How to make waterproofing the pool from the inside Baths, saunas and pools

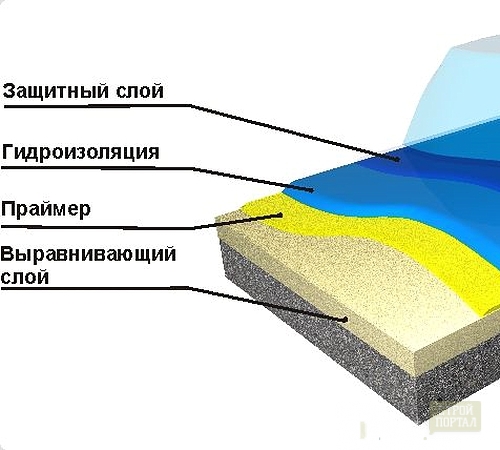

When a new or restoration of the old pool, a mandatory point is the correct installation of waterproofing. It is very important to fulfill all the work carefully and consistently, because this will depend on the life of the reservoir. In this article, we will look at how to make waterproofing the pool in different ways, as well as the advantages and disadvantages of these methods.

Content

- Functions of the internal waterproofing of the pool

- Varieties of waterproofing of the pool from the inside, their advantages and disadvantages

- Arrangement of concrete waterproofing

- Arrangement of waterproofing with PVC membrane

- Pool waterproofing liquid rubber

- Pool waterproofing with liquid glass

- Waterproof waterproofing

Functions of the internal waterproofing of the pool

1. Protective function. The internal waterproofing of the pool is performed to protect the concrete bowl from the effects of moisture. Water has a large pressure on the bottom and the walls of the reservoir, and if not to install waterproofing, cracks will appear on them. Waterproofing is a shell that prolongs the life of the pool.

2. Antiseptic function. Waterproofing acts as an antiseptic that prevents the fungus and mold on the surface of the pool. Accordingly, harm to human health, bathing in it, turns out to be minimal.

3. Waterproofing facilitates the washing of the pool. It becomes much easier to clean than, for example, concrete reservoir.

4. Aesthetic function. Waterproofing improves the appearance of the pool and in many cases the finish is no longer required. All sorts of PVC films perfectly imitate tiles, mosaic or seabed.

Requirements for waterproofing of the pool:

1. For long use of the pool, waterproofing should be durable. After all, when it is destroyed, it is necessary to restore the entire structure completely.

2. Elasticity is another important quality that waterproofing should have. The pool bowl is under constant pressure, and this property contributes to its uniform distribution over the surface.

3. Strength. This characteristic depends on the service life of the basin, its exposure to various impacts.

4. High adhesion indicator, which is necessary for reliable fastening of waterproofing to the bowl surface.

5. Monolith. The lack of seams on the waterproofing structure ensures the qualitative implementation of all of the above requirements.

Varieties of waterproofing of the pool from the inside, their advantages and disadvantages

1. Concrete waterproofing is performed using a special hydraulic cement. Its advantage is strength, monolith, durability, as well as the ability to embody designer ideas, create various forms of the bowl. The disadvantages of such waterproofing include a long term manufacturing and drying of concrete, large material investments and labor costs.

2. PVC film. Advantages of installing a film for waterproofing of pools: aesthetic appearance, durable and smooth seams, the possibility of mounting on an uneven surface. But along with a lot of benefits, there is a serious drawback - a small strength and vulnerability before mechanical damage.

3. Liquid waterproofing for pools - rubber. It forms on the surface of the pond monolithic layer, which is quite durable, but at the same time soft and elastic.

4. Liquid glass. The surface of the basin impregnated with this material is characterized by the presence of protection against moisture, ultraviolet and corrosion. The lack of such waterproofing is a briefness.

5. Benefits of inlet waterproofing: frost resistance, strength, elasticity. The disadvantage is a rather time-consuming process of work and a perfectly smooth surface.

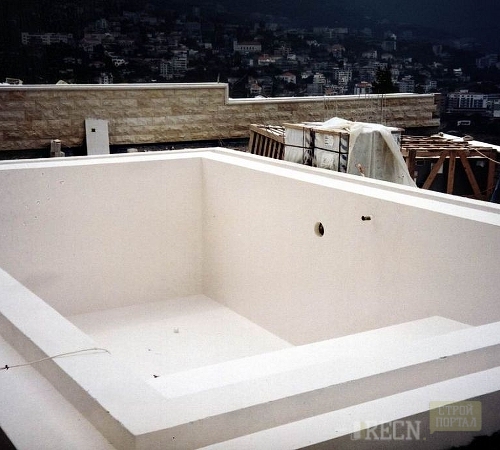

Arrangement of concrete waterproofing

For waterproofing of pools, concrete with the addition of various impurities is often used under the tile. Varieties of impurities for concrete:

- penetrating the mixture for waterproofing of pools - added to cement mortar for deep penetration into the structure of the bowl;

- waterproof plaster is an excellent option for leveling the base, embedding all seams and cracks;

- polymer-specific solutions - differ in good vapor permeability and moisture resistance, light in operation, are applied using a roller or brush;

- adhesives or grouts that increase the waterproofing properties of concrete.

