How to make a bourgeois Baths, saunas and pools

Heat the garage in the winter, the country house, the womb or a small utility room is the easiest way with the help of burzhuyki. It can also be prepared or warm up food. As a fuel (depending on the design of the bourgeities), spent machine oil, firewood, coal, rags, wood waste and even household garbage can be used. This heating device is quite easy to manufacture. In this article, you can familiarize yourself with the device and with information on how to make a burgundy.

Content

How to make a bourgeois from the gas cylinder

First of all, it is necessary to prepare cylinders for work, otherwise an explosion and a fire may occur. That this does not happen, carry out the following actions.

- We unscrew the valve and we release the gas remaining in the container.

- I turn over the balloon so that the condensate can be drained into specially prepared dishes. This should be done cautiously: the liquid spilled on the floor is absorbed into the coating and will have a long scent for a long time.

- We establish a balloon on the bottom and completely fill in water: it will displace the remains of the gas.

- After the water is fused, any operations can be made with a balloon.

How to make horizontal burzhuyk

In some cases, such a design will be more convenient, for example, if firewood will be used as fuel. To your attention - information on how to make burgundy on firewood.

- With the help of a grinder, we cut the top of the cylinder (there will be a stub it will be welded).

- From the construction reinforcement, we produce trees: the rod is cut into pieces of the required length, which are welded in the inside of the cylinder.

- For the device input to the furnace in the bottom, the rectangular opening is cut into the bottom. The carved portion is used for the manufacture of the door. Initially, it is brewed with a strip to it weld the loops and the handle, and then installed in place. On the perimeter of the doors we glue asbestos-cement cord.

- At the bottom of the cylinder drills holes: the ash from the furnace will be hurry through them.

- For the collection of ashes, the removable dealer from the sheet metal is Rashnik. He will also play the role of confused, for which it is also required to equip the door.

- From the corners or trimming of pipes we make legs, which are also welded at the bottom.

- To install the chimney from above near the distant edge, cut the round hole. We weld the pipe from metal to this place.

- To prepare food, a steel frame from fittings can be used as a cooking panel.

So you can get more complete information on how to make a burzhuyk: video with explanations of the author:

How to make a burzhuyk vertical type

Vertically installed burzhuyka takes less space. If coal is used as fuel, such a system will be more successful. It is possible to make it from a pipe or bent sheet iron. Let's tell about how to make a burgundy from the barrel.

- We place the places for the door to the furnace and in the ash tank: the first must be greater in size and located at the top of the case. The door in the ashpan is smaller in size, installed under the entrance to the furnace.

- The grinder cut out the planned sections and the doors are made of them as described above.

- At a distance of about 100 mm below the door to the furnace, we set the sparkle from the reinforcement. Brackets are welded in the calculated place to fix it.

- Songs of the pipe or corners are welded to the bottom (they will serve as legs).

- The pipe is welded at the top. It is possible a side exit device, but in this case the knee will be required. Chimney can be connected to a common system overlooking the street.

- In order for the furnace to be safe in operation and aesthetically attractive, burgers are scattered, and the housing is covered with heat-resistant paint.

In the event that a pipe is used for the manufacture of bourgeitors, its upper and lower parts are brewed with sheet metal. Similarly, the stove of rectangular shape is arranged: the difference is only in the appearance of the case.

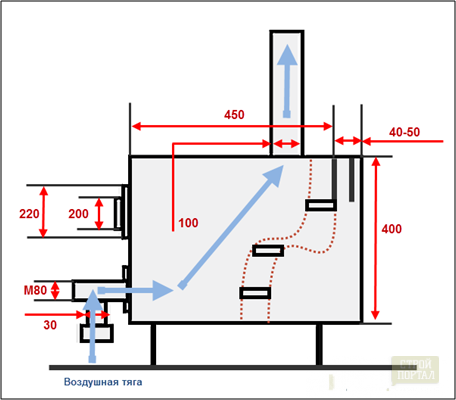

How to make a burzhuyka on working out

Such a heating device is not suitable for use in residential areas: a specific unpleasant smell is distributed when oil combustions. But in the technical premises you can use such a bourgeitogo. They are used, for example, on auto repair enterprises, where there are access to waste machine oil.

