Features of the installation of the stained steel ceiling do it yourself Ceilings

Choosing a room design or all at home is not a simple thing. With a huge number of new materials, textures, colors are not so easy to stay on something one. One of the main elements of the room design is the ceiling. From the correctness of the shape and color of the ceiling depends on the overall picture of the room, which can both emphasize the basic idea and spoil it.

Content

Characteristics of ceiling structures

Basically, when repairing apartments and houses, suspended ceilings are currently used. Moreover, both single-level simple designs and multi-level with asymmetric lines, various patterns. Multi-level ceilings are also used with a large curvature of the main overlap, when fixing it with plaster will be problematic.

For the device of suspended ceilings, the following materials are used:

- Plasterboard. The easiest and cheapest option. Especially if work on putty and painting are performed independently. Plasterboard ceiling is characterized by excellent performance, not afraid of mechanical damage. However, the time of its construction, taking into account putty and painting, very large.

- Vinyl film. Such ceilings are still called stretch. Quickly mounted, do not require further processing, have a wide range of colors and drawings. The disadvantage of the stretch ceiling is complex installation (as a rule, performed by specialists) and the fear of mechanical damage. Cork from under champagne or unsuccessfully desposed ball can make a hole in it.

- Glass ceilings. Modern design direction. They look simply amazing, especially when mounting the backlight. They have excellent operational qualities, however, the cost of such a ceiling is higher than other systems.

How to make a stained glass ceiling with your own hands - further in the article.

Advantages of stained steel ceilings

Before you choose your choice on a stained glass ceiling, you must analyze its advantages and disadvantages. The main strong parties are:

- Practicality. Care for stained steel ceiling is very simple. From time to time it is only necessary to rub with a damp cloth. The glass does not absorb dust, not dull, it is not necessary to repaint it. Unlike drywall, the glass ceiling is not afraid of moisture. Also, the glass is not affected by the change of temperature in the room, which is beneficial to its vinyl.

- With proper operation, the glass ceiling can last for a long time.

- Easy installation. Installation of a glass ceiling is not too different from other designs. However, in contrast to the drywall, it does not require putty and painting. When installing, a standard fastener is used, which is noticeably easier.

- Beautiful appearance. Beautiful stained glass windows on the ceiling will be able to create an unforgettable atmosphere in the room, emphasizing the main direction of design.

- A large number of different colors. The choice of stained steel ceilings is really wide, so that it can be selected in the drawing and coloring for a common interior.

The disadvantages include:

- relatively high cost

- fear of mechanical damage.

Types of stained glass ceilings

With the advent of the popularity of this design technology, several excellent types of stained steel ceilings were developed. They differ in both the method of applying a picture on the surface of the glass and the production technology of the entire design.

By the method of applying a picture on glass Glass ceilings are divided into:

- Film ceilings. Consist of two separate items. The basis of such a ceiling is the usual glass, on the surface of which a film is applied with a given pattern. At its price, this type of ceiling is the cheapest, however, at the same time does not have high performance characteristics.

- Stained glass ceilings. Consist from a large number of small pieces of stained glass that form an interesting pattern. They are characterized by a high degree of reliability and excellent performance. Copper or lead accommodation is used to connect stained glass. Stained glass ceilings look great both in residential premises and public places.

According to the production technology, glass ceilings are:

- Sandblast. This is the most commonly used processing of glass surfaces. Thanks to the exposure to the sand jet under high pressure, the top layer of glass is destroyed, and it becomes matte. Due to the contrast between the matte and transparent part, the pattern is achieved, for which stencils are used. The closed piece of glass during processing will be transparent, open - matte.

- Printed ceilings. Naturally, print any drawing on the surface of the glass is problematic. To solve this problem, the drawing is applied to the surface of a special film, which is already glued on the glass. This technology appeared relatively recently - from the time when the wide-format color printing has become available. It allows you to make a ceiling of any color with absolutely any pattern: from abstract, to the photo, which expands the capabilities of designers.

- Contour stained glass windows on the ceiling. Products with more complex production technology. Special contours of future drawings are applied to the glass surface. For this, polymer sides are used. Then inside the outlining of the pattern poured the paint of the desired color and the shade (the enamel is most often used) or varnish. Due to this, such glass is also called bulk.

