What to choose pipes for wells Plumbing

Autonomous water supply system - the choice of many owners of private houses. This solution becomes particularly relevant when, in principle, there is no possibility of connecting to a centralized line. The device of a modern durable well is quite complicated. One of the main elements of the system - pipes, to choosing a solid approach. What exactly to pay attention to, you will learn in this article.

Content

- Purpose of pipes when drilling a well

- Cuff Pipes for Well - Installation Technology

- Criteria for selection of pipes for wells

- Pipes for Wells - Materials

- Types and advantages of metal pipes

- Features of using asbestos-cement pipes

- Pros and cons of plastic pipes

- How best to connect pipes when drilling a well?

- What type of pipes to choose: pressure or non-bargain?

- Which diameter of the pipes to choose for a well?

- How to calculate water consumption?

- Conclusion

Purpose of pipes when drilling a well

To achieve a layer of water in the thickness of the soil, a rather laborious work is carried out - drilling wells. The main condition in carrying out this process is to protect the walls of the well from the destruction and the safety of water as clean as possible. For the implementation of the goals, pipes are used, each of which performs its task.

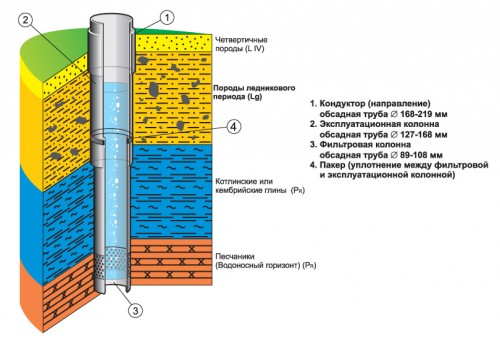

For the purpose of the pipe for the well there:

- casing - protect walls from collapse;

- operational - prevent water pollution.

Important! In order to save consumer money, modern manufacturers began to produce pipes performing two tasks at the same time. Therefore, it is even easier to buy pipes for the well.

Cuff Pipes for Well - Installation Technology

Performing the installation of casing pipes is a rather time-consuming process requiring special equipment. Installation is made as follows:

Important! The sizes of the casing are selected in accordance with the diameter and the size of the well, from which the cost of the climbing project will be directly dependent. Browse the cognitive video, in which the entire well design process is available sequentially, in stages.

Criteria for selection of pipes for wells

The well drilling is carried out individually for each situation. Before making the final choice and decide which pipe on the well is best suited in the conditions of your project, consider the following series of factors:

- drilling depth;

- diameter drilling;

- drilling work technology;

- sewage level;

- the structure of the soil.

Important! As is known, the structure of the soil in different parts is not identical and has mobility. Therefore, definitely decide in advance, from which layer of the soil you will produce water - the price of the pipe for the well will depend on it. To determine the state of the soil and the level of groundwater occurrence, specify this information from the nearest neighbors in the site, which have already encountered this task or attract profile specialists for engineering and geological surveys.

Pipes for Wells - Materials

The building materials market is literally filled with various assortment of pipes. Many options are suitable for the design of autonomous water intake systems. For example, to make pipes for wells, manufacturers use such materials:

Important! Each pipe made of these materials has its purpose and features, so pick up the universal version is unlikely to succeed. For example, a pipe for the pump pump will be one type, and for the decoration of the cluster - the other. But in principle, find a combination, affordable enough, if you correctly agree on previously all the details of the project and listen to the opinion of specialists.

Types and advantages of metal pipes

Metal pipes for wells are presented in several versions and use permanent demand among consumers. Positive responses have earned steel pipe due to a number of advantages, including:

- high design reliability indicator;

- durability - not less than 50 years;

- easy to clean;

- retains water clean;

- the ability to withstand heavy loads, given the insignificant thickness of the pipe walls - only 6 mm;

- resistance to mechanical damage.

In addition to pipes from ordinary steel, such varieties are presented on the market:

Among the significant drawbacks of metal products, such factors are noted:

- steel structures are quite expensive;

- with long-term contact of galvanized material with water, there is a possibility of water pollution with zinc oxide, which is unsafe for health;

- installation of enameled pipes without chipping is almost impossible, during which elements are rapidly corrosion;

- after some time, after installing pipes made of stainless steel in the water, rust particles can be detected.

Important! To eliminate almost all of the above problems, professionals recommend installing a household water filter during the immediate assembly of the design of equipment for water intake.

Features of using asbestos-cement pipes

Pipes from asbestoscement is the material that has long shown himself from the best side in the construction industry. They have long changed from the market with such structures from the metal, if not for one disadvantage - the fragility of the material.

Among the positive characteristics of asbestos-cement material are allocated as follows:

- low cost;

- corrosion resistance;

- unlimited operational period;

- chemical neutrality of the material.

