Waterproofing floor screed with their own hands Insulation,Floors

Waterproofing floor screed is an integral stage of work. It depends on it, how long and comfortable will be the operation of the floor covering. Most believes that waterproofing is needed only on the first floor, in the bathroom or in a private house, but this is not quite so. In this article you will learn why you need to protect the concrete screed from moisture, and what materials will be needed for this.

Content

Why do we need waterproofing

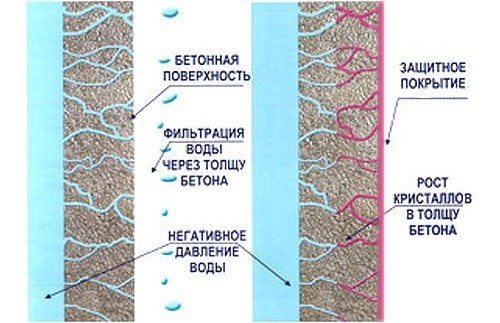

Waterproofing of the floor under the tie is needed not only in rooms with elevated moisture levels. Evaporation accumulate in any room, and since they have a higher temperature, they will inevitably rise up. In apartment buildings, inter-cost floors are made of reinforced concrete plates. Concrete is although it is considered a very durable material, but, nevertheless, has a porous structure that freely misses wet evaporation. They are invisible to the eye and absolutely imperceptible, but they have a destructive effect. So, imagine that the evaporation of moisture from the apartment of the neighbors from the bottom rush up and penetrate into your apartment through the porous structure of the concrete floor. If you make an aligning screed without waterproofing, evaporation slowly, but correctly destroy it. It will take years, but the life of the floor will be significantly reduced. At first, the screed is appreciated by moisture, then it will cover the network of microscopic cracks, and then it will begin to crumble.

This scenario can be prevented by one simple action - to recall the floorproofing of the floor in time before the tie. Since water vapors have an alkaline environment, they react with concrete, destroying it. Your task is to create a barrier between the ferry and the tie.

Types of insulation

The waterproofing material is designed not only to protect the concrete layer of moisture, but also create a more flattened surface and suitable for filling surface. There are several ways to create a protective layer, characterized by the materials used and the desired end result.

Classification of waterproofing screed by type of device:

- Plastering - multi-layer waterproofing coating with a total thickness of up to 2 mm. This method is used for brick and concrete structures, but it is not suitable for the protection of the wooden floor before the tie. Plastering waterproofing can be cold or hot, depending on the mastic used, cololdid cement solution or polymer coatings.

- The painting is a waterproofing coating that is applied to several layers until the thickness is about 2 mm. Bitumen mastic, polymer paints or varnishes are used for coating. Just like plaster, painting protection can be hot or cold. The last form is most popular due to its effectiveness and simplicity of application. For it, the epoxy-rubber mixture is used, and for hot, it is necessary to melt the bitumen, which is pretty difficult in a closed room. Apply material with a wide painting brush.

- Powered - waterproof coating from rolled materials (rubberoid, technonikol, isospan, etc.). Rolls unfold and put stripes with a small adhesive in several layers. Half isolation is universal and suitable for use in concrete and wooden houses. The strips of the material are glued with mastic or bind gas torch (prescribed).

- The impregnating is a protective layer of porous material impregnated with moisture-resistant knitting mixtures. Basically impregnating waterproofing are used in wooden buildings. Bituminous resins, polymer varnishes, a coal pitch or petrolatum appear as binding solutions. Before tie, experts recommend to soak not only the draft floor, but also all wooden floors and poles.

- Lata is the most durable and reliable way of waterproofing screed according to professionals. To create a protective coating, a mixture of bitumen mastic and hot asphalt is used, pouring it into 2-3 layers (the total thickness can be from 10 to 25 mm). To knead the hydrophobic solution, bitumertochitis, foam epoxide, asphalt ceramzite concrete are used. This method is the most expensive and heavy. Not any overlap or foundation will be able to withstand a similar load, so careful preliminary calculations are needed.

- Bending - a waterproofing coating is created from bulk moisture-resistant materials (hydrocarbonate powder, asphaltizol). To obtain truly reliable protection, the waterproofing layer should be about 50 cm, which is tremendously much compared to other methods. However, bothering materials not only protect the screed from moisture, but also create a good thermal insulation pillow. This method is most often used before filling the screed in the basement or on the ground floor.

- Mounted - Protective coating of a collection type, attached to the rough semi mounting bundles. The metal or plastic plate or a profiled belt can be used as constituent elements.

- Injection - floor protection method to the coupler, wherein the hydrophobic liquid material fills all mikrotreschinki rough coating. Basically it is used for the restoration and strengthening of old concrete floors.

waterproofing materials

Waterproofing materials for the floor in the construction market is many times more than the above-described technology. They must choose, starting from the ultimate goal, the operating conditions in the room repaired, personal experience and financial capacity. For example, the deposited insulation gives excellent results and is suitable even for wet areas, but it needs the gas burner assembly.

Consider the most popular hydrophobic materials used in private construction:

- Liquid glass is a relatively new material to create an impregnating (injection) waterproofing of porous surfaces. Perfect for the protection of concrete floors, wooden floors and brick walls. The principle of operation is very simple and effective: the liquid glass is applied to the surface, through the pores it penetrates deep into, where it is immediately crystallized (freezing), filling itself all empties inside the material. For a better effect, it is recommended to apply in 2-3 layers, waiting for the complete drying of each (the crystallization time is indicated on the package).

- Technonol - a series of rolled waterproofing materials used for gender, walls, roofs and other surfaces. In contrast to the ordinary rubberoid or construction polyethylene, technonol rolled materials have a multi-layer structure, and therefore it is better to protect the screed from moisture.

