Installation of heating roof and drainage Construction

In winter, housing and communal services and household owners have to do snow cleaning and ice from the roofs. This is a serious problem. Under the severity of a thick layer of snow is possible damage and even collapse of the roof. Iceighted growths pose a safety threat to people. Sossels, falling from the roof, can damage cars parked to the building. Many clean the roofs in the old manner, manually, but it is a heavy, traumatic and ineffective work. Recently, the roof heating systems are increasingly used, which are able to melt the snow and ice and take the talu water away from the foundation of the house. Such devices greatly facilitate the roof care thanks to the automatic mode of operation.

Content

- Causes of roof icing

- Principle of operation of the system "without icicles"

- What tasks and functions perform a heating system of roof and drainage

- Composition of the heating system of the roof and drainage

- Device heating system roofing

- Installation of roof heating. Instruction

- Installation of heating of the roof and drains do it yourself

- Procedure for designing the heating system of the roof and drainage

- How to determine the heating zones

- Selection of heating electrocabel

- Comparative characteristics of resistive and self-regulating cables

- Choosing a control system

- Placing connecting boxes

- Laying of heating electrocabylide

- Calculation of system power

- Power cable tracing

- Select Automatic Control Cabinet Equipment

- Installation of heating roof and drain video

- Installation of heating roof without holes

- Mounting quality check

- Features of the installation of heating various types of roof

- Question price

- Pure roof - pleased the owner!

Causes of roof icing

- Bad thermal insulation roof.

Warm roofing roof, the roof is often subject to the formation of an icy crust. The heated room under the roof contributes to the heating of the roofing coating. On such a roof because of the heat loss even in the cold melts snow. Melt water flows along the roofing skate, on the cold eaves and in the drainage again freezes, turning into icicles. In this case, first of all eliminate the root cause - insulate the roof. With high-quality heat insulation, the heating system will work more economically.

- Seasonal and daily temperature fluctuations.

Even with competent design and construction of the roof, frown appears due to the temperature difference in the day and night, especially in the spring. In the afternoon, the snow melts and flows from the roof in the drain, and at night, with a decrease in air temperature, it freezes, forming huge sleep. Under the severity of ice growths, the drainage system comes into disrepair.

Principle of operation of the system "without icicles"

The effect of modern roof protection systems from the ice is based on heating due to electric cable heat transfer. The heating electrocabolic is laid on the roof, in the gutters, drainage pipes, places of snow accumulation and ice. The cable heating system causes the melting of snow and contributes to the free outflow of melt water from the roof to the ground for some distance from the house.

What tasks and functions perform a heating system of roof and drainage

- Preventing the formation of icicles, clusters and drops of snow masses and ice layers.

- Organization of a normal regular removal of melt water from the roof and drainage.

- Exclusion of blockage and deformations of the drainage system of ice traffic jams.

- Reducing the mechanical load on the roof design.

- Eliminating the problem of manual cleaning of the roof of snow and ice.

- Increased service life of the roof.

- Complete automation of roof heating and the absence of the need to participate in a person in managing the system.

Composition of the heating system of the roof and drainage

- Heating electrocabel

- Fasteners

- Switchboard:

- input three-phase protective machine;

- four-pole contactor;

- protective shutdown device, (30mA);

- single-pole protective machines for each phase;

- warning lamp;

- protective automatic control circuit of the thermostat;

- Distribution network components:

- power supply cable;

- signal cable between thermostat sensors and control unit;

- mounting boxes;

- connecting and end couplings for heating cable.

Device heating system roofing

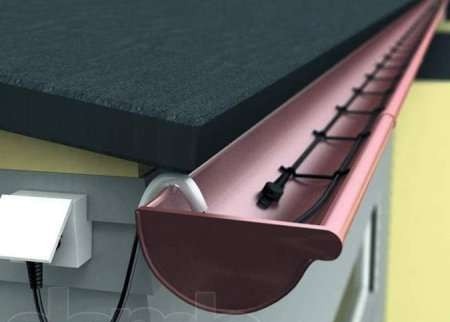

- The heating portion is an electrical cabin, which ensures heating directly roofing and drainage. It is carried out on the outside of rtands, gutters, waterproofs, livnets, trays, drainage pipes. The heating electrical circuit for heating the roof must comply with fire safety requirements, have high mechanical strength, resistance to temperature fluctuations, the effects of sunlight, atmospheric precipitation. The heating cable system for removing ice is quite easy to install, designed for all types of roof, will not dismantle for the summer season, has automatic control.

