How to cut drywall Useful advice

Those who knew not one repair, in one voice, claim that there is nothing easier than cutting drywall. However, even such a simple task is able to put a newcomer builder in a dead end. The article will tell about how to work properly with the material and try to anticipate all the questions of those who hit the hands of Hypzarton for the first time.

Content

Tools for cutting plasterboard

Specialized publications for builders are recommended to use tools that cost considerable money and first will be useful to customers who work to order. We will talk about the priests that will find at home from any man.

Roulette, line, simple pencil

Please note that the mark on the plasterboard sheet is recommended to do just a simple pencil. Traces left by a marker or a ballpoint handle will subsequently not hide even the most thorough putty.

Construction knife

It can replace the usual stationery knife for paper. True, the construction knife with a replaceable bilateral blade is more convenient to cut more dense materials. This tool is undoubtedly easy to work. He might will cut a paper layer of GLC and with the basis to cope in two bills. However, it will be necessary to tinker to cut off a smooth neat sheet. Therefore, first diameters with a simple pencil, the necessary lines, make cuts and only then, when the perimeter of the part is ready, cut a drywall. The edge of the cut part of GLC will have small jar - they will disappear without a trace if "walk" on them emery.

Hacksaw

We need a tool for metal work. It is characterized by a thinner blade, which neatly and, most importantly, almost without dust will cut a sheet without dust without deforming its edge. If you stopped your choice on the hacksaw, keep in mind that it is impossible to work on weight, otherwise spoil the material. Put the sheet of GLC on a stable support, then on a predetermined line of sawing dimly and is not in a hurry so as not to get back.

Electropolitanzik

You will not have any difficulties if you get high-quality tool caps, it is desirable for metal work. They are distinguished by a smaller tooth, which will leave some chipping on the sheet of the plasterboard sheet. These tools are easy to cut rounded items.

Planchogov for the removal of the champers and the ridgebar

These tools will be needed at the final stage of working with GLC, when it will be necessary to give a neat appearance to its edges.

Good to know - Circular saw with plasterboard do not work. The tool produces a huge amount of dust that will be very closed not only the work room, but also your respiratory organs.

Cutting plasterboard at home

In a straight line

With this type of cutting, the standard sheet of plasterboard give the desired size. Put the source on a stable horizontal surface. After the desired size of the future part, the desired size of the future part is marked from both sides, take a knife for cutting drywall and with a metal line, cut the surface layer of the sheet with a metal line. For convenience, adjust the blade of the knife so that it opposes the handle on such a length that would not greatly exceed the thickness of the GLC.

It is not necessary to abandon the line and cut the material on the battered pencil mark - so inclusions are unlikely to be smooth. Swipe on the working line several times to deepen the cut, then the plasterboard breaks exactly where it is necessary.

Now put the sheet to the rib on the support and slightly knock on the GLC from the opposite side of the side. Sustilly "Run" on the sheet - as a rule, after several blows, the gypsum core breaks through the cutting mark. It remains only to cut the cardboard, which connects two halves of one sheet.

Letter G.

Such a form of material is usually attached if you need to entee a drywall door opening. Measure and outlining the outlines of the future part. Then the short part is cut to the knife, and the long cut with a knife along the proposed scheme above.

Working with GLC, fixed on the wall

Although it is easier to cut the loose drywall that is easier, sometimes there is a need to color and cut off too much after the leaf appeared on the frame. This version of the design is justified by the fact that when the window is trimmed, the window of the window or the angle of the wall, the edge of the plasterboard sheet from aesthetic considerations is limited to accurately overlap on the verge of the surface on which it is fixed. Therefore, a slice-cooling sheet is fixed on the wall somewhat larger than necessary, and only then remove extra centimeters.

Make sure the framework is firmly holding GLC. The question is, from which side of the plasterboard, in this situation it should not arise, because the answer suggests itself - you cut off the top of the leaf, which directly adjacent to the surface of the surface. According to the planned line, spend a tool several times, at the same time, as if rustling "squeezing" unnecessary part. Doodle a sheet on the reverse side. Recall: to give the leaf on the frame the shape of the letter r, cutting the line horizontally, and spill the vertical line with a knife.