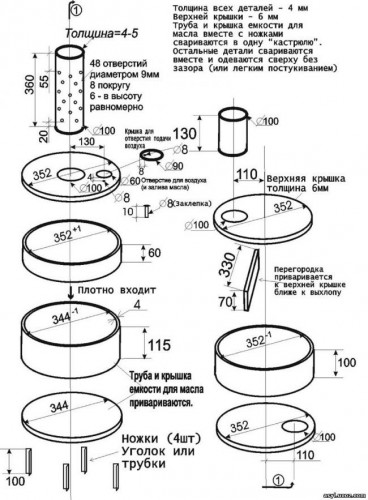

Burzhuyki Development Device

The heating device consists of three main parts.

- Fuel tank with removable lid: This is a container that is filled with oil on 2/3 of its volume. The tank also serves as a primary combustion chamber. Its diameter is about 350 mm. In the upper part - a hole with a diameter of 60 mm for refueling with an oil, through which air also enters the combustion chamber. Adjust the amount of air with a metal damper attached to the screw to the tank cover.

- The upper combustion chamber: there is a process of combustion of oil mixed with air, with the result that heat is highlighted. In the upper part there is a hole - the output into the chimney. The size of the combustion chamber is the same as the fuel tank.

- Pipe connecting combustion chambers into one system. Pipe diameter - 100 mm, length - 400 mm. Uniformly in the pipe wall is hampered by a hole with a diameter of 10 mm: it is necessary to provide air access to the second chamber.

On the principle of work of the stove on spent oil

In the fuel tank through the filling hole, the exhaust oil is poured (on 2/3 of volume) and is set on fire. Fuel consumption is directly proportional to the volume of the tank. When burning, thermal energy is distinguished, which will be enough for heating with both working chambers.

Mixing with air, unburned volatile connections to be trembled in the upper chamber, increasing the temperature of the stove to 800 degrees. In addition to the cameras, a source of heat also serves a tube, the walls of which are heated by a hot and chimney, built in the form of a labyrinth.

How to make a bourgear in the garage: manufacturing technology

- We purchase a sheet steel with a thickness of 4 mm and the pipe with the walls of the same thickness.

- Cut the parts (dimensions are specified in the drawing).

- The edges are processed by the emery circle.

- In the pipe drill holes Ø10 mm.

- In the lid of the top tank with the displacement to the left, cut the hole for the chimney. At the bottom of the displacement to the right - a hole for the connecting pipe.

- In the first (bottom) chamber, the pipe hole is cut in the middle. Next to it is another hole with a sliding lid - to refuel the bourgearies with oil.

- For greater strength of the connection and stability of the system between two cameras, the bracket is welded.

- The bottom of the bottom chamber is equipped with legs.

- After welding, all seams are cleaned, the housing is covered with heat-resistant paint and the finished stove is connected to chimney.

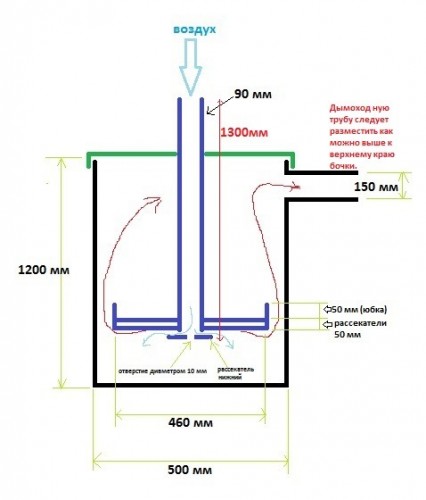

How to make a burgundy long burning

How to make a bourgeois stove, in which it would not be it would be easy to load fuel? It is possible to achieve a long-burning effect with the help of the pyrolysis process. This implies a special order for laying firewood in the fuel cell. Such actions The stove is called "Bunch": the fuel is on top of it.

For the manufacture of "bubfoni" need a channel and a large-diameter metal pipe. A barrel is also suitable.

Sequence of action in the manufacture of the stove.

- The top of the barrel is cut down, the edge is aligned.

- The cover is made from the metal sheet, in the upper central part of which a pipe hole is cut for a diameter of 100 mm for air supply. The height of the pipe should be a little more height of the stove itself.

- In the upper part of the pipe (barrels), a pipe-chimney with a diameter of 150 mm is welded.

- Damn (upper divider) is welded to the bottom of the pipe, reinforced by reinforced with corners. As the firewood, it will descend down.