- The distribution and information part consists of informational and power cables, mounting elements, junction boxes. It performs the function of the distribution and transmission of electrical power supply for the heating part and the exchange of signals between the roof heating control sensors and the control cabinet.

- The control system includes: thermostators, thermal sensors of air, cabinet (shield) of control, start-up and protective devices, adjusting devices. The selection and equipment of the control system is performed in accordance with the power of the roof of the roof. Self-regulating electrocables in the heating systems of drains are capable of working without automatic control. They independently regulate their power under the influence of precipitation and air temperature. However, for efficient and economical operation, the heating system is recommended to use thermostators.

Installation of roof heating. Instruction

Installation of heating of roofing cornices and drains is carried out in the following order:

- The heating sections are checked for compliance with the sizes of the roof heating zones, the sections of the required length are cut, they put clutches, unfold and fastened.

- The electric cabbage in the drainage chutes is fixed by the strips of the mounting ribbon across the gutter. The thicker the mounting tape, the stronger and more durable. For the resistive cable, the tape installation step is 0.25m, for self-regulating - 0.5 m. When fixing the tape on the groove rivets additionally use sealant.

- In the drainage pipes, the electrical circular is fixed using a mounting tape or a heat-shrinkable tube. With a pipe height, more than 6m, the cable is additionally attached to a metal cable with an insulating shell to reduce the carrier load.

- In the opening of the pipe and the funnel, the heating electrocabel is fixed with a mounting ribbon with rivets.

- The mounting of the electrocable to the surface of the roof is performed using the mounting tape and sealant.

- Installation boxes are made, the resistance of the insulation of the heating sections can be measured.

- Thermostat sensors are mounted, signal and power cables are carried out.

- Install the control cabinet.

- Resistance is measured and power and signal cables are squeezed.

- Check the protective shutdown device.

- Regulate the thermostat.

- Perform commissioning work.

Installation of heating of the roof and drains do it yourself

Installing the heating system for the roof is a fairly costly and complex case, but fully justified. Such a system can be collected with your own hands, but the calculation and testing of equipment before launching it is better to charge professionals to ensure the safety of electrical heating.

Procedure for designing the heating system of the roof and drainage

- Determination of roof heating zones.

- Select the electrocable in accordance with the installation conditions.

- Select a control system.

- Determination of the location of the connecting boxes.

- Planning the number and method of laying a heating electrocable.

- Calculation of the power of the system, calculation by phases, the choice of the system of protective automata.

- Selecting the method of fastening power cables.

- Selection of automatic equipment for the cabinet (shield) control.

- Drawing up a complete set of project documentation.

How to determine the heating zones

As zones of heating, places of snow accumulation and ice on the roof are selected. On the formation of the land affects the weather conditions, the material and design of the roof. The optimal is considered a diagram of simultaneous heating of oles, roofing sink and drainage. In order to save, many are laid by cable only on the surface of the roof, erroneously believing that this is enough. In fact, ice congestion is formed very often in the gutters and drain pipes, overlapping the path of melt water.

The quality of the organization of drainage is depends on the right choice of styling of the heating cable. First of all, the heating cable is paved in the sections of the most possible formation of land: gutters, drains pipes, endowes. The total length of the electrocable for the anti-flare system is equal to the total length of compound roofing elements requiring heating.

On the roofs with steep slopes, where there is a danger of avalanche-like ice and snow, the snowstand system is assembled and a zigzag is lacing a warm cable between the roof edge and a snowmaker.

In the absence of such a need, only the electric heating gutters and pipes are limited.

Selection of heating electrocabel

The basis of the heating system of roofing and drainage is a resistive and self-regulating electrocabel with a capacity of 20 to 50W per meter.

- The resistive cable is the usual wire made of metal core and isolation. It has permanent resistance, stable heating temperature and constant power. The resistive cable has a low cost. The principle of operation of the cable is that the metal lived is heated due to internal resistance. Waterproof heating in this way is quite simple, the operation of the system does not differ in difficulty and greater costs. Basically, it is used to heat the extended areas of the roof and drainage. The optimal option is the wiring of a zonal resistive electrocable with a special nichrome heating thread. The routing power of such a cable does not depend on the length, it can even be cut if necessary.