Application of waterproof plaster on the walls of the pool is a rather complicated process for which you will need:

- spatula or trowel;

- ironing;

- rollers for applying an anti-corrosion coating;

- capacity for plaster;

- net,

- lighthouses.

Before starting work, apply an anti-corrosion solution on the walls of the basin, and then the adhesive coating with a roller.

Set lighthouses and attach the grid.

Apply a cement mix on the side of the reservoir. Its layer should not exceed 3 cm. Align the surface according to the mounted beacons. After complete mortar drying, make the pool finish. Only after decoration the pool is filled with water.

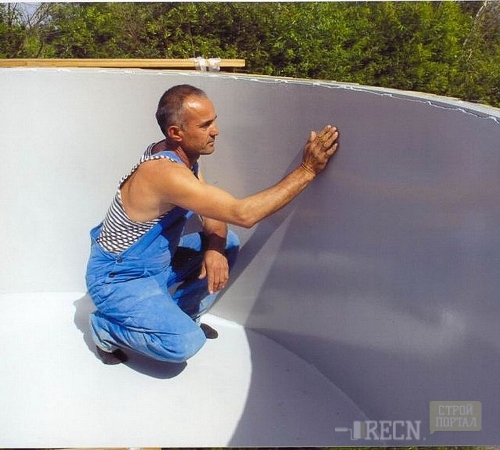

Arrangement of waterproofing with PVC membrane

Installation of waterproofing PVC membrane is carried out quite quickly. Materials will require such:

- film substrate;

- glue;

- film;

- seal of seams.

Instructions for installing PVC films for waterproofing of the pool:

1. With the level of level, measure the evenness of vertical and horizontal walls. The maximum permissible drops horizontally are 2 mm, and vertically - 3 mm.

2. If the differences exceed the permissible norms, the surface should be aligned using a putty or cement solution.

3. Installation of the film is carried out not only on the concrete surface, but also on the tile base, in case it was worn out during operation.

4. The basis for laying a pool film - durable and strong boards.

5. Secure the substrate under the film. Use stainless or plastic flanges and rubber linings in order to avoid corrosion. Fixing linings is possible with glue.

6. The mortgage film is located no closer than 30 cm from the corners and edges of the pool. Its function is the protection of PVC membrane from abrasion about the concrete surface.

7. In terms of the edges of the bowl, the holes under the dowel are drilled and the PVC film is installed. Installation is made by welding.

8. In the place where the film is joined with each other, it is necessary to make a quick heating, and then the compression of the material and the compound of the seams.

9. The seams are additionally processed using the seal.

10. Then gradually the pool is filled with water. Recommended water temperature is 40 degrees. The first filling is 35-40 cm. Next, the response flanges and the pool fill completely.

Pool waterproofing liquid rubber

For waterproofing of the pool with complex geometric shapes, the ideal option is liquid rubber.

This meterial has a lot of advantages:

- lack of seams and joints;

- good waterproof;

- elasticity;

- fast installation;

- does not react with chlorine.

Pool Waterproofing - Liquid Rubber Application Technology:

1. Clean the base of the pool from small dust particles. Take all cracks and seams with a cement solution or putty. If necessary, degrease and drive the surface.

2. Apply liquid rubber without a hardener with a roller, brushes or compressor.

3. Apply rubber with a hardener and crumple the surface. Maximum layer thickness - 2 mm.

4. Avenience after applying rubber, fill the pool with water.

5. Switch the water and run the last step of the rubber. After that, the pool acquires the final aesthetic appearance and color color.

Pool waterproofing with liquid glass

Pool waterproofing with liquid glass not only reduces moisture absorption, but also increases the stability of the surface to mechanically damage.

For work, the material is used both in its pure form and in connection with concrete, in the proportion of 1:10.

Advantages of waterproofing with liquid glass:

- protection from the formation of fungus and mold;

- antiseptic and anti-corrosion protection;

- reliability in the clutch;

- ease of use;

- affordable price;

- small consumption of materials.

At the stage of filling with concrete, to increase the strength and waterproofing of the pool bowl, liquid glass is added to the solution. They also impregnate the walls of the reservoir. This ensures its protection against moisture, the sun, the temperature drop and corrosion. Liquid glass protects the pool walls 4-6 years.

Waterproof waterproofing

For carrying waterproofing, special rolled materials from a polymerized bitumen are used.

Before starting work, align the surface and clean the walls of the pool from dust and dirt.

The waterproofing sticker is performed using bitumen-polymer or bitumen-rubber mastics. The bitumen softened to a temperature from 40 to 250 degrees, depending on the quality of the materials.

The dry base for bitumen mastic is applied to the surface by a layer of 1.5-2 mm. The roll of the material is rolled over the surface of the mastic and fasten it. It is possible to use multilayer waterproofing. Then, after rolling, the roll again applies mastic, and then rolled material.

On vertical walls, waterproofing is applied from top to bottom. The maximum roll length is 10 m. For connecting the joints, the burner is used.

As a rolled material, hydroize is used - double-sided or one-sided.

Pool waterproofing video: