How to install a pumping station correctly Useful advice

Private household houses have always lost some apartments in multi-storey buildings. Basically it concerned the communications that were not attended by all buildings. Especially acutely stood a problem with water supply. Modern man struggles with this with a pumping station.

Content

- What you need to know to choose a pumping station

- How the pumping station is arranged

- Pump installation location

- Algorithm Installation of the Pump Station

- How to connect the station to the water supply

- Install or not install a filter for a pumping station

- Common malfunctions in the station and their elimination

These aggregates are sold in the assembled form or are collected independently. Any owner will be able to install a pumping station, you just need to figure out what the unit is, as it works and where it is established.

What you need to know to choose a pumping station

The station needs to choose, pushing away from its needs. Severe two important choice factors:

- technical characteristics of the pumping station,

- distinctive well features.

Specifications include the productivity of the unit. He must give such a water pressure that can cover its consumption and in the house, and at the local territories.

Practice shows that if you need to install a pumping station at the cottage or in a residential building, where 4 people are constantly located, to stop its choice is rationally on the instruments of medium or low power. Such stations are equipped with a 20 liter hydroaccumulator. Station productivity - 2-4 m 3 per hour, pressure 45-55 meters. This is enough to cover the needs of a family of four people.

Evaluating the well, it is necessary to take into account the indicators:

- productivity;

- the size;

- water level with a disconnected pump;

- water level with a pump running;

- a type of filter;

- the width of the pipe.

How the pumping station is arranged

The overall construction of the station is included in itself or a cumulative tank, or a hydroaccumulator. The unit with a cumulative tank is an obsolete version, has many minuses. First, the tank itself is a rather bulky design. Secondly, the water level and its pressure are controlled by the float, which is responsible for the triggering of the sensor when the water level is reduced, the sensor starts the podach. Disadvantages:

- water comes out of the system of gravity, because low pressure is obtained at the output;

- all installation has large dimensions and is not always convenient for accommodation;

- installation of the system is characterized by complexity;

- the cumulative tank must be installed over the station itself, which creates additional problems;

- when the water level sensor breaks, it overflows through the edge of the tank.

Designs with a hydroaccumulator are more reliable and practical. This installation has a relatively small size and easy to install. The system is supplemented with a relay controlling the surrounding air pressure. It compresses it in a water-acupuncture under water pressure. When the pressure level comes to the required limit, the pump automatically turns off and water from the tank is supplied to the crane. As soon as the level drops, the pump starts to work again before establishing the required level.

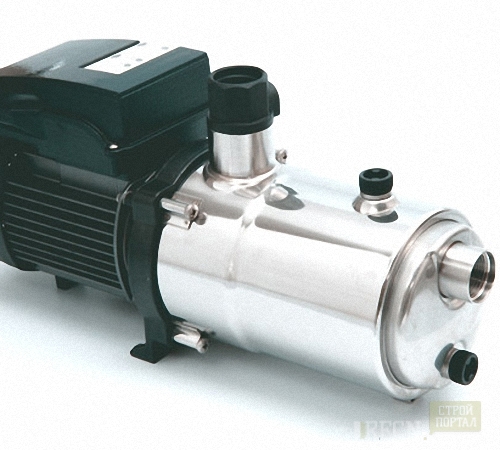

Not only the station of the station differs, but the pump itself. This is the device:

- with built-in ejector;

- with a remote ejector;

- without ejector.

The principle of operation of the ejector - water is supplied from the well due to the discharge created. Modifications data have a slightly large value, but they raise water from 9 m, as classic stations, and even from 20 or 45 m. Ejector pumps are very productive, there is only one drawback - there are many noise when working. This flaw is smoothed by installing the pump with an ejector outside the residential premises.

