Stone fence with their own hands Construction

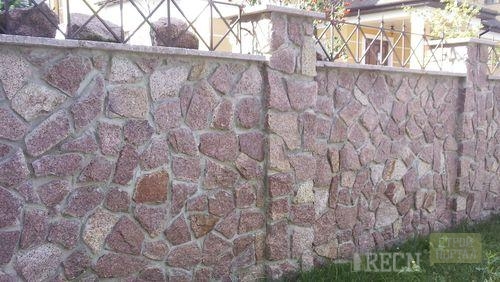

The fence of stone looks very respectable, aesthetic, beautiful. In addition, it is very durable, durable, reliable - real fortress.

Content

Types of stone fences

Material for a stone fence can be:

- cobblestone;

- pebbles;

- limestone;

- sandstone;

- booth;

- dolomite stone.

From the choice of material and design depends on and how there will be a design of a slaughter from stone.

Stages of building a fence from natural stone

It will be about how to make a fence of stone. Capital construction begins with the foundation. Fence from natural stone is no exception.

Foundation

1. Marking is performed.

2. Given the width of the column and the drainage depth, the trench is digging. It is usually its width from 400 to 500 mm, and the depth is from 600 to 800 mm.

3. In order for the finished construction to be no closer, the support columns are performed in several places in the form of glasses. In the place where the set of the gate is planned, the ribbon foundation is not interrupted.

4. Stacked fittings for bundle fence. In those places where the pillars will be installed, it is produced. If the gate is not planned to be done too heavy, then there are enough four metal rods with a diameter of 140 mm. It is important that the distance between the support pillars bothered with high accuracy.

5. Concreting is carried out by a continuous flow. The armature under the stone pillars is covered with concrete to a height of at least 20 mm.

6. Concrete is compacted, whether the method of plug, or with the help of a deep vibrator.

7. The surface of the foundation is aligned horizontally using the level or level.

8. Cover the foundation for a fence from a wild stone, as sometimes called natural stone, polyethylene, leave to stick 2-3 weeks. Periodically, it is watered with water.

Preparation of stone

Before proceeding to the construction of the fence, the natural stone needs to be processed. Wherein:

- the stone is more flat, having a straight angle, is selected on the poles;

- the front side of the fence is performed by stone in quality just below, and the inner part is from all the rest;

- the upper and lower edge of the natural stone makes smooth using a special hammer;

- vcE convexity on the front side of the butte stone also need to be touched.

Laying column

When erecting pillars, however, as already spans, use 3 types of masonry:

- butt - natural stone is used with incorrect forms. It is usually used for the inside;

- true - the stone has parallel sides;

- tree improved type. Here are all seams are parallel or perpendicular.

The laying of the slaughter of stone is not a very easy task, but quite perfect. It is only necessary to carefully and scrupulously perform all operations. First of all, he should stand smoothly. For this:

- connect the twine extreme poles;

- exhibit an angle of 90 degrees using a coal;

- on the surface of the foundation draw a straight;

- measure the distance between the opposite angles of the wild stone. It should be equal to the size of the part of the future pillar;

- a solution of 3 buckets of sand, 1 buckets of cement and 1/4 buckets of Cerazite glue cm11 are prepared. All this mixing, add 1/2 bucket of water and stirred again.

Now you need to arm the level and set the first angular stone, and then, consistently and the rest. In the height of the stones for a pillar can be different. Between the corners there will be free spaces and they must be fill. For this:

1. The space is measured by width;

2. There is a stone with a smaller width than a space on the size of the seam, and this is not more than 20 and at least 15 mm one way. The height should coincide with the corresponding size of one of the angular stones, in the extreme case of the required can be achieved, reaching 2 parts;

3. Filled in the seam solution: both from the outside and from the inside;

4. wait until it hardens and filling the solution into the inner space;

5. When it will freeze, styling the next row with the dressing of the seams is performed. Seam should not be placed on the seam, otherwise the work will be poor quality;

6. Permissible deviation in height: plus-minus 1 cm by 200 cm.

Span

Stone column, usually wider than the laying of the span. Therefore, it shifts relatively to the first evenly on both sides: external and internal. So:

- explained symmetrically stones from the opposite sides of the span;

- join the thread that will serve as a guide;

- stacked rows with mandatory dressing;

- to the upper line of the fence was smooth, stones from which the last row performs should be the same in height.

Shumov extending

Seams are two types: deep and shallow. With a deep extender, the impression of greater volume is created. To split seams thus need a tool:

It is necessary to break the seams after 3-4 after the end of the masonry, otherwise the solution will become very tight and the task will complicate:

- Flat-wire brush perform stripping stone and seams;

- perform rectangular grooves in the seams. Depth - 1-2 cm;

- the fence is washed using a foam and brush, a solution of 30-percent hydrochloric acid.

Artificial stone fences

Fences made of artificial stone are also very durable. The technology of their structures is slightly simpler, as it is not necessary to arrange a solid foundation. Forms and colors are the most different. The composition includes cement and special fillers, and visually this material resembles a natural stone, but the cost of such a fence will be much lower.

The way the fence of the decorative stone will look largely depends on the dye. Manufacturers payable by their reputation use high-quality dyes produced in Germany - Bayer. The color of the fence will not change for decades.

How to perform a finish of the fence of a stone?

Sometimes I want to somehow update the design of the fence: whether the old one is tired, or in order to hide the flaws that are made when it is erected. Suppose the fence is brick, with large irregularities. I will perfectly hide their corpus granite. Establish:

- facade primer is applied. Dry;

- special glue or sand-cement mixture is taken with the addition of plasticizer. Applied to the wall and on the surface of the stone;

- the stone is pressed against the wall very tight;

- we will extend the seams;

- wipe the surface.

It looks very nice in the finish, a combination of stone and structural plaster or bricks.