What to choose: polyurethane foam or eco Building materials

Warming of houses is a very important procedure from which not only the indoor temperature depends, but also the ability to save on heating. To date, the most popular materials for the insulation are foam rubber and eco-insulation. These insulation are fundamentally different among themselves, so you will deal some of them really better.

Content

Theoretical aspects

Warming has several main goals:

- prevent cold penetration from the street

- keep heat indoors

- reduce gas consumption (coal, firewood) or electricity.

Based on these major tasks, two types of insulation are distinguished:

- internal

- external.

Internal insulation allows to increase noise insulation in hollow structures, for example, from drywall. In addition, such a thermostat does not need additional finish. Especially relevant to use internal isolation if the facade of the house is built of a beautiful brick that does not need additional decorative work.

However, this method does not allow creating a monolithic protective layer if it comes to two-storey or more buildings. Internal insulation does not allow high-quality insulation of plates of inter-storey partitions. Another disadvantage is to reduce the indoor space.

It has lower, compared to external isolation, thermal protection indicators. The dignity is that it is easy to manage a microclimate.

External insulation is especially true if the house is built from slag blocks or seven, as it will allow you to perfectly align the surface and save on plaster.

The disadvantage is that external insulation, even under the layer of plaster, remains soft enough and strongly subject to any mechanical damage. Therefore, additional costs will be required to clamp with a decorative stone of the lower part of the first floor.

External insulation is characterized by the fact that it creates an analogue of the thermos. In winter, it is very convenient, but in the summer it will be necessary to need air conditioning, otherwise they will be incredibly hot.

Now consider the materials themselves in more detail.

Polyurethane foam, characteristics

Elastic polyurethane foam is a general name for a group of materials that consist of inert carbonate gases and air (at the same time, the proportion of the binder is from 5 to 15%, the rest is airspace).

The commonly used name "Porolon" appeared due to the fact that in the Soviet Union, this product was represented by the products of the Norwegian company Porolon, which was further united with colleagues from Lithuania.

To determine the physical properties of the material, the following categories use:

- average density (kg / cubic meters) - 30-150,

- thermal conductivity coefficient (W / m * K) - 0.019-0.028,

- porosity - closed,

- service life - 20-30 years,

- operating temperature (° C) - from -160 to +150.

The density indicator characterizes the foam rubber, as a sufficiently soft material that is easily deformed and does not lose the holistic structure. It is worth noting that the structure is more adapted to the exposure to the bending than pressure. When squeezing, polyurethane foam works not correctly and faster comes into disrepair. In percentage ratio, the permissible reduction in size is 10%.

The thermal conductivity is the main trumpet of the foam rubber. The material is characterized by the smallest coefficient. This means that it warms or freezes only 2 mm, therefore, a layer of 5 mm will be sufficient for high-quality thermal insulation, and the layer of 10 mm will provide protection from the cold even in the most severe climatic conditions.

Closed porosity implies that polyurethane foam is one-piece material, the pores of which are concentrated inside.

Carbon, which is the basis of the foam rubber, is one of those elements that practically do not disintegrate and eventually become stronger. In the case of polyurethane foam, this leads to crystallization of the structure and loss of heat-saving properties. However, even for low-cost manufacturers, the service life exceeds 20 years if you buy modern products, they are operated for 50 years. Such a significant increase in service life is achieved due to a more thorough cleaning from various impurities of gases. Such polyurethane foam, whose price is not significantly higher, by the way, produced in Japan.

Limit operating temperatures, as well as the thermal conductivity indicator, are the highest among all thermal insulation. This is largely due to the fact that the foam rubber heats up and cools, nevertheless due to the presence of the air, it is very good and quickly lit. This is perhaps the only minus material. Special inert gases-catalysts are introduced into modern foam foams, which cause the reaction of carbon coking, therefore, the ignition is applied only under the action of an open flame. This property before buying is better to check on experience.

Biological and chemical stability should also be noted. In the first case, the polyurethane foam is quite reliable, since it is not subject to rotting, molding and the emergence of fungi, in addition, some components are harmful to rodents, so their appearance is excluded. The same is true and towards the roots of trees and herbs. For a person, the foam rubber is no less dangerous, in small doses it causes "breakdown of guts", in large - lethal outcome. Therefore, small children cannot be allowed to material.

Despite the fact that the polyurethane foam is chemically neutral, acids and alkali have a destructive influence on it, so it is not used in production facilities. The ingress of detergents has no consequences.

It is not accepted about sound insulation in the aspect of the foam rubber, as the material suppresses (removes noise, high frequencies, makes it more deaf), but does not drown the sound. This property is successfully used to produce headphones, pop filters and other sound equipment.

Polyurethane foam spraying

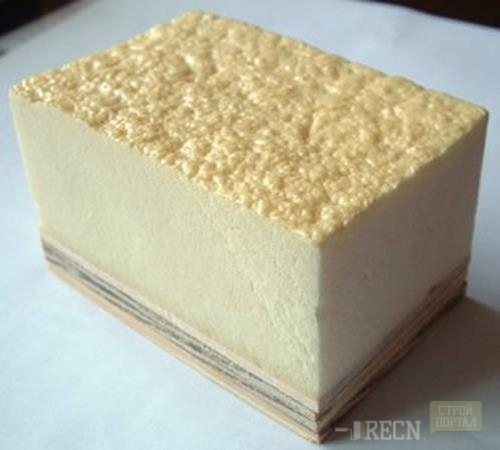

Usually, the foam rubber represents like sheets of soft porous material of yellowish color. But modern technologies allowed compressing polyurethane foam in a semi-parameter in a liquid state. This is an intermediate stage between the final hardening of the material and its production condition. In this form, its density is slightly smaller than that of the mounting foam, therefore special pulverizers are used to apply.