- Stained glass window on Tiffany ceiling. This technology is different from ordinary stained glass ceilings in that each piece of glass along the contour is wrapped with a copper or tin foil. Such technology is successfully used to create not only horizontal ceilings, but also dome. There are such ceilings with their grace and nobility, but their cost is much more than that of other species.

Installation of a stained glass ceiling

Due to the fact that the glass is a rather fragile and expensive material, the installation of a glass ceiling is better to entrust professional installers. However, if you try, you can make this work yourself, just need to be attentive and neat.

Methods for installing glass ceilings are several.

- Glit glass plates to the ceiling. For this work, it is necessary to have an absolutely level surface. Therefore, experts recommend glue materials not on a rough ceiling, but on lined with plasterboard. Polymer adhesives are used for fastening glass, such as liquid nails. The big problem is the installation process itself. Before the glue is grabbed, the tile will have to keep the hand. This method is not too popular, as it has some limitations. It is impossible to mount too heavy material, as well as transparent glass (the glue stains will be too noticeable through it). It will not be possible to set the stained glass window on the ceiling with backlight.

- Installation on special screws. In this case, the glass is attached to a wooden or metal crate, which is installed on the ceiling. For fasteners, special screws are used, which are inserted into the hole drilled in the glass. You need to drill them very carefully so that the glass does not cracked from overheating.

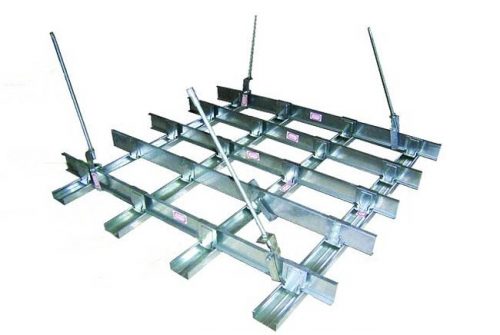

- Fastening to the Armstrong system. Such a system is often used to arrange suspended ceilings in office space, but perfectly suitable for apartments or houses. To install in such a system, standard glass tiles are 600x600 mm in size. The advantage of the Armstrong system is the simplicity of repair and replace its individual parts.

The whole process of work can be divided into several stages:

- Marking ceiling. This is one of the most important stages of the fabric of the glass ceiling. Therefore, it is necessary to approach it very responsibly.

- Installation of suspended fittings (corners, profiles, anchors, suspensions).

- Installation of glass profiles.

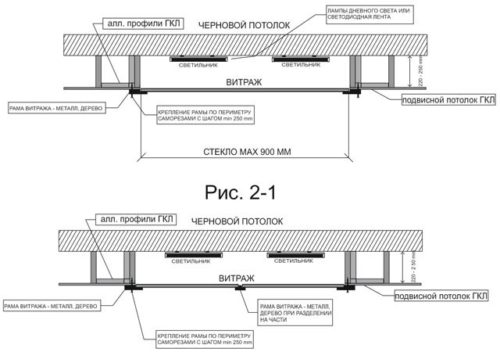

- Ceiling backlight system.

- Installation of glass tiles.

The order of installation work is as follows:

- The first thing in one of the angles of the room is set by the label of the height of the suspended ceiling. Next, the same mark is installed in all angles. For applying the same tags using a laser level.

- Next, you need to find the center of the ceiling. For this corners are connected by diagonals. At the intersection of diagonals and there will be a center.

- Then, on each of the walls, the middle is postponed, which is connected by the line from the middle of the ceiling.

- Now you can draw the line of installation of the dowels. From the central line on each of the opposite walls, 120 cm is deposited, and the line is carried out again.

- The following places of installation of the dowels are scheduled.

- Then, in each of the angular profiles at a distance of 300 mm, the holes for the installation of the dowels are deplorable.

- Next, you should learn a profile to the wall and with the help of Kerner to outline the places of future holes.

- At the outlined places, the holes in the wall are drilled to which the corner profile is attached. It is done throughout the perimeter of the room.

- Further, the guides are emerging in the corner profile, which will be the basis of the system. Guides are connected to each other and are attached to the ceiling with special hooks-suspensions.

- When the system is mounted, the wiring for organizing the backlight will be started and mounted. To do this, it is better to use LED lamps. They consume less electricity, and do not heated.

- The last stroke will install the glass. To do this, it is necessary to cut them into squares with a size of 600x600 mm and start in special grooves.

Stained glass window: Photo