Acrylic sealants: characteristics and application Building materials

All the many advantages of silicone sealants does not make it an ideal sealant. In some cases, tasks better cope acrylic sealant. What makes means what it is and how it differs from its silicone "brother", tells our article.

Content

Depending on how it becomes part after applying all the sealing means are divided into three groups:

- Non-solidifying compositions - it is in the form of sealing mastic, the most primitive of them - ordinary clay.

- The hydraulic compositions - this silicone materials which harden by a chemical reaction (curing process).

- Drying compositions - such sealants become hard due to the gradual evaporation of the liquid.

This group includes acrylic sealants, created on the basis of polymers. After application of sufficient material one day to dry. One-component acrylic sealant is ready for use after opening the package. Other types of sealants are two-component: before using their components need to pre-mix.

Acrylic Sealant: composition

Organic material is polymethylmethacrylate original frame in the manufacture of acrylic sealants: it is included in the composition as an aqueous dispersion. Today PMMA is considered one of the strongest plastics. Besides it in the creation of an acrylic material are:

- thickeners;

- fillers;

- ammonia;

- plasticizers;

- defoamers;

- Pav and antiseptic additives.

Acrylic sealant: characteristics

Acrylic material for a long time remains elastic, adapts to frequent vibrations, moreover, such a sealant is easy to paint and shuffle. The tool is ideal for sealing small holes and cracks - acrylic is just poured inside and wait for it to dry.

Experts recommend adjusting problem areas with acrylic sealant solely indoors. In "room" conditions, the material copes well with deformation, which occurs when the moisture differences and temperature fluctuations. But the open air does not actually affect the acrylic: minus temperature will make the material too solid. However, here the opinions of competent people are diverged.

Sealants on the basis of acrylic when tensile, the so-called material memory is stored - this means that after applying, the tool tries to regain the original appearance. For the characteristic of the quality of the material, the concept of the limit value of the elongation is used at maximum voltage. Stretching the sealant above this limit point makes its deformation irreversible. That is, the more this value, the better properties have the material. The amplitude of the displacement when using the sealant should not be more than 10% of the maximum stretching. In this case, acrylic can be considered sufficiently elastic to perform work outdoors. Acrylic frost-resistant sealant, as a rule, has less rigidity than those materials that are used to work indoors.

Optimal temperature conditions for successful use are the range from -20 ° C to + 70 ° C. Then an acrylic sealant for external work will demonstrate all its positive qualities in full. The tool will withstand not one cycle of freezing and thawing, keeping the seam holistic.

The classic material has a white or transparent color, but if necessary, find a colored acrylic sealant will not be difficult. Most often on the shelves of building stores, you can find hermetic acrylic tools with a tint of wood title: Cherry, Oak, Pine, Mahagon. Thanks to the impressive color scheme and the capabilities of the tinting of many types of acrylic seams can be made almost indistinguishable from the color of those parts that it connects.

Acrylic sealant: advantages and disadvantages

Correctly using acrylic sealant, you can appreciate all its strengths.

- Price. If we compare the prices of equal volumes of silicone and acrylic, the value of the latter will be one and a half times less.

- Easy choice and use. Unlike silicone funds, the choice of acrylic is not very large, but acrylic sealants are more versatile. When working with material problems, there will be no problems: if necessary, not a hardened material can be washed with water, and the already frozen sealant is easy to cut off with a knife.

- Environmental Safety. The aqueous base of acrylic sealant is free from toxins. When working with it, it is possible not to take additional protection measures, because the tool causes an allergic reaction only in exceptional cases. The material is fireproof - in its composition there are no solvents.

- Universality. Acrylic sealants have high adhesive abilities (the means sticks even to a very porous surface).

- It is possible to restore the finished seam and its coloring.

- Excellent ability to skip steam. Acrylic sealant for windows freely releases couples from the room to the street, without accumulating it in the form of condensate between the seams.

- Quality and durability. High-quality acrylic sealants do not turn yellow over time and do not crumble under the influence of ultraviolet, unlike silicones and mounting foam.