- Self-regulating cable is more technological. It consists of a matrix, insulating shell, braids and an outer shell. The matrix, the heating self-regulating element, changes the resistance and degree of heating depending on the ambient temperature. With increasing air temperature in the cable matrix, the amount of conductive paths decreases, resulting in a power, electricity consumption and self-regulating cable temperature. The power of self-regulating cable is selected depending on the diameter of the drain.

- Mixed cable type. A combined cable system is considered a reasonable compromise for the price and quality ratio. Usually, inexpensive cables of resistive type are used for the roofing part of the system, and self-regulating cables are more suitable for heating drainage gutters and pipes.

Comparative characteristics of resistive and self-regulating cables

Both types of heating cables are able to ensure equally efficient heating of the roof and drainage. However, each of them has its advantages.

Resistive heating cable distinguish:

- Low cost.

- Small starting current.

- Continuous power and good heat transfer. Although in some cases it can become a significant minus, because due to the different need warm, some parts of the roof can overheat, and others do not get enough heating

- Easy installation of the system. The resistive cable is carried out along the grooves and pipes or whining them.

The disadvantages include: increased electricity consumption, design restrictions, a smaller service life compared to self-regulating cable and the likelihood of local overheating in places of rehearse.

Despite the high cost, for heating the roof, experts still prefer to use a self-regulating cable, which is made according to special technology. Due to the unique molecular structure, the self-regulating cable reacts sensitively to atmospheric conditions and independently regulates the heat transfer at each site depending on the temperature regime.

Such cable properties allow the system to work more efficiently and economically.

Advantages of self-regulating heating electrocable:

- Laying the cable in one line. In this case, there is no need to install jumpers, the likelihood of the drains of the drainage system is reduced, the heating wire does not interfere with the timely outflow of water.

- Simple installation. The cable is cut into pieces of any length directly on the object in the process of installation work. This feature, as well as laying the cable in one thread, speeds up the pace of installation and reduces its cost.

- Saving power consumption. In the case of using self-regulating heating cable, electricity savings is more than 50%.

- No risk of overheating and cable brave. The wires of the resistive cable are subject to confusing during a snowy mass from the roof of the building, which leads to their local overheating. In the case of a self-regulating wire, such a problem does not exist, since it is unlikely to confuse when laying in one thread, in addition, the heat transfer of the heating cable is automatically reduced in places of overlapping or contact.

- Reliability. Without mechanical damage, the self-regulating electrocabel provides 100% reliability of the system.

- Durability of operation. Service life of 30 years, which is more than several times than the resistive cable.

Choosing a control system

The control system is capable of significantly reduced electricity consumption depending on weather conditions. The control of the heating system is carried out by the devices of two types:

- The actual thermostat, which includes the heating system in a given temperature range, is usually within -8 +3 degrees.

- Weather storage. In addition to the temperature regime, the meteorological station controls the presence of precipitation on the roof and their melting. The station includes a temperature sensor, a humidity sensor. Some weather stations are equipped simultaneously with precipitation sensor and melting sensor.

When using a conventional thermostat, the user has to independently include the system if there is precipitation and turn off when they are absence. The meteorological station fully automates the system of system operation and even program delays in time.

Placing connecting boxes

Connecting boxes must have access to maintenance. Usually they are mounted on the roof near the heating sections. Installation is also possible on parapets, attic, fences, under the visors.

Laying of heating electrocabylide

Before starting the installation of heating drainage systems and roofs, it is necessary to carefully calculate the cable length and determine its location. The length of the endand, all parts of the system, is measured, the amount and the temporal method of the drain pipes are taken into account. The capacity of 30-60Ws is required by 100-150mm.

Cable electric heating are paved in the following parts of the roof:

- Drainage grooves, elements of gutters, plots around them. The calculation of the length of the heating wire is performed according to the drawing, taking into account the length of the drainage grooves and 10% of the stock. The number of electrocabolic threads depends on the width of the gutter at the calculation of the specific power of 400 W / m. The mount is performed using mounting tape and rivets.

- Correspondures.

- Drain funnels and pipes. For drain pipes, a self-regulating heating electrocabolic should be used. If the resistive cable is set to eliminate the contact between the threads, the dividers with an interval of 25-30 cm apart. The amount of thread depends on the diameter of the drain pipe, material and climatic conditions.

- Drainage trays, waterborgs.

- Nendes and joints of individual parts of the roof. The number of cable threads varies from two to four. The fixation of the cable in the endows is made from below and from above using the mounting tape and cable.