This method significantly increases adhesion and allows you to perfectly fill the angles, gaps and irregularities. After spraying, the porolon begins to expand increasing in a volume by 25-40%. The final hardening occurs after 30-36 hours. As a result, the coating is no different from ordinary polyurethane foam. The benefits are quite obvious:

- clause savings

- 100% isolation of hard-to-reach places

- performance speed.

Nevertheless, the cost of this service is sometimes much higher than the installation of standard polyurethane warmeter insulation. This is due to the fact that construction firms have not yet mastered the technology and there is practically no competition. It is impractical to buy equipment separately, since one-time use will not pay off costs. For professional builders is an opportunity to make it easier for themselves, make it better and get a lot of customers.

Important: Polyurethane foam is like a sponge, so it easily absorbs moisture. For the most material of the consequences, there are no, but moisture evaporation causes the risk of fungus on stone, a tile, plaster or a tree.

Equata, characteristics

Frequently often in the construction nomenclature uses the term of Minvata - it has nothing to do with the eco-art, as it is a mixture of fiberglass and various additives, the combination of which is harmful to humans. In turn, an eco-friendly or pulp insulation is a product of secondary processing of wood (paper), with the addition of non-rigging components.

The main distinguishing feature of the material is the lack of malicious evaporation and absolute security for a person. Among other properties, it is customary to allocate:

- density (kg / cubic meters) - 30-75,

- thermal conductivity (W / m * k) - 0.032-0.041,

- the combustible group - G2 is moderately combustible (GOST 30244), B1 (DIN 4102) non-flame (GOST 30402), D1 - with low smoke-forming ability (2.14.2 and 4.18 GOST 12.1.044),

- air permeability - low,

- parry permeability (mg / (m * h * pa)) - 0.3, sorption moisturizing according to GOST 17177.5 for 72 hours - 16%,

- chemical passivity,

- sound absorption (dB) - 63 with a thickness of 50 mm;

- shrinkage (per year) - 1.2%,

- service life 5-10 years.

The density indicator is not very different from polyurethane foam, so the properties are similar.

The thermal conductivity is above almost twice, therefore, the minimum allowable layer is 10 mm for a temperate climate and 20 mm for frosty. It should be noted that the operating temperature ranges from -40 to +120 0C. If there is no questions with the positive temperature, then at -45-50 0From the eco-friendly, it begins to crystallize and completely destroys.

The second combustibility group implies that the material burns very badly and only under the influence of a direct source of flame. In all other cases, the fire stops. In this case, the smoke is practically absent, and its components are practically harmless to humans (the effect can be compared with the smoking of the cigarette, only without impurities of sinyl acid, resins and nicotine).

Low breathability on one side allows you to prevent the penetration of the cold, but on the other it interferes with the walls of "breathing", which leads to the appearance of mold and fungus (if the rooms are wet or the standard air humidity of more than 70%, characteristic of marine cities and regions with abundant regular rains) .

The vapor permeability rate is significantly higher, which means that active evaporation is quite quickly displayed outward, while the material itself delays only 15-20% of the total moisture. This indicator cannot lead to the appearance of fungus.

Like polyurethane foam, eco-water is practically not subject to chemical impact. But, unlike a competitor, it is able to resist acids and solvents, therefore it is used in production.

Another plus is high noise insulation. For comparison, the armored door with a thickness of 200 mm has an indicator of 40 dB.

In contrast to the foam rubber, the shrinkage of EcoWati occurs every year. Because of this, the lumens in the slots will appear after 2-3 years, and after 5-6 years the thermal insulation factor comes to no completely. Some firms offer products that has a shrinkage ratio of 0.5-0.8%, but this does not significantly prolong the service life.

Together with the specified, the material has many other features.

Equata, Disadvantages

If in the case of polyurethane foam everything is quite simple, then with an emotor it is necessary to figure out more detail. Specialists are talking about the following factors, negatively affecting the choice in favor of this material:

- the impossibility of using for outdoor insulation,

- extremely slight service life, which implies overhaul when replacing the insulation,

- lack of a good distribution

- availability of low-quality products that does not meet GOST

- the availability of products with a violation of production technology.

The first two factors are not truly significant, since in practice, internal insulation is found much more often, and the repairs are made on average every 6-8 years. Nevertheless, the remaining indicate that the eco-friendly is not quite environmentally friendly and can harm health, especially if used in the children's room.

In order to protect yourself from fakes, it is better to buy only the goods of proven manufacturers.

Equidas and Favero manufacturers

Polyurethane foam you can buy both in the market and in specialized construction stores, the second option is preferable, because information about manufacturers is presented. Market leaders are considered:

- Porolon (Norway-Lithuania),

- NPO "Polypren" (Russia),

- Mixtek (France),

- "Hexel" (distributor, works with Germany and Poland).

At the price far ahead, only Mixtek escaped, rather due to the popularity of the brand, rather than due to the quality. On average, the cost of one square meter of the leaf foam rubber is from 100 rubles. If we are talking about spraying, it increases to 300 rubles.

Equata, the price of which is significantly lower (from 1500 rubles per cubic meter), is produced either on an industrial scale or by a handicraft. Specify specific firms make no sense. First, the cost of equipment for working with the material is from $ 5,000, and secondly, companies providing this service have already accumulated, proven contacts with cellulosic insulation suppliers.

In conclusion, it is worth noting that the polyurethane foam is much more practical and more convenient. The areas of its use is much wider, while it is easily mounted independent. The only visible advantage of eco-house is the speed of work.

Another restriction refers to the operation mode. The foam rubber is neutral to evaporation and high temperatures, and Equata begins to decompose at the same conditions, as a result, its fire-fighting properties are practically no (it is categorically forbidden to use in baths, kitchens and boiler rooms).