Let's talk now about the shortcomings of this means for sealing. Acrylic sealant "is not friendly" with water, and this feature is explained very simple: it is the basis of an aqueous dispersion that can dissolve. It turns out that it is more reliably using acrylic sealants for seams between the wall and the windowsill, between the wall and the door jammer, in wooden coatings - where the percentage of moisture is minimal or is absent at all.

Nevertheless, on the packs of sealants from acrylic, in addition to the warning "not subject to long-term moisture", you can often see the mark "moisture-resistant". It is necessary to understand this as follows: after complete drying, this material becomes moisture-resistant, that is, dissolving water is not amenable to dissolving. But if the seams from acrylic sealant are in force with water for a long time, all properties of the hermetic means are worse.

It follows from this that the acrylic sealant for the bathroom or shower room is not the best choice. Also, this type of material is not suitable for gluing aquarium, otherwise the finished design is sooner or later will begin to pass water.

Features of the use of acrylic sealants

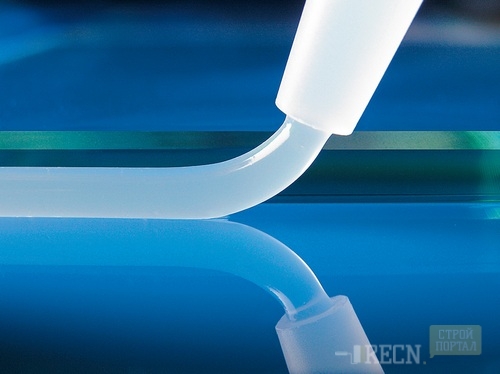

The use of this material does not require special professional skills or experience. All that is needed for the successful use of sealant is an absolutely dry and clean surface that means is applied, squeezing directly from the tube, or with a gun intended for this purpose.

Before the direct application of the material should be paid to the depth of the seam. If it is large enough, the seam is better to fill in the seal or put a special cord there. Such a trick allows you to significantly save the sealant. After applying the hermetic equipment, the working surface is cleaned and degreased.

This material can be used not only as a seal for cracks. For example, an acrylic sealant for the ceiling plinth with confidence can be called a decent alternative to the construction glue. Without it, it is also not to do with the finishing works after installing the cartoons. The place where the baguette will be glued with the help of the sealant, you must first moisten with water so that the seed material is not dry too fast. Then a little acrylic material is applied to the panel and tightly pressed it to the wall, fixing in the desired position.

Acrylic sealant for ceiling tiles - an indispensable means to "hide" gaps between tiles, which appear due to an uneven base. Of course, for this purpose you can use a white silicone sealant, that's just it is inferior to an acrylic analogue in that it is subsequently not amenable to coloring.

Fifteen minutes after the application of the acrylic sealant film surface is tightened. At air temperature + 23 ° C and humidity 50%, the material polymerization process takes 1 day.

Scope of application of acrylic sealants

A mass of acrylic sealant applied to the working surface is easy to adjust, the material fills large cracks and wide slots, and after drying it is not prone to deformation.

The main "field of activity" for the use of acrylic sealants - the boundaries of moving and sedentary connections. With the help of acrylics you can:

- repair cracked furniture;

- restore parquet and wooden floors;

- sealing laminate;

- mount door and window frames;

- installing baseboards;

- eliminate the cracks in the walls and window sills;

- sealing the joints of the pipes and tiles.

Obviously, the scope of this material is rather impressive: the acrylic sealant for the laminate can be completely calmly used to seal the slot between the windowsill and the wall, and the acrylic sealant on the tree is quite suitable for sealing the window frame. Of course, like other materials, acrylic sealants are divided into several types of appointment (for baths, for windows, universal acrylic sealant), but there is no fundamental difference between them.

For human health, acrylic sealants are not dangerous, they can safely use in residential premises, not experiencing that toxic substances fall into the air. In the means of a hardly distinguishable smell, its remnants are easy to launder from the tools at the end of work.

Due to the strength, low thermal conductivity, thermoplasticity and light-resistance of acrylic sealants, they are widely used by the space and aircraft. Today, organic glass, acrylic baths and medical prostheses are manufactured with acrylics.