How to choose glue for aerated concrete blocks Useful advice,Building materials

For the installation of aerated concrete blocks, a specially designed mounting glue is applied. The adhesive substance has high thermal insulating and adhesive properties.

Content

The glue for aerated concrete is made on the basis of cement, polymer additives, mineral fillers and sand. Moreover, each of the components contained in the composition performs its functions: plasticity, strength, resistance to moisture, etc.

Characteristic of glue for aerated concrete blocks

The use of glue carries certain advantages over counterparts. The product has:

- high plasticity;

- moisture resistance;

- frost resistance;

- high degree of adhesion;

- fast setting.

The composition of the adhesive for aerated concrete includes portland cement and high-quality fractional sand. Due to this, the thickness needed for a reliable clutch decreases to 2 mm. Naturally, adhesion is in no way affects. Finally, the glue polyurethane for aerated concrete solidifies without shrinkage, which prevents the appearance of the so-called "Cold Bridges".

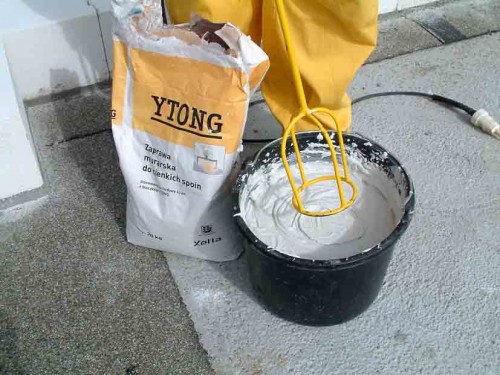

Another distinctive feature is the convenience of cooking and applying the composition. To prepare, it is sufficient to mix the dry concentrate with the liquid according to the proportion indicated on the package. Mix material, as a rule, an electrical drill with a nozzle. In this position, the substance remains suitable for several hours, despite the rapid grasp. The consumption of adhesive for aerated concrete blocks is minimized by the rational use and preparation of small portions.

Main characteristics:

- Moisture resistance - 95%.

- The size of the grain size of the filler is 0.67 mm.

- Exposure time - 15 min.

- Working point of use - + 5 ° C + 25 ° C.

- Block adjustment time - 3 min.

- Drying time - 2 h.

Composition and method of use of glue for aerated concrete blocks

The product includes the following materials and mixtures:

- the main binder is Portland cement;

- sedane washed sand shallow fraction;

- additive modifiers. They hold moisture inside and prevent the formation of cracks under the influence of high temperature;

- polymer additives. They significantly improve adhesion and fill any irregularities of the treated surface.

Special additives that are included in the product made it possible to achieve minimal thermal conductivity.

Mode of application

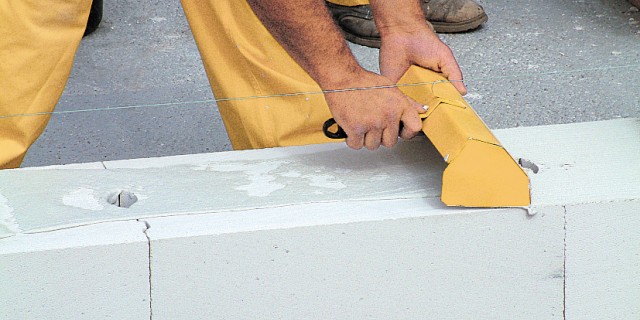

- With the help of a carriage or a toothed spatula, the glue is applied with a thin layer on the moistened clean surface.

- A gas-concrete block is applied and pressed.

- If necessary, it is leveled by tapping with rubber Cyans.

- At high air temperature, it is necessary to cover fresh tarpace or polyethylene.

The calculation of glue on aerated concrete blocks is based on approximately one packaging per 1 m³ of material. This is provided if the layer is 3 mm. However, in practice, consumption is one and a half times higher than the expectations. This fact should be taken into account.

What to buy glue for aerated concrete in winter?

During construction, accompanied by negative temperature indicators, the so-called winter glue comes to help specialists. The product includes antiorrosic substances. However, winter glue has certain limitations for operation. If the thermometer demonstrates a decrease in temperature below -10 ° C, it is reasonable to refuse to reasonably.

With winter construction, the design is additionally protected by tarpaulin. And the masonry process is carried out so that the temperature is to be prepared for the use of the mixture on the threshold 0 ° C. In this case, it is important that the freezing of water does not provoke a deterioration in the performance characteristics of the glue.

Distinctive features of the frost-resistant adhesive composition:

- Grey colour.

- Minimal thermal losses.

- High frost resistance.

- Moisture resistance.

- Ecology.

- Plastic.

- Resistance to natural impacts.

- Preventing the emergence of the so-called "Cold Bridges".

- Operation for internal and external work.

- Antiorrosal additives in the composition.

Experts share recommendations for the use of frost-resistant adhesive compositions:

- Use glue is necessary for half an hour.

- The laying of aerated concrete blocks for glue is not allowed in snow or rain.

- Material for masonry should not be frozen or wet.

- Mixing the solution should be made in the warm room. Moreover, water should be heated to + 60 ° C, and the temperature of the finished mixture is + 10 ° C.

- Keep the packaging is needed in the warm room.

The best manufacturers of glue for aerated concrete

The optimal composition and stunning operational properties has a slice of aerated concrete. The product is designed for use in the premises and outside. It is economical and effective. Turn to the characteristics:

- The maximum grain size of the filler is 0.6 mm.

- Exposure time - 10 min.

- Working point of use - + 5 ° C + 25 ° C.

- Block adjustment time - 10 min.

- Drying time - 4 h.

- Layer thickness - 3 mm.

- The volume of water is about 5 liters per pack.

- Consumption is one package of 25 kg per 1 m³.

- Layer thickness - 3 mm.

No less effective for winter construction glue for agenic azolithon. The moisture-resistant mixture is designed for foam concrete, silicate and aerated concrete blocks. Composition characteristics:

- Consumption is one package of 25 kg per 1 m³.

- Mass humidity - 0.08%.

- The mobility of the adhesive is 5-7 cm.

- Compressive strength - 11.2 kgf / m².

- Bending strength - 4.1 MPa.

- Moisture absorption by weight - 2%.

- Drying time - 2 h.

- Adhesion to the concrete base - 0.4 MPa.

The exact geometric characteristics of the blocks allow you to build perfectly smooth walls in any weather. And with significant savings. For example, adhesive for aerated concrete Aerock is sufficient six times less than the traditional cement-sand solution. What is curious, the price of glue for aerated concrete blocks is only twice as expensive than mixtures of cement and sand.

Features of using glue

Whatever use a mixture for aerated concrete, whether Ceresit glue or the company's products are fastened, you will be a priori. Branded adhesives of well-known manufacturers demonstrate high adhesion, frost resistance, plasticity and other advantages.

Bribes the universality of glue. The mixture is allowed to be used not only when laying aerated concrete blocks, but also when installing bricks, ceramic tiles, foam blocks, putty.

The advantage of similar products in economy and efficiency. For comparison: when using a cement-sand solution, a layer is needed at least 1.5 cm. When used, let's say, the adhesive for aerated concrete, 2 mm will be enough. Breaking savings are obvious. And due to the high adhesion, the wall of the blocks receives monolithic strength.

Finally, we will tell about the nuances of the laying technology:

- Prepare the required amount of glue to work. Otherwise, the solution will lose its elasticity after 2-4 hours.

- The thin layer of the substance dries over 3 minutes.

- After cooking glue, stand it for 15 minutes.

- Mix the dry product with hot water (up to + 60 ° C).

- Work in gloves and clothing with long sleeves.

Conclusion

The market presents a large number of products for gluing fuel-concrete blocks. The choice should be made seriously because the integrity of the entire structure depends on this. We recommend trusting proven manufacturers with impeccable reputation. Such are the company "Solving", "Heresit", "Aerith", "Azolith".