- Under the top is the lower divider by a smaller diameter, in the center of which should be a hole Ø10 mm.

- All items are collected: the pipe is entered into the lid and is installed in the casing of the bourgear.

In such a stove, the fuel burns in layers. Depending on the loading of the burzhuyki, the full combustion time can reach 60 hours.

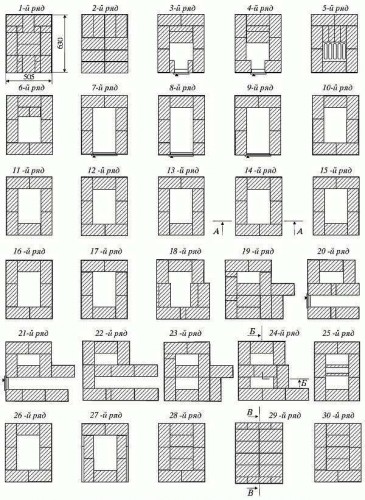

How to make bourgeyque brick

Ceramic brick is a refractory material with good thermal insulation properties. You can also use chamotte brick. With it, you can build a stationary stove-burzhuyk. Do it is necessary on a solid foundation, near the wall. It is required to comply with the following rules during operation.

- For the foundation, a hole is a depth of 0.5 m, in which 4 sand buckets are falling asleep, which should be tamped. The next layer is rubble (about 0.15 m), after which everything is covered with a layer of cement mortar.

- After drying, two layers of waterproofing material are stacked and a masonry is performed according to a specially calculated scheme-order.

- The first row is put in a quarter of a brick (on the edge). It is important at one level to lay out all the bricks, as in the future it will affect all the masonry. The remaining rows are erected in Polkirpich.

- The horizontal of the rows and the vertical position of the walls are periodically verified using Waterpas and a plumb.

- The furnace should be at the level of the 5th row. Its sizes are in three rows of height and two bricks wide.

- Bricks are put on a clay solution with an admixture of sand and cement.

- The pipe can be made of metal with a thickness of at least 3 mm and a cross section of at least 120 mm and output it through the wall or roof.

- Walls adjacent to the furnace protect against high temperature sheet metal or asbestos.

Burzhuyki device on sawdust

Sawdles are not burning too well. But on wood processing and furniture enterprises such fuel in abundance. For its burning, the stove is manufactured according to the following rules.

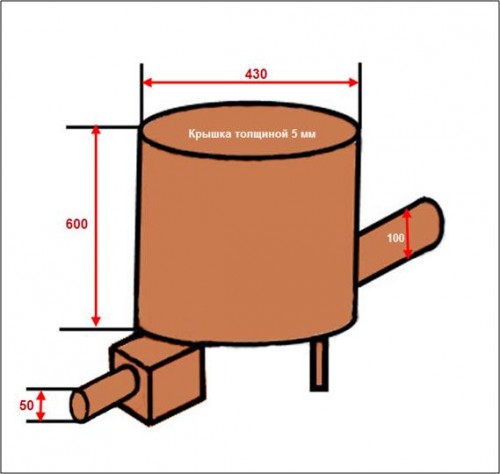

- Bourgehog, adapted to layers, consists of internal and external cylinders. The latter is a box, for the manufacture of which the sheet iron is used with a thickness of 2 mm (for the bottom it is necessary for a thickness of 4 mm thick, for a cover - 5 mm). Control height - 0.6 m.

- In the bottom of the external cylinder, a hole with a diameter of 50 mm is cut, to which the welding of a pipe 25 mm height for removal of heated air is fastened.

- Having retreated 470 mm from above the pipe with a diameter of 100 mm (chimney).

- In the upper part of the cylinder is suitable for gas shutter.

- Solnik is made of a steel sheet of 3 mm thick. It is equipped with a door of 210 × 140 mm (for the device pondered).

- The inner cylinder is made of thin steel sheet. Its dimensions: height - about 570 mm, diameter - 370 mm.

- In the bottom of the inner cylinder make a hole with a diameter of 50 mm with an edge of 10 mm height.

- For molding sawdust use a core in the form of a truncated cone with a handle. Its length is 600 m.

At the end, we propose to watch a video, a clearly demonstrating the process of manufacturing bourgearies with a combined method (from brick and gas cylinder).

New comments

Add a comment

To send a comment you need authorize.

http://recn.ru/kak-sdelat-burzhujku. Normal such article!