Pumps with a remote ejector are convenient because the pump itself falls into the place of water intake. Water is supplied to the ejector on the pipe, in which the suction jet is created. According to characteristics and further operation, this design loses pumps with a built-in ejector. If air or sand is present at the water intake site, it leads to a quick pump breakage. Plus the station of such a design - it is simply placed in the house, even at a distance of 20-40 meters from housing.

The pumps without ejectors perform the flow of water a little differently. In such a device there is a complex multi-stage design, which refers to the hydraulic part. The wrongboard station works without noise and consumes less electricity.

These three types of pumps are basic, they are most often used in residential buildings. However, there are still many other varieties of pumps, on the basis of which the pumping station is installed.

Pump installation location

Installing the pump is made in the house or in the caisson. Kesson is an equipped deepening in the ground. The caisson for the pump is protected from moisture, groundwater and low temperatures. Tool it under the line of the soil freezing. This option has a couple of essential flaws. First, it is the need for equipment of this room for the pump. Secondly, it is difficult to insulate it in conditions of harsh climate, and under the action of low temperatures, the pump fails.

The equipment of the pumping station in the house is the most practical option. The optimal placement place is a basement. Only one factor must be taken into account - the probability of flooding basement with groundwater. If during the spring floods it is filled with water, the station must be placed on the elevation, on which it will not be available for moisture. When installing the station should not touch the walls to avoid unnecessary vibrations from its work. The basement also monitors the room temperature at any time of the year to protect the station from frosts.

When choosing a place of installation, the following factors take into account:

- distance from the place of water of water to the station;

- humidity and temperature at its installation;

- availability of free space for the convenience of repair and prevention work;

- isolation of the noise of the station from the residential premises.

Algorithm Installation of the Pump Station

Installation of the pumping station with their own hands consists of such steps:

- Drain tranches for pipes, it must have a bias on the place of water intake.

- Equipment passage for pipe in the wall of the house.

- Laying pipes in the trench.

- Attaching pipes to the pump.

Helpful advice: You should pay attention to the groundwater if they cost high, the pipeline is paved above the critical level. Pipes are isolated from the action of low temperatures.

The pump is installed on a special base. The legs with anchors are screwed to the base, it will give the entire system a stable position. Also for repayment of vibration under the pump, a rubber rug is littered.

How to install a pumping station with a remote ejector:

- Mount the ejector. It looks like a cast iron knot with outputs for a connection, three such outputs.

- In the lower unit of this node, the coarse filter filter is fixed in the form of a mesh.

- Signing the desired length is selected, it is fixed to the crop of plastic in the top of the node.

- Sign has two parts, each of which contains adapters. It needs to be assembled under the required diameter.

- A bronze coupling is put on the outlet of the camp, it transitions to a plastic tube.

- To ensure the tightness of all compounds, flax or tape sealant are used.

- Next, laying pipes and digging trenches, they are digging below the level of ground freezing.

- In the finished trenches lay pipes, they are taken with a margin. For casing, use a head chair or knee with a smooth angle.

- The pipe and the ejector are connected by the coupling.

- The lower end of the tube is put in the knee at right angles, and then lowered. All free space seal by mounting foam. The pipe is fixed to the adapter 90o and to the pipeline.

- The assembled ejector is lowered to the desired depth in the place of water intake. This value is marked at the beginning of all works, the mark is denoted at the level of the casing.

- On the casing, they strengthen the headband, for this use the sanitary tape reinforced.

Errors that should be avoided when installing a pumping station:

- When installing pipes, it is necessary to take all the values \u200b\u200bwith a margin. Often, when installing, it does not take into account all the bends, turns, as well as the thickness of the foundation if the station is installed in the house.

- All items spin only the key shrewd by manually and the zoomed connections can give to flow.

- The hydroaccumulator cannot be ignored. If the pressure indicator is below 1.2-1.5 atmospheres, it is raised using a compressor or a car pump.

