Heat insulating plates: description, choice, application Insulation

In the desire to save the heat of their home and reduce energy consumption for heating, people increasingly began to wonder how to apply the insulation for the walls so that the temperature holds and was durable.

Content

Requirements for thermal insulation plates

Solve the issue of maintaining heat in the house will help you heat-insulating plates, which are used for insulation, both facades of houses and roofs, floors and basements.

The important characteristics of good thermal insulation plates are low thermal conductivity, low average density and high porosity.

The main properties of thermal insulation plates can be called:

- low thermal conductivity and vapor permeability indicators;

- high strength;

- do not flamm;

- resistance to decomposition and durability;

- ecology material.

The first requirement for thermal insulation plates is the preservation of heat. All types of thermal insulation materials are cope with this in varying degrees. When studying the properties of thermal insulation, it is necessary to pay attention to its resistance to temperatures, vapor permeability, air permeability, for resistance to chemicals, that is, to the insulation reaction when the solvent, oils and other organic substances enter. An important point in the requirements of the requirements is the environmental friendliness of thermal insulation.

It is necessary to store thermal insulation plates in a dry and spacious room so that they do not drink moisture and have not been exposed to deformities. When fastening the heat insulating plates, it is necessary that they firmly fit together and surfaces without leaving gaps and empty seats.

Basalt heat insulating plates

Basalt thermal insulation plates are most widely used in the energy industry and construction.

The basis for the manufacture of basalt thermal insulation plates is a fiber from the mining and rocky breed of basalt. The stove data is recommended for use as first-class material, most of their environmental friendliness and a high degree of heat conservation. At the same time, they do not distinguish the smell and harmful vapors, and also meet the requirements of fire safety. This material is able to withstand the temperature from up to +700 degrees.

The region of their use is the thermal insulation of the walls, roof, overlap, and sound insulation. Basalt thermal insulation plates Non-flavored, have a low thermal conductivity, a long service life and, that a lot is important, an acceptable price.

Advantages:

- thermal insulation plates based on basalt fiber perfectly withstand high temperatures;

- durability, their service life is more than 50 years. In this case, the properties of the plates are saved;

- differ in good sound insulation, resistant to chemicals and to moisture;

- resistant when changed temperature;

- withstand heavy loads. When deforming in 10%, basalt insulation fixes the limits of compression strength up to 80 kPa.

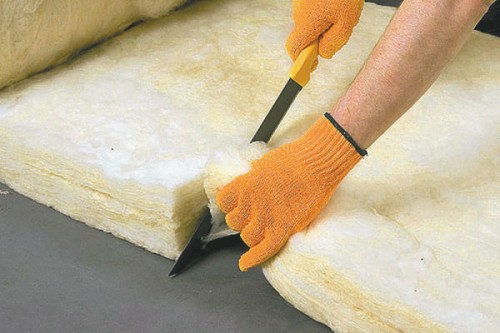

Mineral wool insulating plates

Very often, builders are used to preserve heat in the premises of the builders from mineral wool insulating plates.

Just like basalt, they are resistant to hot temperatures, and wool will start melting after a two-hour effect of temperature, above 1000 degrees. Among the characteristics of mineral wool slabs, it is possible to note the chemical influence resistance, as well as a high record permeability. Due to this couple, the moisture indoors easily evaporates well. Plate data is recommended to apply high humidity.

At the slab, which is based on mineral wool, not high strength and low hardness. By weight, they are heavier than, for example, polystyrene foam plates.

When the facades are insulated, two types of mineral wool insulation plates are used:

- Plates that have chaotically arranged fibers. Their tensile strength is 10 kPa, length - up to 1200 mm, width - up to 600 mm.

- In the slabs, with fibers located perpendicularly walls, the tensile strength is 80 kPa, size is 1200 mm per 200 mm.

Advantages:

- resistant to positive temperatures;

- high vapor permeability and sound insulation;

- such plates are made of weakly aggravated materials;

- resistant to chemicals;

- without efforts, change the form suitable for the type of wall walls.

Disadvantages:

- large weight: one square meter plate weighs more than 30 kg;

- low rigidity;

- low-strength;

- high price;

- when working, the appearance of irritation on the skin.

