Universal metal staircase with her own hands Ladder

Usually, universal metal stairs are called a stepladder. The stepladder is a portable staircase, which is expanded to perform certain works. It has several advantages over the gear, and besides much safer.

Content

Universal metal staircase and its purpose

The stepladder is a multifunctional tool. He found widespread use in construction and everyday life, main tasks:

- shook wallpaper;

- whitening ceilings and walls in homes and apartments;

- harvesting fruit-berry trees;

- work with electrical lighting devices.

In order to understand how a universal staircase is arranged, it is necessary to consider its components. Elements of the stepladder:

- stages 4-10 pcs, it is worth noting that the more steps, the less stable the staircase;

- front racks to which steps are attached;

- rear racks are installed for equilibrium;

- top pad, used as the last step, has a sufficient width, in order to fully stand with two legs, therefore, both hands are used to work;

- the belt is intended to ensure that the staircase does not drive around, install in the middle;

- plastic or rubber tips for the legs so that the staircase does not make holes in the floor.

Sometimes, equipped with handrails and trays for tools.

Produced from:

- metal;

- aluminum.

Types of universal metal stairs

Initially, all stairs were made of wood. This material is extremely unreliable, quickly decomposes under the influence of negative environmental factors and does not withstand a larger load. This led to the fact that most modern stairs are made of metal. Higher strength of the material allowed to modernize the classic stepladder, therefore several varieties appeared.

- fireflowing;

- swiss swift, or telescopic;

- swirling transformer.

Metal stairs, photos of which are presented below, will clearly demonstrate a variety of execution options. Now more about each of the types:

1. The dispensing device is described in detail above.

2. Sliding stepladders are similar to the breakdown, as the exception, which consist of two or three sections. If necessary, increase the length of the stairs, the next section gets. This method increases mobility and significantly expands the functionality.

3. The transformer string is the most multifunctional and universal staircase. It is able to take a variety of forms, from the classic perturbation stairs to the construction goats. Thus, one tool allows you to perform a fairly wide range of works. To date, this is the most relevant model. Elements of gear transformer:

- steps 6-20 pcs.;

- 4 sections that are capable of taking various forms, for example, transforms into a two-way ladder, a working platform, anxulated staircase;

- frame;

- rubber linings on the legs.

The height of the lap transformer in the unfolded form reaches up to 6 meters, and the maximum load is up to 200 kg in any of the provisions.

Materials and tools for work

The choice of materials is small or aluminum or metal. We will talk about their advantages and minuses.

The advantages of aluminum stepladder:

- Aluminum is much easier metal. Therefore, the aluminum ladder is much easier to transport, even in public transport.

- Since it is a non-ferrous metal, it is not subject to corrosion and other negative environmental factors.

- Does not need a primer and painting.

- The service life is limited extremely the quality of the assembly of the stairs.

Disadvantages of aluminum stepladder:

- Large electrical conductivity. As a result, it is impossible to use for the repair of high-voltage lines. In everyday life, such a need is extremely rare.

- High thermal conductivity. When working outdoors, aluminum is heated faster and stronger than metal. If you leave the staircase in the sun literally for one hour, then it will be impossible to work on it.

The advantages of the metal stepladder:

- Ease of manufacture.

- Availability of materials.

- Higher safety margin.

Disadvantages of metal stepladder:

- Permanent painting and control of corrosion, which requires energy and time costs.

- With poorly performed welding staircase on a metal frame, there is a risk of destruction of the structure. As a result - injuries.

Regardless of the material from which the staircase is made, you need to comply with the standards of standardization on the electrical protection. To them:

- electrical strength, which should be at least 2.5 kW per 1 cm length of the design element;

- electrical resistance is at least 500 ohms when an alternating voltage is exposed to 50 Hz for a long time.

Conforming these characteristics, the ladders, in contact with electrical equipment, should ensure reliable insulation throughout the long life.

In the factory conditions, it is easy enough to achieve such indicators, but making a universal staircase with your own hands it is possible only if you fully cover all metal pieces of rubber or closed them with a tape.