How to connect the station to the water supply

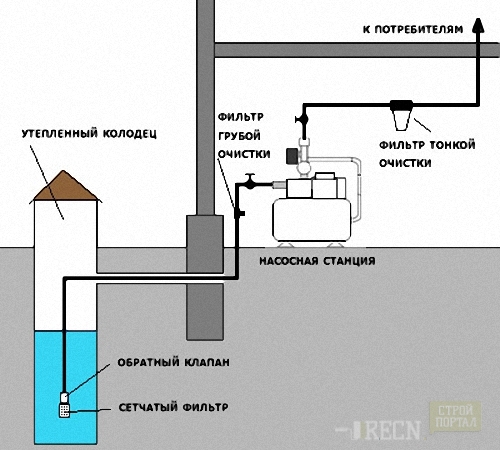

The need to connect the pump to the central water supply system may occur for various reasons. Often this is the imperfection of the water supply system and low pressure in it. The installation scheme of the pumping station to the water pipeline looks like this:

- In the selected place, the water supply pipes are disconnected and combined with a cumulative tank.

- From this container, water is fed to a pumping station.

- From the pump tube is given to the place of water supply.

- Mounted wiring.

- The pump is configured and regulated.

- Equipment setting is an adjustment of optimal pressure in the system.

About 2 liters of water is poured into the snail and follow, on what amount the pump will turn off and turns on. The optimal indicator for shutdown is 2.5-3 bar, inclusion - 1.5-1.8 bar. To adjust the pressure, use the screw with the designation "DR" or "P".

How to install a pumping station, in detail and clearly tells the video on this topic. Also, each manufacturer supplies its diagrams and detailed instructions. The overall installation algorithm is suitable for all units, but there may be some nuances and deviations that need to be found before connecting.

Install or not install a filter for a pumping station

An important factor that should be considered when connecting the station - the chemical composition of water and its physical qualities. Harmful impurities are contained in water from any source, it is impossible to allow them in the pumping station. To eliminate this problem, the device is equipped with a filter.

The filter prevents the accumulation of mechanical impurities in the hydroaccumulator and increases the service life of the pump. This is an indisputable advantage of filters.

There is a filter and negative sides. First, it creates additional resistance for water flow, reduces pressure and pressure. Secondly, the polluted filter can completely overlap the access of water to the station and bring it out of order. To avoid these troubles, the cleanliness of the filter needs to be very careful. In general, the filter installation is simply the necessary event.

Common malfunctions in the station and their elimination

- The pump rotates, but water does not go to the system. The cause of this malfunction is the depressurization of pipelines, such a situation arises due to the incorrect operation of the check valve, the absence of water in the system. To eliminate this problem, you need to check the availability of water in the system. If water is absent, it must be addressed through a special hole at the station or change the depth to which the pump hose is omitted. If after that the problem is not eliminated, it is necessary to check the valve and all compounds on tightness. If it did not help, it is necessary to check the health of the pump itself.

- The pump turns on very often and works unevenly, jerks. Most often, the reason for such a malfunction is the damage of one of the parts of the hydraulic panel. On the reverse side of the tank there is nipple, if water flows on it, then one of the pump membranes is broken and its replacement is necessary. Also, the cause of the malfunction can be the depressurization of the case. If the troubleshooting described is not detected, it can help solve the air swap problem into the tank using an ordinary pump.

- The pump is not started. Often it happens due to the lack of power. To eliminate the cause, you need to check the winding and contacts on the pressure relay.

- The pump is turned on, but does not rotate. The reason is a breakdown of the capacitor, the impeller joined the pump housing. Often this situation occurs after a long break in the pump work. To eliminate the impeller, you need to scroll several times, but if it did not help, the condenser is broken and it is necessary to replace it.

- The pump functions continuously, does not pause in work. The cause of this breakdown is a control relay malfunction. It must be adjusted using two springs located on the relay itself. Large in size regulates minimal pressure, smaller - the difference between the bottom and the upper indicator. Also, the reason may be blockage on the input opening of the relay. All work with this detail of the pump must be done very carefully.