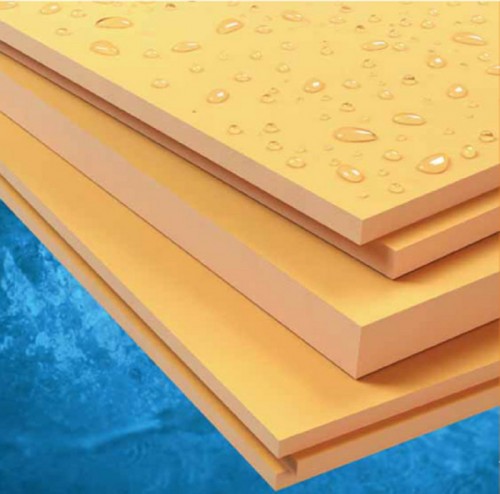

Polystyrene foam insulating plates

The polystyrene thermal insulation plates are made of foam. Unlike mineral wool, their cost is significantly less, but their qualitative indicators are significantly lower. The polystyrene foam plates can be collapsed with a long-term exposure of the temperature of more than 80 degrees.

These stoves are used in thermal insulation of private houses. They are easy to transport, as the polystyrene foam is lightweight. And it's easier to work with him.

Advantages:

- polystyrene foam plates light by weight;

- the plates of thermal insulation of polystyrene foam have a thickness of from 20 to 200 mm;

- durable: On the gap - 80kpa, on compression - 130kpa.;

- the cheapest of all kinds of thermal insulation plates;

- convenient in the mount;

- gigroscopic and resistant to moisture.

Disadvantages:

- easily flammable;

- weak soundproof properties;

- no solvent resistance;

- suitable only for the insulation of residential private houses.

Perlito-cement thermal insulation plates

During the construction and installation of industrial structures, pelito-cement thermal insulation plates are often used. They are made on the basis of perlite, which is mixed with cement and asbestos pulp.

The heat-insulating plates are peerly cement are difficult and suitable for fire protection of wooden structures, for thermal insulation of residential buildings and industrial structures. Sizes of plates - 500x500x50.

The stove strength during bending is 2.5 kgf / cm2, and the density is 320 ± 25 kg / m3.

Advantages:

- material is resistant to mechanical effects;

- high sound and thermal insulation abilities;

- resistant to atmospheric effects;

- environmentally safe;

- resistant to chemical exposure;

- non-toxic.

Disadvantages:

- complex transportation due to the fragility of the material.

Fiberglass thermal insulation plates

The heat-insulating plates from fiberglass are made on the basis of the recycling of the glass industry, often used for thermal insulation of uneven walls, ceilings, hinged facades, partitions and basements.

Due to the fact that fiberglass plates have elevated properties of elasticity and compressibility, they are convenient for thermal insulation in hard-to-reach places. This property features fiberglass plates from mineral plates. Transportation of such slabs is possible in rolls. They are chemically stable and excellent soundproofers. And if all the rules were complied with the installation, it is environmentally friendly. When combustion does not emit toxic substances.

Advantages:

- low thermal conductivity;

- chemical stability;

- not hygroscopicity;

- elasticity and compressibility. Due to which, after compression, thermal insulation plates made of fiberglass are capable of restoring to its original position.

Disadvantages:

- absorption of moisture. But this quality does not worsen the properties of fiberglass to hold heat.

Selection of heat insulating plates

If, when choosing heat-insulating plates, the task is to preserve the heat in the house as much as possible, then the important property of a good material is the low thermal conductivity (so that in the winter the room slowly cooled, and in the summer, on the contrary - slowly heated), low water absorption level (as the wet insulation is better in heat). The heat insulation plates must be fireproof and able to withstand high temperatures. It is very important when choosing heat-insulating plates to pay attention to the environmental friendliness of materials from which insulation are manufactured.

For the most part, when performing construction work, in particular, when insulating facades, heat-insulating plates from mineral wool are used.

In second place to use basalt heat-insulating plates. The insulation from basalt is considered a durable, so-flammable material with good thermal insulation properties. Also, the basalt insulation retains its sizes and properties during the entire service life.

Fiberglass insulation, unlike all of the above, is manufactured in rolls. When strengthening this insulation, it is necessary to comply with all the rules, since the glass gamble is considered not environmentally friendly. When the framework of the frames, it is recommended to use heat-insulating plates with an insulation density up to 20 kg / m3.

Often, polystyrene foam insulation are used for insulation of frames. For some indicators, these insulation exceed the plates from mineral wool. They have low thermal conductivity and high compressive strength. You can buy heat insulating plates at a given price, but do not forget that the quality directly depends on the price. Cheap material can absorb moisture, which gradually destroys the same material.

As construction practice shows, the greatest demand in the building materials market belongs to basalt insulation, which are perfect for the insulation of frames of buildings, partitions, basements, and so on.

But in any case, choosing heat-insulating plates follows from their characteristics and the premises that need to be done warmer.