Important! To ensure the strength of the structure, the walls of asbestos-cement structures make quite thick, that is, the diameter of the pipe for the well of this type will be large than from other materials. Consequently, the well intended for laying such pipes, brings into account this particularity.

Pros and cons of plastic pipes

Plastic pipes for wells have long established itself as a material that is inherent in a great combination of price and quality. In construction stores, the range of plastic pipes, suitable for the design of drilling, is presented by three types:

- PP - Polypropylene Pipes;

- NFCH - pipes from non-plasticized polyvinyl chloride;

- PND - Low Pressure Pipes from Polyethylene.

Important! Making the purchase of pipes, carefully follow that their destiny it is for drinking water.

Plastic pipes are distinguished by a number of excellent performance, among which are indisputable advantages:

- ease during transportation and installation;

- have a relatively low weight;

- do not be corrosive;

- absolutely safe for health;

- long-term period of operation - more than 50 years;

- high tightness indicator at the butt sections;

- resistance to mechanical damage;

- the ability to process pipes with chemicals used for the purpose of disinfection and regeneration of wells.

Important! A significant disadvantage of plastic pipes is distinguished by a low strength indicator, based on the requirements for this parameter directly for drilling wells. Therefore, PVC pipes for wells often apply when the drilling height does not exceed 60 meters. The main place of use of operational plastic pipes - casing steel columns.

How best to connect pipes when drilling a well?

If the well diameter is over 10 cm and is assumed to install a submersible pump, the casing will consist of segments that are usually 3-12 meters long.

Important! To understand which connection method is to choose, remember that the main task of the casing is preserving tightness.

There are 3 methods of compounds:

- Coupling thread, including fittings. This method is considered the most expensive due to the high degree of reliability. To ensure good tightness, a pipe with a thread for a well will be the most reasonable solution. But at the same time, consider that when using fittings, an internal useful well diameter may decrease, which will limit and select the pump.

- Welding connection method. A dubious way of designing joints, as the tightness of the welding seams will be directly dependent on the work of the welder. Also consider that welded seams on metal pipes are corrosion, which significantly reduces the service life. More acceptable is the use of such technology to arrange pipelines in open areas in order to detect destruction in a timely manner and stop it, without allowing an emergency.

- Installation of pipes in a squash is a method of connecting pipes through a sealing ring. This method is absolutely unreliable because you will not be able to monitor the quality of the installation of pipes, as well as there is a probability of drawdown when used.

Important! Of all the above, it is easy to conclude in favor of the only correct technology of the compound when the drilling well is arranged - the connection of pipes by carvings.

What type of pipes to choose: pressure or non-bargain?

To determine what type of pipes give preference, to start, find out what they happen:

- Non-perm - these are pipes that are used in conditions without pressure.

- Pressure is the material, the walls of which are withstanding high external and internal pressure.

Important! To arrange the casing columns, acquire exclusively pipes, since the pressure of the soil on the inner walls of the design is inevitable.

Which diameter of the pipes to choose for a well?

The diameter of the casing tube is calculated depending on the type of pump used. At the same time, if the water-space horizon has an increased dynamic and statistical water level, the pump in the casing is in suspended state.

Important! Information on these indicators is better to clarify in organizations carrying out well drilling.

To understand how to make the calculation correctly, we propose to consider the embodiment, where the water consumption is approximately 3 m3 / hour. For these purposes, the pump with a diameter of 75 mm is suitable.

To calculate the pipe diameter, spend the following calculations: 75 mm + 8 mm (the thickness of the pipe wall) +4 mm (the gap between the pipe and the pump) \u003d 87 mm.

Important! All casing pipes have standard sizes. Such standard dimensions of the diameter of the dumper pipes are most suitable for the obtained digit:

For a pump with a diameter of 102 mm, the calculation is carried out by the same method: 102 + 8 + 4 \u003d 114 is a suitable diameter of the pipe, but it is better to choose with a reserve - 127-133 mm.

Important! The optimal option is to be pipes made of steel with a diameter inside 10-15 cm, as well as PVC pipes with a diameter of 75-140 mm. Such pipes from wells are not taken out.

How to calculate water consumption?

Since the future consumption of water directly affects the principles of choosing different components of a private engineering system, we note separately the rules of calculation. To calculate water consumption, take a maximum consumption for an example with a fully open household crane - 0.7 m3 / hour.

Suppose the water at the same time consumes water:

- washer;

- crane in the kitchen;

- crane in the bathroom;

- watering lawn in the yard.

Important! The peak of water consumption is approximately 2.8 m3 / hour. At the same time, in a two-storey building, the average water consumption will be equal to 6-8 m3 / hour.

Conclusion

The process of installing autonomous water supply is a rather time-consuming, painstaking work, requiring significant cash investments and time. Before deciding on the drilling of the well, carefully read the rules of installation, the features of the adjacent territory, the assortment and quality of materials suitable for your project.