Regardless which material is selected, it will take to work:

- roulette;

- corolnic;

- simple pencil;

- hoven for metal;

- bulgarian;

- drill;

- screwdriver slot 4 mm;

- sandpaper 2-3 mm;

- hammer;

- metal drills;

- bolts, nuts;

- welding machine.

In addition to the tool, you need to stock consumables. Among them:

- chain or belt

- rubber knobs for legs;

- glue for metal or liquid nails;

- metal sheet for cutting steps and connectors;

- metal profile or pipe.

Depending on the situation, you will need an additional inventory, but this concerns only those cases when there is a need to assemble a decorative staircase.

Instructions for assembling classical folding stepladder

Consider the option of making metal stairs:

- Make a sketch of the future stepladder.

- Take a metal profile or pipes. Their length is determined by the height of the stepladder. Cut off the 4 identical piece of pipes on which immediately remove a large rust, for this use a grinder or drill with a special nozzle.

- Secure the pipe in the vice and clean it up to the brilliance or use the means against rust.

- Cut the steps of the same length of the metal sheet, they also clean them from rust.

- Tracing the steps on a flat surface.

- To weld the steps, if there is no welding, then use the corners and bolts with nuts.

- Tingering the plugs on top and bottom of the pipe.

- On the bottom to glue the rubber knobs.

- Take the remaining 2 pipes and weld to them from above and below the crossbar at a distance of 10-20 cm from the end of the pipe.

- Drill in the middle of the pipe holes and fasten belts bolts.

- To half the stairs without steps to weld one metal plate perpendicular to the pipes. To another half of the pipe with steps to fasten 2 metal plates. From above which to privar the top steps.

Advice: Plates on the halve with steps are screwed on the lock nut so that they can be freely spinning. For more reliable fixation of them, it is better to make ropes at the level of the support plate, the lock is formed so.

- Progress and paint.

Advice: The described design was not very convenient in the transportation. To make her monolithic soulfit with steps make longer. 10-15 cm above the last steps in the pipes drill or cut the gaps in which the ends of halves are inserted without steps. They must be sustained with a hammer. Next is drilled through a hole, and the design is fixed on the counterparty.

Universal aluminum stairs are manufactured by the same principle, the exception that argon-pressure welding and rivets are used instead of screws.

Assembly Instructions Stirring Transformer

Make an independently swirling-transformer larger than the classical one. To do this, you will need the same tool and materials, with the exception of belts. Stop mechanisms will be used instead. But the procedure is different:

- cut eight pipes of the same length;

- cut the steps, the step is selected independently, there are no specific requirements for this point;

- stages to position so that with both ends of the sections there was the same distance to steps;

- make fitting and cook sections;

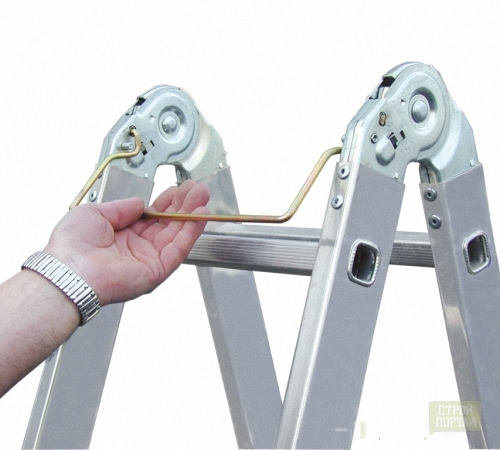

- connect sections with each other by locking mechanisms. The load on them in the position of building goats is quite high, so the welding seam must be as high as possible;

- process the staircase of the primer and open the paint.

The staircase is universal ready for operation. It is advisable to lubricate the locking mechanisms with machine oil.

Separately consider the technology of the assembly of the sliding staircase no meaning. It is a synthesis of trannemer and classics. Sections are manufactured according to the principle of transformer. Between themselves are connected by a sliding mechanism. And the last two sections are attached on the principle of classical stepladder.