cost of the pump itself.

Since firms offering this products are very much, we will not stop at them and consider the European manufacturers, whose technique is designed to work in Non-Stop mode.

You should start a review with the Italian company NOCCHI. It specializes specifically at the production of equipment for wells and wells. The price policy is based on 8,000 rubles. In addition to all Italian, impeccable appearance, the serial line has high reliability and ease of use.

The main stop developers are on the pumping of drinking water, so making the choice in favor of Noocchi, it should be remembered about it. I am glad and a wide network of service centers, which are located in all major cities. The only minus is the length time of the part, if something breaks. But this deficiency is inherent in all corporate instruments.

Perhaps the most authoritative manufacturer of submersible pumps is another Italian company ZDS. Many years of experience and its own design bureau provided a company recognition worldwide, since there are no more reliable pumps. But this circumstance greatly affects the price order, the model range begins from 600 euros. The pump repair is rare, but if necessary, it will be very expensive.

Another Grandmaker, which does not need any ideas is Alfred Kärcher GmbH & Co. KG or just Karcher. The world's largest water management company is not just for many years holding a palm of championship.

Submersible German pumps for wells, although they are just one small clause of the model range, but made with special pedanticity. There are no eternal things, although the carriage products are very close to it. Perhaps this is the only manufacturer who justifies overpays for the brand. The highest quality, durability, availability of services in any city, lightning repair - all this makes Kärcher the best.