Calculation of system power

When choosing the power of heating cables oriented to regulatory indicators. The rate for the cables of the resistive type is the power18-22 ton on the pattern, for self-regulating - 15-30W per meter. It should be remembered if the drainage system is made of polymer, the power of the cable must be no more than 17W to the pattern of the phenomenon, in order to avoid damage to the drain due to the high heating temperature.

Power cable tracing

Tracing is made according to PUE requirements depending on the conditions of the room in which cables are paved.

Select Automatic Control Cabinet Equipment

The installation of the UDO I utral leakage block is required for reliable protection against shock in extreme situations.

Installation of heating roof and drain video

When installing, the electric cabinel is performed by the most imperceptible and neat way. For the installation of heating wires on the roof, reliable fastening clamps from copper, brass, galvanized steel, which do not require holes are used. They have a variety of shape and firmly fix the cable, resistant to temperature factors and aesthetic.

For heating the roof and drain pipes, heating electrocabels use with a capacity of up to 25W / m. For a roof with a soft coating, plastic drainage pipes and grooves, a cable with a maximum heating capacity is not more than 20W to a tempo "meter.

To obtain the required power on the heating area, the heating wires are packed with a certain fastening step. For fastening, use the mounting tape. Most often, the cable is fixed with a step in 3 cm. Each situation requires an individual approach, therefore, before installing the heating system, it is recommended to calculate power in relation to a particular roof and drainage.

For fastening the heating electrocabyl, the grid with clamps also use. Tightening the clamps should be carefully, otherwise damage, the relief and the occurrence of cable overheating zones will fail the entire heating system.

Laying the electrocable in the gutters and drain pipes.

Gutter - horizontal part of the drainage system. It can be a separate roof element, suspended channel or part of the entire design of the drain and roof. In the groove, the electrical circular is paved in one or more parallel lines. If the roof is "cold", for a standard diameter gutter 100-120mm, there are enough two lines of heating cable with a row power to 50W / m. With a diameter of the gutter, the number of standard lines increase to 4-5. If the roof refers to the category of "warm", then the number of lines are calculated according to the heating power of 100W / m. Fix the heating wire in the groove with special plastic fasteners or stainless mounting ribbon.

The drain pipe is the vertical part of the drainage system. The heat distribution at the top and bottom of the pipe is different. Due to the height difference, strong convection flows arise, causing heat redistribution along the entire length of the drain pipe. As a result, the vertical drainage at the bottom is cooled by the influx of cold air, and the top of the pipe warms up solar rays. In order to compensate, the heat loss and alignment of thermal conductivity additionally insulate the lower part of the pipe by increasing the number of turns of the heating wire.

For additional enhancement of heating of funnels and the outlet sections of the drain pipes, two lines of the cable with a power of 20-30W to the pattern of the temporal meter are made depending on the diameter of the pipes.

To prevent the appearance of a naked on the roofing cornices, use the snake cable laying scheme. Such a scheme involves the wiring of an electrical circular on the edge of the cornice. The zigzag step on rigid roofs is painted in a multiple pattern, and on soft - taking into account the power consumption per square meter (35-40 cm). The height of the "snake" is chosen so as to prevent the cold zones on the heated surface and the formation of ice crust.

The method of fastening the heating electrocable on the vertical drainage is similar to fixing the wires in the gutters. A mounting tape or plastic mounting is also used. When laying a cable in a pipe, it is important to ensure that the cable lines are not intersecting and not in contact with each other. If the length of the drain pipe is more than 2m, then the cable is fixed on a special cable with a plastic shell.

Endow is the inner corner of the roof surface, where the snow and ice is most often assembled and the long time remains in the period of thaw. The greater the snow-ice weight, the greater the possibility of corrosion of roofing material and slide down. In endowes, the roofing electrocabel is paired up and down. The length of laying the heating cable occupies 2/3 of the entire length of the end of the end, and the distance from the beginning of the sink, at least 1m. Estimates of the calculated power are 250-300W per square meter of endanda.

Installation of heating roof without holes

Roof heating systems and mounting methods are constantly being improved. Fasteners for heating cables requiring holes are gradually displaced by new fixtures of more gentle action. For fasteners of heating cables in particularly difficult conditions, a special aluminum tape designed for decades of operation has been developed. The cable is fixed with ribbon along the entire length and tightly pressed to the roof. Due to the good thermal conductivity of aluminum, along the cable, the track is heated with a width of 10-14 cm, much more than with the usual fastener. Installation does not require a single hole. Such fasteners can withstand the snow from the roof and reliably protects the cable from the fesoms along the entire length.

