Types and characteristics of insulation. How to make the right choice Building materials

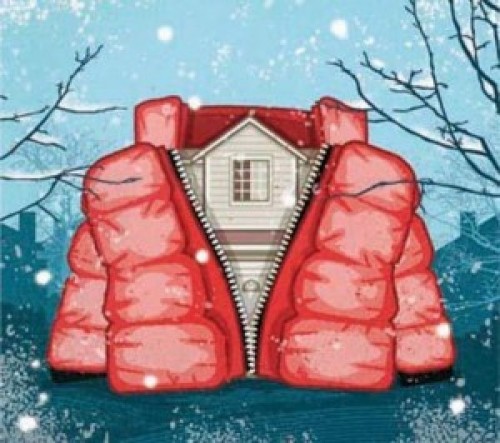

The insulation of the premises allows not only to reduce heating costs in the cold season, but also helps to keep the coolness of the hot summer. To get the maximum benefit from thermal insulation, it is important not to make errors when choosing insulation and its installation.

Content

What are the insulation

Choosing the material, it is necessary to focus on the basic requirements for insulation:

- low thermal conductivity;

- moisture resistance;

- sufficient vapor permeability;

- low weight;

- durability;

- fire resistance;

- environmental Safety.

Externally, insulation can be represented as:

- Bulk materials - clamzit, granules from the foamed substance.

- Wool - materials from fibers. Wool is available in rolls or plates. Roll insulation is prone to slip, it should not be used for walls.

- Mates are a sealed wool glued with a synthetic basis or one-layer.

- Plates of organic material.

- Cotton plates formed from plates with different characteristics.

- Wall blocks or panels made of foam material.

Chemical composition and method of manufacturing insulation determines its properties and quality.

Mineral wool

Minvata is a fibrous material from melts of metallurgical slags or silicate rocks. Mineral wool is a non-combustible material, has low thermal conductivity and high sound absorbing indicators.

The disadvantage of Minvati is its high water absorption, it reduces the service life of the material. With such a disadvantage, it would be possible to put up if not to be taken into account that Minvata is one of the most harmful building materials.

Formaldehydes that are part of the Minvati are highly toxic materials and are able to cause serious harm to health. Do not use mineral wool for internal housing insulation.

Insulation Ekwata.

Eco-friendly material - for the manufacture of which is used cellulose. It is used for the outer insulation of walls, gender, roof. For applying, special deposition settings are needed.

Application is convenient because the special cutting of the material is not required. Sprayed material fills all the recesses and seams on the surface. For horizontal and inclined surfaces, dry spraying is used for vertical - wet. After drying, the EcoWat creates a reliable protective layer that does not settle and cracks.

Fiberglass, glass gamble

Insulation of fiberglass, or glass gamble, is produced in rolls or plates with sufficient rigidity. It is used for the insulation of any surfaces and overlaps - walls, roof, floor, slopes. The disadvantage of such a insulation can be called the complexity of the work - requires protective clothing. The glass gamble absorbs moisture well using it for insulation take care of vapor barrier.

Basalt Ministry of Flight

Basalt mineral plates are distinguished by fire safety and have low water absorption. Have a different degree of rigidity - soft, semi-rigid, hard and super-grade mineral basalt plates.

They are a good insulation for sandwich panels.

After mounting on the plates you can apply a plaster layer and produce further finishing finish.

Ceramzit

Ceramzite is obtained by firing clay rocks. Ceramzite gravel has dimensions from 5 to 40 mm. Used for thermal insulation of the floor, overlaps and roofs. It is not subjected to rotting, resistant to temperature difference, does not burn. Ceramzite is also used to join the foundation, which warns the freezing of the soil.

Foamed granules

Granulated foamed polystyrene is used for heat insulation of the floor and the foundation, roof, as well as as a filler with a cement screed device. Light Heat Granules are 3-4 mm. The use of such granules to fill the space between the main wall and the drywall over the plasterboard allows you to fill the entire space and avoid the appearance of cold bridges.

Polystyrene foam plates and blocks

Foam polystyrene or foam is most often used from polystyrene foam insulation.

Advantages:

- Low weight.

- High strength.

- Low cost.

- Easy installation.

- Low hygroscopicity.

Disadvantages:

- It has insufficient sound insulation.

- It has low vapor permeability.

- Polystyrene foam, made with compliance with the rules of technology is self-tapping material and does not support combustion. If it is burning, the material manufacturing technology is impaired. However, one should not forget that in a fire, the foam begins melting, highlighting the caustic smoke, which contains phosgene. Phosgen causes paralysis of the upper respiratory tract.

- Polyfoam does not breathe. The probability of the appearance of fungus is very large. The saddest thing is that you do not see it, because The fungus is multiplied between the main wall and insulation. Indoors.

- It is not recommended to insulate the walls of the wall and the ceiling indoors. Violation of technology with the insulation of the facade reduces the service life of the foam to 7 years.

- The price of the insulation from the foam is much lower than other materials. It is easy to work with it. Using the foam for insulation, think about what is more important - low cost, or security.

Features of the insulation of apartments in high-rise buildings

When insulating the apartment in high-rise buildings pay attention to the outer walls, the floor, the window slopes.

On the last floors, ceilings are insulated, the residents of the first floors often have to engage in the insulation of the floor.

Works on the insulation of walls inside the premises do not bring the expected results, and sometimes they give an undesirable effect - the wall begins to freeze. The moisture is assembled under the insulation layer, which creates favorable conditions for the development of fungus and mold and increases the thermal conductivity of the wall.

It is difficult to deal with the insulation of the wall outside it is difficult due to the lack of necessary equipment and experience at height. In such cases, refer to the services of industrial climbers. The high cost of work will eventually be justified by the high efficiency of insulation.

With the outer insulation of the walls, the dew point moves to the surface of the wall and the possibility of evaporation of moisture into the atmosphere appears. The probability of the appearance of harmful microorganisms is minimized.

If there is no possibility to insulate the walls outside the building, the choice of insulation for walls must be approached especially carefully. When internal decoration requires vaporizolation. It is important to exclude the possibility for thermal insulation to absorb moisture. Otherwise, thermal insulating materials lose their properties.

When insulating walls, it is necessary to observe the following order from the inside:

- Wall.

- Insulation

- Parobarrier.

- Plasterboard.

- Finish finish.

The system of forced ventilation will help to avoid high humidity in the room.

Features of insulation at home

When insulating the house, all sources of heat loss are taken into account. Walls, roof, foundation, floor, window and doorways - everything needs to pay attention.

When choosing a heater for home, it should be considered from what material the walls of the house are made.

To warm the wooden house, it is better to use glass wool or basalt insulation. Be sure to use a layer of vaporizolation.

Before buying a heater, consult with experts. Prefer products of well-known manufacturers - Knauf, Ursa, Ivo. Combine and combine different types of insulation.

Observe the technology when performing thermal insulation. This will extend the service life of materials and securely maintain heat in your home.

Characteristics of the insulation escape.