Laminated formwork plywood. Features of choice and characteristics Building materials

Construction people know that the quality and reliability of the foundation largely depends on what material the formwork was made. In addition to reliability, the appearance plays a considerable role, so the design is properly built from a good material is almost half of the success.

Content

Laminated formwork plywood: its advantages

Recently, during the construction of private houses and the construction of overlapping in high-rise buildings, laminated phaneer is increasingly used. Her attractiveness for construction professionals is due to the following factors:

- the material is very durable, it does not cut it and does not pull when the cement mixture begins to stick;

- the fixation step is quite wide: the distance between the backups is 600-1000 mm;

- after soaring the cement mixture in the plywood formwork, the surface of the product becomes smooth and smooth, it does not need additional leveling work;

- laminated Phaneur is easy to use in all conditions and planes;

- the process of assembling and disassembling plywood formwork is easy and occurs pretty quickly;

- after the plywood in the formwork served his time, it is used to arrange draft floors, both in residential and in economic premises;

- the formwork from this material is used multiple times - 50-100 times.

Laminated plywood formwork is often spoken. Sometimes it happens that it is possible to use the product much less than once promised by the manufacturer. Even high cost is not always a guarantee that the quality will be at a decent level. Therefore, it is best to contact well-known firms that have long existed in the market.

Laminated formwork plywood: Price

If the material is necessary for use in professional construction, it is better to choose Bakelite Phaneur. Manufacturers claim that the buyer will be able to use the formwork from it until hundreds of times, therefore, despite the high cost, to acquire such a material is beneficial.

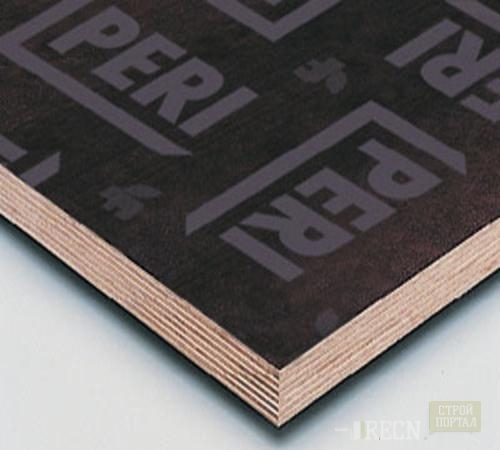

If the plywood is needed for one-time use, for example, during an independent building of a private house, it is possible to do cheaper more cheap species. The most chassis thickness of plywood for formwork is 21 and 18 mm. It consists of several layers and has water-repellent properties.

Advantages of plywood in front of the board:

- plywood laminated for formwork, the dimensions of which are 1220x2440 mm, is more suitable for creating a smooth and smooth surface than a board;

- the board, in contrast to moisture-resistant plywood, it can easily wake;

- when the plywood in the formwork serves his time, it will get better black floors from it than from the board, which is plus to everything else and does not have sound insulation properties.

Secrets of competent formwork and plywood care

To get high-quality material, it is necessary to comply with some rules:

1. The bars of fastenings are strictly fixed in a strictly vertical position with the help level.

2. The phaneer is fixed on the supports with self-draws, both with external and inner side. At the same time, inside it is very hard and inconvenient. In addition, if the design has to be disassembled, it will have to be removed completely due to the impossibility of accessing the inner fasteners.

3. It is possible to achieve acceptable stiffness by making a 1-meter gap between spacers.

4. Working with plywood you should always remember that despite the strength of this material, you should not expose it to gross mechanical exposure, drop, throw, damaging the protective coating.

What is the coating of laminated plywood

Lamination of the material is very important. This coating is at times boosts such qualities as:

- incompetence of moisture;

- wear resistance;

- density;

- resistance to physical influences.

For lamination, the following compositions are used:

- Melamine. It includes pressed melamine-formaldehyde resins. This substance is included in the group of aminoplasts and creates a durable water repellent coating on the surface of plywood.

- Phenol. It is part of the composition of some organic resins used in the manufacture of plywood. True, this option has a smaller moisture resistance than the previous one.

- Polyvinyl chloride or PVC. This material is very popular, because it has excellent technological characteristics along with low chemical activity. PVC is successfully applied in a variety of spheres, including for the release of laminated plywood.

Plywood Care for Formwork

Buy laminated phaneer for formwork is a floor of the case, you still need to competently care and take care of it. Only then will she last long.

The formwork comes into contact with concrete, and it contains various chemical elements, as well as abrasive particles that represent a greater danger to plywood. They often damage her outer layer, and it ends with the imminent destruction of the inner veneer. That is why it is so important to be extremely neat when assembling and disassembling a formwork design, and to clean its surface in a timely manner. It is necessary to do this every time, after the formwork was used, otherwise the service life will be significantly reduced.

But cleaning is not all. Ideally, special water repellent substances should be applied to the phanee, which increase the resistance to the action of moisture and minimize friction.

In addition to the above plywood requires careful circulation. It can not be chosen on the ground, you need to neatly put, while watching the surface to be smooth, without protruding stones and sticks.

Manufacturers of laminated plywood

To date, the main suppliers of laminated plywood are Russia and China.

Chinese products are used to build monolithic buildings. It is considered more profitable for construction, in which the formwork is applied. Plywood from China appeared on our market for a long time and during this time managed to gain popularity, both among professional builders and among homemade craftsmen.

Russian laminated plywood is no less popular. It is considered better and durable, but also more expensive.

The Chinese material consists of a smaller number of veneer sheets, which are also relaxing sometimes. Buying such a material former in use at all is not worth it, because it is unlikely to last long. In this case, it will have to make unforeseen spending on the new Phaneur and the budget scheduled for construction, will be exceeded.

More expensive Russian plywood serves longer and in the end pays off with more than. It causes a protective film that makes mechanical and chemical impact harmless.

In the case of the purchase of used material, you should ask the seller to present checks, invalid or other documents confirming that the goods were purchased in a solid organization that does not trade low-quality lots. Remember always that the miser pays twice. It is better to fork out for a good purchase, which will last for many years than to save, and then spend repaid to replace the thing prematurely.