Installation using aluminum tape is performed at a plus temperature. Therefore, such a system is installed before the onset of cold weather.

Mounting quality check

After the installation work, the roof heating system is controlled, namely:

- Measurements of insulation resistance of heating sections, power cable. Measurement results are entered into the protocol.

- Checking with tester of current cables.

- Trial system trial.

- Check the thermal controller, system adjustment.

- The final tuning of the thermal controller is carried out in the cold season.

At the end of commissioning and testing of the heating system of roofing and drainage, executive documentation is drawn up:

- Certificates of all components of the system.

- System passport.

- Control cabinet passport.

- Temperature regulator passport.

- Protocols of insulation resistance measurement protocols.

Features of the installation of heating various types of roof

There are many types of roofing materials and structures, water supply systems. Old houses are generally distinguished by bizarre roofs. Therefore, there are no standard solutions and finished circuits for all roofs. It is often necessary to design a heating system and choose the installation method right in place depending on the situation.

Warm roof

Warm roof is distinguished by insufficient thermal insulation. In this case, additionally pave the heating sections with loops along the roof edge. The width of the loop is 30-50cm, the specific power of the 200-250W system per square meter.

Cold roofing

Cold roof is well insulated, often there is a attic with good ventilation. For such a roof, only heating of waterproofs with a linear power 20-30W per meter is installed, while the power gradually increase to 60-70W in proportion to the length of the drain. All cables necessarily equip the protective device for shutdown.

If the roof drains are not organized enough, then in order to avoid the appearance of the icicles, the roofs of the roof needed additional heating. For this purpose, the heating electrocabel is placed in the form of a loop of 0.5 m wide. Snowproofers are used to protect the cable from mechanical damage.

If the roof without drains

Sometimes there is no drainage system on the roof of the building. In such situations on the roof with a small slope, the "Driping Edge" scheme is mounted, with a large slope - "dripping loop".

Flat roofing

The heating cable is carried out throughout the perimeter of the roof at the bottom of the water flow line (pitch), it is raised into the inner drain funnel at least 40cm. (With internal drainage, i.e. inside the structure), and on external trays - according to the "drip loop" scheme. In areas of the roof adjustment to the parapet, the power of the cable around the receiving tray is 40-80W per square meter. The cable is displayed in the tray itself and laid into the pipe of the drain.

Tiled roof

For fixing the cable, a perforated fastening tape is used. On the new roof, the ribbon is nailed to a wooden base. If the tile is already installed, the tape is supplied to 75mm under the roof layer and is attached to glue.

Question price

The cost of the heating system of the roof, drainage and its installation depends on various factors: structures, material and area of \u200b\u200broofing, the length of the drainage system, the type of heating cable, its power, the type of control system and the rest of the equipment, the manufacturer. The price of self-regulating cable from 240 to 660 rubles, the cost of the resistive cable in the range of 90-150 rubles. The finished kits for heating the roof, drainage gutters and pipes consisting of a self-regulating heating electrocable with a capacity of 30W / m and a supply wire cost from 2290 to 13460 rubles.

The final amount can be called after the design and estimate work. Many companies specializing in the installation of heating systems of the roof, on their sites place prices and are calculated free of charge or indentative cost of equipment and installation.

It is important to take into account not only the costs associated with the installation of the anti-icing system, but subsequent operating costs. For example, the price of a resistive cable is 3-5 times less self-regulating, but more power consumption. Experts will help to give useful tips: what can be saved, and what is not worth it. You can always find the appropriate option and develop an optimal roof heating scheme.

Pure roof - pleased the owner!

Modern equipment for heating the roof greatly simplifies the care of the roof, completely eliminates the appearance of the roof and in the drainage. High-precision sensors and temperature controls operate in standby mode, apply immediately when needed and provide minimal electricity consumption.

All costs associated with the purchase and installation of equipment are not comparable to expensive roof repair. Moreover, when it comes to the safety of people's life, questions about the cost are not discussed.

The system of anti-flare roof times and will ever save homeowners from the cleaning of snow from the roof of a shovel, knocking up icicles and ice blocks and annual roof repair. Clean, strong and reliable roof will serve as a reliable shield from any irregularity, not yet one decade.