Steps from porcelain stoneware for stairs do it yourself Ladder

For finishing steps of the staircase you must choose a versatile material that will trudnostiraemym, fit the interior and not afraid of moisture. This material is a ceramic, which appeared on sale recently, but has already received widespread due to its universal quality and indisputable advantages. In addition to working with him is no big deal and facing granite steps can be carried out by hand.

Content

Granite, its advantages and disadvantages

Porcelain tiles produced by artificial means, though, but from natural materials such as clay, sand, quartz, mineral pigments. Thanks to this composition, this material is environmentally friendly, does not emit harmful substances and not dangerous to human health. Therefore, it is ideal not only for outdoor, but also for interior decoration.

The main advantages of porcelain, which distinguish it from other materials:

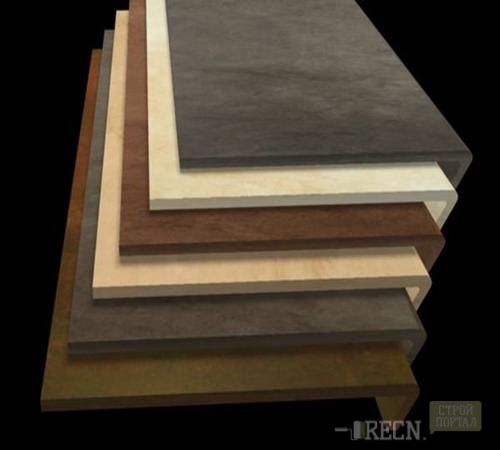

- a huge variety of colors and textures allows you to simulate virtually any surface, from wood to stone;

- watertight. Inside material lacking even the smallest voids due to the fact that it is produced under high pressure. Therefore, the material can be used in any environment, including the open air;

- resistance to temperature extremes. density of porcelain structure is such that its destruction, both at low and at high temperatures, completely excluded;

- not being exposed to chemically corrosive environments. Neither household chemicals, nor many of the more dangerous substances are not able to damage the structure of the material;

- infertility abrasion. Porcelain is extremely heavy, with many years he will not fade and does not change the drawing. This happens because it is not applied to the surface of the material, but passes through it;

- apply mechanical damage is extremely difficult, it is possible to leave scratch only diamond;

- does not require complex care.

But there is a ceramographic and its drawbacks, for example:

- cold surface and at the same time the impossibility of insulation. For the facing of street or shop stairs, this deficiency is not important, but for the stairs in the residential premises, it is a serious minus;

- if the texture of porcelain stoneware is not a rough, the surface is quite slippery, especially in a wet form, which means dangerous;

- high cost of porcelain staples for stairs. Its price is a lift far from all, although, in the end, expenses are justified for a hundred percent.

Stair treads of granite

If you want to make steps out of porcelain stoneware, then you need to know that they are two species:

- whole;

- suture.

Standard alloy stages can be bought in stores, but if you have an individual size, you can make them to order. Steps that do not have seams, outwardly much more beautiful and spectacular than suture. The front edge of such steps is direct, semicircular or relief.

The set of suture steps consists of the following elements:

- ceramic corner - cornice;

- attack - located horizontal plate;

- retreats - tile located vertically;

- plinth.

Such kits are frontal, basic and angular, and may also have different sizes.

Ceramic corner, it is the cornice, in a one-way version is part of the monolith, and in a set - a separate part. Mounted steps on the finished staircase - metal, brick or concrete.

Stair finishing technology with porcelain stoneware

Installation of various types of porcelain stages has its own characteristics:

- if your choice fell into one-piece steps, it will not be necessary to stick the parts, customize them to each other, but it is necessary to take care that the basis for which the material is mounted is perfectly even and geometrically verified;

- if you use a set option, then you can always roll out separate parts of the design and customized for the desired size, as well as combine shades and colors. But at the same time such a way more work.

Sequence of installation of any kind of steps of porcelain stoneware :

- before proceeding with work, it is necessary to check whether the material has been purchased enough in order to bind the desired area;

- to customize and dock each other elements of a porcelain design structure, it is better to use a water-cutting machine. Only he does not create chips and does not provoke the appearance of cracks;

- to improve the coupling of steps and material, they should be covered with acrylic soil of deep penetration, first cleaning from dust and contamination;

- the tile should be laid on a special glue composition for porcelain stoneware, which is applied with a toothed spatula. At the same time, the work should be started upstairs, gradually moving down. Spreading the glue for fastening the material, you should strictly stick to the dosages recommended by the manufacturer.

If you are placing the steps consisting of individual parts, then in addition to the actions described above, such:

- in order for the joints between the details were perfect, the porcelain stoneware should be either twenty with steps, or exceed them in width;

- if the side stage is issued, then you need to measure it, using a grinder and turbo-disk;

- first of all, the attacks are put, carefully equals, and then the approaches and eaves;

- at the last stage, the plinth is mounted. When they are styling, it is necessary to remember that they can be both right and left-sided.

Porcelain stoneware is very reliable and at the same time universal and thanks to these properties, it is successfully applied not only for facing stairs inside the premises, but also in the open air, as well as in public places: shopping centers, theaters, cinema halls, etc.

If the installation of porcelain stoneware is made on street conditions, it is necessary to think about protecting the steps from adverse weather conditions:

- porcelain stonewares for stairs on the street is usually equipped with a small wastewater located in the side part, which prevents the depression of moisture on the surface of the stage;

- the corners of the steps are protected by a rubber profile that does not give to apply to the tax.