Installation of ventilated facade of porcelain Construction

Under the influence of atmospheric precipitation and temperature drops, the walls of structures are destroyed. To protect buildings from the influence of weather influences, the decoration of external walls is used. Popular modern technology for facing new buildings, as well as reconstructions are ventilated facades, a characteristic feature of which is the presence of a layer between the walls for circulating air and evaporation of excess moisture. In addition, such a system effectively insulates the building and serves for its decorative decoration.

Content

Benefits of ventilated facade

As materials for the system of ventilated facades, it is used: natural stone, composite materials, as well as modern material of porcelain stoneware, differing from other facade materials with increased strength and high thermal insulation properties.

The following benefits of these facades can be called:

- such a system creates reliable protection of walls from weather influences;

- facing out of the porcelain stoneware looks and gives the building of solidity and respectability, allows to align the depressions and bulges of the walls without performing plastering works;

- the use of thermal insulation materials in the design of the ventilated facade makes it possible to effectively insulate the building, which will save money to heat the rooms in winter, and in the summer there will be a cooler;

- ease of installation - the installation technology of the ventilated facade of a porcelain stoneware allows you to carry out work in any season, since it does not need to use special building mixtures and solutions, the installation is fully carried out with the help of mechanical fasteners, due to which its speed increases significantly;

- thanks to the air layer between the main and auxiliary walls, it is possible to avoid the accumulation of dampness and the appearance of condensate;

- facing facing (porcelain stoneware and air layers between the walls) creates an effective soundproofing of the building;

- fire safety - applied materials are not combustible;

- high performance - this facade is distinguished by strength and durability, does not fade, does not require cosmetic repairs.

The device of the ventilated facade of porcelain stoneware

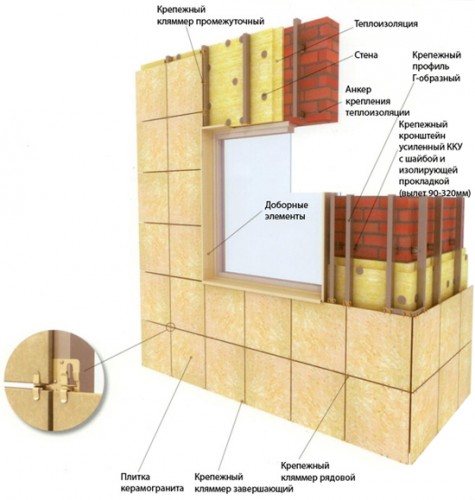

The ventilated facade of porcelain stoneware consists of the following components:

- brackets attached to the main wall with dowels and anchors;

- horizontal, as well as the main and auxiliary vertical profile manufactured from corrosion resistant metals (aluminum, steel and alloyed alloys);

- the layer of insulation that protects the wall from temperature fluctuations to avoid deformation processes. The use of thermal insulation materials in the design of the ventilated facade significantly increases the soundproofing of the building (by about twice);

- elements of fasteners - klimmers, corners, sealing tapes;

- porcelain tile.

As a support for the design of the ventilated facade of a porcelain stoneware, carrier walls of the building are served. The subsenight system consisting of brackets, supporting profiles and special fasteners, serves to mount the porcelain tile and the thermal insulating layer to the main walls of the building.

The use of vapor-permeable materials - a special film that prevents moisture condensation on thermal insulation contributes to the effective removal of dampness from the design of the outside.

Installation technology of ventilated facade of porcelain stoneware

Organization of preliminary work

The procedure for conducting organizational and preparatory work approved legislatively, they must be carried out to ensure the safety of workers and tenants.

When organizing work on the installation of a ventilated facade of porcelain stoneware:

- specify the borders of the danger zone - 3 meters from the walls of the building;

- on the specified area to prepare the necessary materials and equipment, as well as determine the place for assembly work. If mineral wool is used as a heater, the building pallets should be prepared in order to avoid absorbing moisture from the Earth;

- in the case of difficult weather conditions (strong wind or low temperatures), installation works should be postponed.

Stages of installation of ventilated facades

The following stages of assembly work can be distinguished:

- It is necessary to take a working draft of the ventilated facade and make a thorough examination of the building using a level or a plumb to identify deviations horizontally and vertical, after which to mark changes in the drawings to recalculate the additional height and, accordingly, the material consumption. It is recommended to make on paper a schematic layout of tiles on the wall. The calculation of the number of plates of porcelain stoneware is made based on the total area of \u200b\u200bthe walls, given the seams between the tiles, as well as the distance to the temperature expansion of the materials.

- Performing markup for fixing brackets - applied according to the construction project. First, the lower horizontal lines are placed, as well as vertical side. Next, using the roulette and laser level, the locations of the brackets are marked.

- According to the markup using special plastic anchors (with steel or polyamide cores), mounted brackets:

- using the perforator, holes are drilled in the walls;

- paronite gaskets are stacked in them;

- the carrier elements are made (screwdrivers are screwed into anchors with a screwdriver).

It is important to observe the side of the bend according to the project so that the vertical axis subsequently has shifted. When mounting the brackets, it is necessary to put the thermor spinning plate from the paronite to the wall. Fixing fixation is carried out using aluminum washers. Anchor hat in order to avoid corrosion paint.

- After fixing the brackets, laying the insulation. For hermetic thermal insulation, a windproof film is used - it takes that its layers overlap each other by no less than 10 cm. The necessary form of the insulation can be given with scissors or a knife. Installation of the insulation begins with the bottom row, the mount is carried out on the base or profile, and then the insulation plates are attached to each other, close to each other in the chess. Between the facing and insulation should be an air layer from 50 mm.

- Next, you need to install vertical guide profiles:

- the profiles are inserted into the removal of the support brackets and are fixed using rivets. It is necessary to provide a temperature expansion of the material - to leave the fasteners of the clearances;

- according to the requirements of fire safety, it is necessary to establish fire cutoffs.

- Installation of veneers of the ventilated facade is as follows:

- installation of facade cassettes - assembly and fastening to the profiles of curvators;

- mounting facing porcelain tiles.

Facing the facade of the building with a porcelain tile can be carried out in two ways:

- installation with visible seams - with the help of fasteners - screws, rivets, curvators. In the ventilated facade of a porcelain tile, the tile is attached to the profile, painted for maximum imperceptibility of seams in tile tone;

- in this case, the tile is attached to the "invisible" method from the inside. Mechanical methods involve the fastening of the tile from the inside of the facade with dowels or pins. For a small tile (60x60 and less), the method of gluing a cladding material with a special adhesive to a vertical profile is used (in this case, the tile can be dismantled only by breaking). There is also a combined fastening method, combining the mechanical fastening of the facing tile at two points and the use of glue.

The seamless fastening costs more expensive, so sometimes the bottom layer of the facing is performed using the "invisible fastening", and for the upper floors of the building, the building is carried out with the help of visible seams - such a trick will reduce costs.