Non-standard cutting and curly cutting of drywall

It is often necessary to cut GLCs not in a straight line, but as it requires built-in lighting devices, sockets or their own fantasy in a striving for a multi-level curvilinear ceiling. Working with indirect parts of plasterboard requires a certain skill.

Option 1. To create an ideally round hole in a sheet of plasterboard, you can apply an electric door equipped with a special nozzle-crown of cylindrical shape. There are different on the diameter and applying nozzles, they are also called circular saws. Choose the one that is designed to work with wood, plywood and plasterboard.

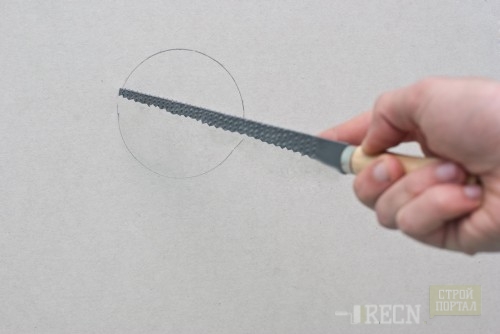

Option 2. If you do not have a circular saw - it does not matter. We work the electric bike: draw a circle of the desired diameter on the sheet of plasterboard, inside which drill the hole. Then insert the tool cloth and, following the markup contour, cut the round hole. Pay attention - working with GLC electrolovik, use a narrow saw with small teeth and do not rush when the sheet is cutting. The result of unhurried work will be a smooth edge of the part. Control the jigsaw slowly, but the tool must work at the maximum speed.

Option 3.If you do not have any of the above tools, the hole in the plasterboard sheet in the extreme case can be done using a special knife for GKL and a hammer. For this:

- apply markup to the working sheet;

- well pressed, shift the marked lines with knife. In this situation, a sufficiently cutting depth in the sheet is very important;

- place the GLK on the surface with the deepening so that this deepening is just under the future hole;

- hit the hammer into the center of the outlined hole so that the sheet core breaks down. Try not to overdo it so that the crack does not go throughout the leaf;

- now shame unnecessary pieces of GLC, cutting off with a knife cardboard from the back of the sheet.

Option 4. The figure cutting of the drywall is the easiest way to carry out an electroll bison, but if you do not have it, it is quite possible to do with it worthy and convenient to replace it - with a hand-hack for GKL. Without hacksaw, you can also cope:

- measure and apply for a sheet of future cuts;

- outline contour Split on relatively straight signts and shift them with a special knife, cutting cardboard and scratching gypsum;

- separated areas take off the same method that the previous cutting of drywall cutting is described.

It is worth noting this technology is effective when cutting large figures. To create elements with a slight radius, use the same hacksaw.

How to handle the part of the GLC after cutting

The edge of the plasterboard sheet, according to which the work tool was just "walked", it looks not quite aesthetic. In order to become smooth and smooth, prepared for the shtlock, army on the Range and remove the chamfer. To this end, you can also use a conventional knife. The chamfer is removed by two thirds of the thickness of the GLC, with an angle of 45 degrees.

How to cut a profile for drywall

To this end, you can use:

- scissors for metal;

- electrol holder with a saw for metal;

- metal hacksaw;

- cutting table or manual machine;

- bulgarian (just in extreme cases - there will be many sparks).

Useful advice

- Cut the plasterboard as possible only on a flat steady surface, otherwise the material will get better and work with it will be more difficult.

- Make sure that the plasterboard sheets are dry moisture can damage the material.

- Large sheets of plasterboard cuts better in several approaches.

- Working with a HCL profile, you can not worry if the sleeve does not work with neat and even - the profile after the installation "hides" under the drywall sheet.

- The framework for GLCs can be shaped even from small parts of the metal profile, the most important thing is on the wall these pieces need to be consolidated "on conscience".

As you can see, there is nothing complicated in working with GLC. To secure the material passed, in particular the question than cutting drywall, offer video: