Sandblasting apparatus do it yourself Instruments

Sandblasting machine is a device used to matting glass, removal of scale and dirt from the surface of metals, removing old paint, etc. It can have different designs, but its essence comes down to one: the device throws under the high pressure stream, mixed or with air or with water, and it is heading to the surface that is subject to processing.

Content

Types of sandblasting machines

Sandblasting devices are:

- Pneumatic - lead a sandy jet into translational movement with air.

- injector;

- pressure.

- Hydraulic - lead a sandy jet into a translational movement with water.

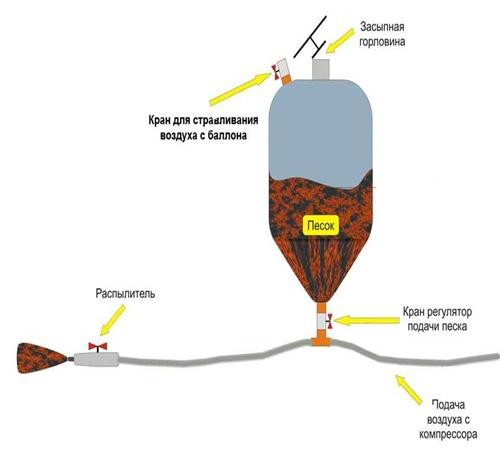

The most common is pneumatic. Pressure devices work as follows: The air flows come inside the installation, as well as to the node, dosing abrasive particles. Next, mixing, they enter a special sleeve, ending with the nozzle specifying the direction and shape of the jet. The feed rate of the air-sand mix is \u200b\u200bvery high. Due to this, it is possible to deeply and qualitatively clean various surfaces in large quantities.

The injection machine is arranged somewhat differently. Air flow and abrasive particles are moving in different sleeves. Ultimately, the air falls into a cooler equipped with two nozzles. One abrasive, second is air. There is a discharge between them, thanks to which the abrasive mass is assessed. The speed and force of the pressure in this case is much lower than in the previous version. Therefore, the injection machine is used in the presence of a small amount of work. But it is cheap compared to the pressure device.

Sandblasting diagram:

Sandblasting apparatus do it yourself

If the acquisition of this technique is a necessity, and the budget is limited, the construction of a home-made sandblasting machine can be an acceptable output.

The easiest option is the sandblasting gun, which is a handle, tip and two fittings. One of them serves to transport compressed air, the second - for suction of sand.

First you need to pick up the nozzle through which the air-sand mixture will be released. It is better to purchase it ready, because Homemade will not correspond to the required quality. It should be made of carbide, tungsten or boron. Such a nozzle will last a very long time, unlike ceramic or cast iron, which will wipe the maximum for a few hours. Because The sand abrasion is extremely high and moves at high speed, the output channel is rapidly wear out.

Nozzle must be purchased first of all, because the body of the gun is pulled under its size. Next to it will be attached to the handle and both fittings. For the assembly of the simplest sandblasting gun, water fittings are required, a tee and a plastic tank for sand, which can serve as an ordinary bottle of soda or mineral water.

As can be seen from the above, the sandblasting device does not constitute anything complicated. Such a device is easy to mount for several hours. Sand covered in the cropped bottle, after which the pistol join the compressor or highway feeding compressed air. Here it will be necessary to buy or take somewhere for rent.

What material is best used as an abrasive

Ordinary sand from the street is not suitable for sandblasting surfaces. It consists of various-caliber fractions, which due to different sizes and form make the surface not quite acceptable. In addition, sand particles are broken and become dust. Therefore, after a while, the entire volume of sand used comes into disrepair.

To avoid such problems, you need to buy special consumables. Most often they have artificial origin. The choice of a certain type depends on the two parameters depending on the type of work, the surface and the desired result:

- hardness;

- the size and shape of the particles.

A homemade sandblasting gun is good for home use, but for a large number of work it will not work. With artistic glass processing, it is also not very good, because Sand flies in all directions and to complete the work requires a large number of it. To reduce the abrasive consumption, you need to construct a closed sandblasting chamber.

How to mount a sandblasting chamber

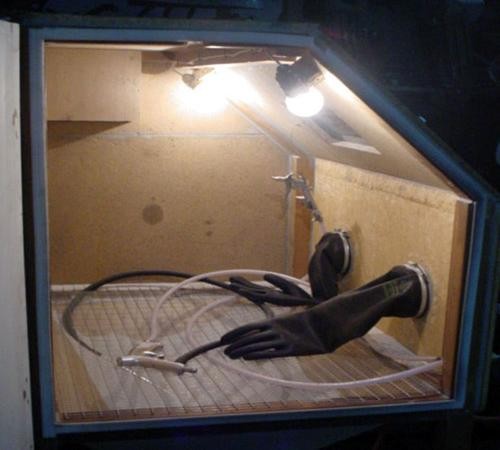

A homemade chamber will allow processing small items. It is a rectangular shape box, the frame of which is welded from metal corners and trimmed thin plywood. It is very convenient to place the camera on the table or come up with a special stand. In one of the long side of the drawer, you must make a small opening for the viewing window to be glazed.

In the same wall, where the window is equipped with a pair of round holes with a diameter of 10 cm. They will be needed in order to survey your hands inside the box and produce any actions there. In these slots, long gloves should be secured to protect hands. It is better to provide for the possibility of replacing them in the case of wear.

At the bottom of the box, fasten the wire grille, under which the arrangement of the chute leading to the tank for the collection of the sand used. Also in the wall it is necessary to provide a connector through which the air will be connected to the inside the sandblasting pistol. The hose by which sand will go, put in the tank with this material. Thus, a circulation will occur: the sand used enters the container, from which the hose follows the second round.

Inside the design it is necessary to provide lighting and ventilation. The latter is optional, but better if it is.

In one of the short sides, make a closing hatch. Through it, the part to be processed will be suited inward. To be able to process large length items in the chamber, it is better to equip the so-called loading windows from the sides and pick them up with a tarp cloth.

If there was a need to independently construct the sandblasting machine, reviews and recommendations on the Internet will help to better understand how to implement it.