- Izospan is another novelty in the construction market. The material fell in love with builders by the fact that it is very convenient in circulation - it is also easy to lay as polyethylene, but it does not break, does not express and longer serves. There are several types of isospan, excellent performance, for example, specifically for warm floors.

- Polyethylene film is the easiest and cheapest way to make waterproofing the floor screed with your own hands. Most often, the film is used for wooden floors, laying it on the draft floor and missing the joints with bitumen mastic. But the PVC film has a lot of flaws compared to the materials described above: it is taking it, it is torn, it serves a long time.

The cost of waterproofing floor screed depends on the selected material and work volumes. If we are talking about repairing in the living room or, let's say, in the bedroom on the second floor of a wooden house, you can save and use an inexpensive film or liquid glass. But to protect the basement, the basement or floor in the bathroom should not save.

Technology Waterproofing Screws

In this chapter, we will tell you in detail how to perform waterproofing work before the pouring of the screed with their own hands. Depending on the material selected, the technology will differ. We stopped only on those who can even master the newcomer without much difficulty.

Rolled materials

Rolled materials are the most common and relatively inexpensive. It is convenient to work with them and it is possible to obtain reliable protection of the floor for many years. In rooms with elevated moisture levels, it is better to use TechnoNikol, and a cheaper regteroid is suitable for ordinary rooms.

Technology laying rolled waterproofing:

- Along the perimeter of the room along the lower edge of the walls, attach the damper tape to compensate for the expansion of the concrete screed due to temperature differences. If this is not done, the screed cracks around the edges. Use the adhesive layer or dowel-nails to fix the damper ribbon.

- If necessary, align the base of the floor, falling asleep with its sifted sand or drops are injected with cement mortar.

- If you use polymer waterproofing films, cover the concrete floor to the primer is not needed. To achieve a better effect, experts are advised to pre-process the surface with penetrating waterproofing, and only then lay the film, rubberoid or technonol.

- If you use a regular runner before sticking it to mastic, cover the floor by primer for better clutch of materials.

- Feline the strips of the material with a small adhesive on each other at 10 cm, on the walls - at 15-20 cm (after filling the screed of excess material it will be necessary to trim). Enclose the ruberoid to the base and wake the joints of the mastic.

- If you work with waterproofing, for example, glass trap, you will need a gas burner. But the rest of the stacking principle is the same.

Depending on the material selected, the number of protective coating layers varies. So, for the rubberoid, you must at least 2 layers, and one is enough for the weed insulation. The top layer should go perpendicular to the bottom so that the joints do not converge. When the screed dry, cut the insulation sticking along the walls with a floor and proceed to laying the finish coating.

Foolish waterproofing

The coating waterproofing is a healthy competition with rolled materials, since it is also very easy to use. You will need only a painting brush for work. However, in this case, special attention should be paid to preparatory work - on the basis there should be no dust, dirt, protruding acute particles, oil and paint stains. All this may worsen the protective layer. Chemically active substances, for example, stains from the spilled solvent are especially dangerous.

How to work with cold bitumen coating waterproofing:

- Clean the surface of the draft floor and process it with a primer for the selected mastic. Specialists recommend using the PRIM and mastic of one manufacturer. Apply a primer into one layer, thoroughly missing all the plots. Special attention is paid to the shakes of the floor with walls and sections around the pipes.

- After drying the primer (usually about 2 h), you can apply mastic. To do this, use a painting brush or roller. If you work roller, prepare a narrow brush for processing hard-to-reach places.

- When the first layer of mastic grabs, apply the second, moving the roller (brush) perpendicular to the lower stacks.

- Full drying of the waterproofing coating in 2-3 days. It is not recommended to fill the screed to this point.

Useful advice: If you make a strengthening of the screed by reinforcement, install it on plastic guides so that the metal does not contact with waterproofing, otherwise it can damage it.

Bulk mixes

And the last most popular way is to use bulk mixtures. The price of the waterproofing of the floor screed in this case will be slightly higher compared to the methods described above, but the coating will be more reliable, durable and smooth. To work, you will need a polymer-cemental leveling solution. It simultaneously fills the microcracks and pores of the rough base and gives a smooth durable coating suitable for laying laminate, linoleum, tiles, etc.

Stages of work:

- Clean the floor from dirt, dust, stains.

- Cracks and large gaps grease cement mortar.

- Apply penetrating primer to provide better adhesion with a bulk mixture.

- Fill the cement-polymer solution with a smooth layer with a thickness of up to 20 mm. If the alignment needs a thicker layer, pour into two stages, waiting for the drying of the first layer.

- Come on the surface with a needle roller to release air bubbles and increase the strength of the base.

Useful: cement-polymer mixtures are sold in bags of 25 kg. Regardless of the manufacturer, the flow rate is approximately the same - about 1.5 kg / m² per 1 mm thickness.

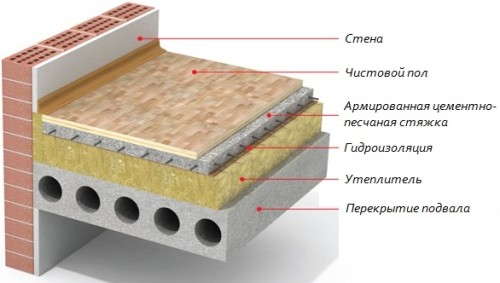

To get the most reliable waterproofing of the floor before the tie, it is better to combine two methods, for example, impregnating waterproofing with a coating or roller. If you work on the first floor of the house without a basement, do not forget to lay the insulation (in the draft floor to put waterproofing, insulation, again waterproofing, reinforcement and tie). In rooms with elevated moisture levels, you can make double waterproofing - to the pouring of the screed and after it is frozen.

Finally, we suggest watch a training video on the floorproofing of the floor tie: