How to put construction blocks Construction

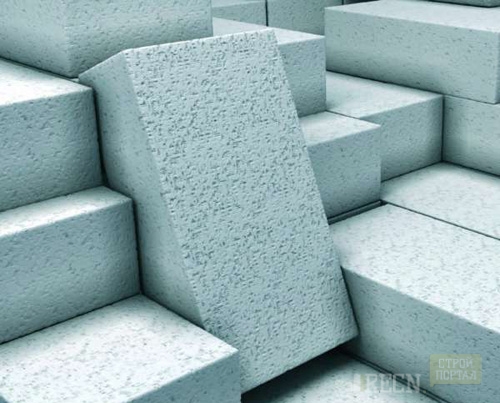

Construction uses various types of blocks. Each species has its own block laying technology.

How to lay foundation blocks?

At the initial stage, the markup is required, which is carried out by laying. Squeeze straight angles according to the foundation pillow and drive into reinforcement. Between "pins" stretch the guides. Work with the foundation blocks manually hard. Hire a faucet, so you finish the first row throughout the day. Before the start of all works, we make a project for which in the future we will work. Laying the foundation blocks, check with the project, from how exactly you put the blocks depends on what the walls and the house will turn out. Minor shortcomings in the process of laying still correct, it is desirable that they are not at all. Too large differences are fraught with the future fault of the walls.

Foundation Blocks Technology Look on video

The technology of laying concrete blocks is the same as when laying, other types of blocks, the difference only in the mixture for clutch. All according to the scheme. Concrete blocks are divided into three types: FBS (integer), FBB (with holes for communications), FBP (P-shaped, hollow).

Concrete blocks are placed on a solution from cement and sand in a 1: 4 ratio. Upon completion of laying between blocks, the distance remains to "lay". Use bricks or fill the "emptiness" concrete. In the second case, the framework of the reinforcement and formwork from the boards is made, then pour concrete.

If the masonry is used as a foundation, then after the second row, the waterproofing is paved and the soil is plugged outside. For an ordinary foundation, enough two-bed heights. If the ground is the role of the ground floor, the minimum height should be at least 4 blocks of 60cm.

Here is one of the types of hollow concrete blocks:

What blocks can be laid on glue?

Special adhesive mixtures are used to masonry foam concrete and aerated concrete blocks. In comparison with the glue solution much cheaper and more convenient to use.

Several types of adhesive mixtures are presented on the market:

- Standard - used in working with ceramzite concrete, foam concrete, aerated concrete blocks.

- For work at low temperatures. They are used in winter when the use of the standard mixture is impossible. The composition has a non-freezing component. So the mixture will dry and not cracking.

- Heat-saving. The consistency and good fastening ability allows the layer of glue subtle, which will limit the seam freezing area.

Among manufacturers are most popular: "Seresit", "Ilmax", "UDK", "Budmayster", etc. The price depends on the manufacturer and the capabilities of the adhesive mixture. Standard cheaper heat saving. Imported, respectively, more expensive "local".

Compare two manufacturer. What is the difference between the mixtures for the gas silicate and the cellular block?

|

|

C.e. resit CT21. |

Budmayster Moore - 160 |

|

Width seam |

1-3 mm |

2-5 mm |

|

Water required by 25 kg of mixture |

7-7.5 L. |

4.5-5.25 L. |

|

Adhesion to the base |

0.5 MPa |

0.3 MPa |

|

Fitness to use diluted mixture |

4 hours |

2 hours |

|

Strength |

8 MPa |

5 MPa |

It can be seen that the mixture "Seresit ST21" has indicators above. As a result, it is more convenient to use and "stronger" in operation. Indicators "Budmayster Moore - 160" meet the requirements. It is necessary to work with it faster or making small knees to avoid frozen. Adhere to the instructions and durability will remain at the highest level.

Foam concrete is made of sand, water cement and foaming agent. It is blocks of bubbles.

Aerated concrete porous blocks from a small amount of cement, quartz sand, gas formation and additional components (ash, slags).

Feno, fuette blocks are placed on a prepared pillow on the guides. As a connector - glue mixture. The first row is placed on waterproofing. First, "put" angular blocks and only then the walls. This will last the correct level angle. The waterproofing layer is paved only on the outer walls. Internal is not isolated.

Some foam blocks have grooves that provide additional adhesion between blocks. Losing glue is needed on the side and on top. In this case, the probability of blowing in places of connection will be reduced to zero. The glue layer is approximately 0.5 cm. Do not make a layer of glue thick, so you will save the material and reduce the probability of blowing on the seams. Take the adhesive mix in the store. You will only remain diluted with water and knead the construction mixer.

When laying, check each block level. All small particles believes and align the grater. In construction stores there are blocks of non-standard length (longer than ordinary). Each next to align the walls on the guides. Watch off the displacement. It should not be less than 10 cm. The discrepancy can lead to cracks and the collapse of the wall.

There is another type of blocks - clay. Made by vibropressive method. Granules of the grainsite "solder", which is even more strengthening the material. Ceramzit blocks can be used to build any walls (external and internal). Minor weight, in comparison with concrete blocks, provides ease of installation. Put them without the help of the crane, do it yourself. Despite the simplicity and lightness, clay blocks are durable and durable in operation. They are easy to handle accessible tools, such as saw or jigsaw. A special adhesive solution is used to fasten blocks.

Is it possible to independently build a house from blocks?

Understanding! To do this, you will need more time, since from creating a project to the final result you will work independently. Of course, you will need tools to work with "delicate" materials.

The first thing that is making is drawn the project and discuss it with a specialist. Sometimes your desires are difficult or impossible to implement. It all depends on the materials that are used in the construction and complexity of the design.

Select blocks for masonry. Read about them or find out people with experience. Each type of blocks has its advantages and disadvantages. Choose yourself that suits you. In accordance with the selection, select the mixture to be used.

What about the foundation? There are also options here. Place the blocks or pour it with cement mortar. When pouring, be sure to use the framework of the reinforcement, it serves as an additional strengthening of the design. Do not forget about reinforcement.

Calculate the number of materials that will be required for construction. When buying, make a small stock "just in case." It happens that blocks require lying.

Construct the foundation with the selected method (blocks or flood). We pave the waterproofing layer. Now proceed to the first row of masonry. All blocks, corners and walls of this row must be perfect. Inaccuracies weave and clean. We establish vertical guides and put the subsequent rows. Observe the offset of the blocks. We put them according to the scheme. Do not diligence with the mixture. You need to make the blocks, and not shuffle. For the formation of window openings, we use overlap, it is desirable from the same material and the same manufacturer as blocks. Manufacturers take into account the load on the opening, so in the manufacture of them are fixed. The reinforcement is made according to the plan. It is needed for "strengthening" walls. All subsequent ranks are put on the same principle. Good luck!