Steamproofing for the roof: selection features Insulation

The insulated roof of the house needs good vapor barrier, because the condensate, which is going to be in the thermally insulating layer, should evaporate into the surrounding space. Steampaullation for the roof can be made from many materials, about their views, features and characteristics we will tell in this article.

Content

Why do the roof vaporizion

In the rooms of residential buildings, the air has a certain humidity, besides, in such premises, it is almost always warm. Preheated water vapors, climbing up, condensed under the ceiling and in the underfloor space. The thermally insulating material that the roof is insulated, absorbs this moisture and accumulates it. In cold weather, water in the insulation freezes, in connection with which the material loses its useful properties and does not perform the functions for which it is intended. When the street becomes warmer, frozen moisture in the insulation pulls off and destroys it. As a result of several such cycles, the inner filling of the roof becomes unsuitable for operation. For example, if the humidity of the insulation increases only by 1%, heat losses are 32%. And if the humidity of the thermal insulation layer increases by 5%, its properties are worse.

In addition to the destruction of the insulation, the moisture is destructive and other parts of the roofing structure, for example, on wooden and metal elements. Wet wood boosts, moldsheet and flies, and metal rust. To avoid the negative effect of steam, the roof should be protected with the help of special materials that will prevent the condensation of water in the roofing cake.

Tips for choosing vapor barrier for roofing

Before you buy vapor insulation for the roof, you need to consider several nuances:

- the temperature zone in which the construction is located;

- purpose of the roof (its suitability for operation);

- roofing cake design.

Consider what the requirements should be a qualitatively performed vapor insulation layer:

- When choosing a material, first of all, it is worth paying attention to its tightness. This is the most important characteristic for a similar type of funds. In addition, during the installation of vaporizolation, its individual elements need to be very thoroughly glued or welded, because even through the smallest moisture gaps, it will break inside the roof.

- It is desirable that a steam-insulating layer has created threats in the event of a fire. For this, the material is placed between the insulation layer and the profiled sheet.

- The lower layer of roofing pie can be made from non-combustible materials, in such a case, vaporizolation is paired between two layers of insulation.

- So that the roof refractory was higher, the insulation is desirable to mount a mechanically.

- In those places where the roof touches the walls of the building, the steam-insulating film wrapped on the wall so that its edge went beyond the limits of the insulation. Then the membrane is glued to the wall and additionally fixed with galvanized rails.

Types of materials for steam barrier

Not so long ago, ruberoid and pergamine were considered the most popular means for hydro and vaporizolation. Now the construction market offers many more new and high-quality materials with improved technical characteristics. Ruberoid is now used in construction, but the greatest plus is considered a low price. However, in order to save it, it is advisable to apply for finishing of roofs of non-residential buildings, such as economic buildings or garages. In addition, similar toes are better to use not as the main vapor and hydrobarrier, but as an additional layer to other, more efficient materials.

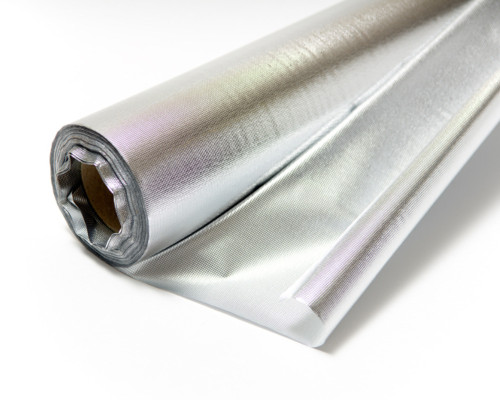

Worth the question of which vapor barrier for the roof is better, it is worth understanding all its kinds. The newest materials for vapor barrier roof include multilayer polymer membranes and films. Their main advantages are high strength, good performance properties, durability and simplicity of installation. Created on the basis of polypropylene and polyethylene, vapor barrier films have a reinforcing layer.

Separate parts of the film are connected to each other by special technology - by heating the seams. This method makes it possible to create a solid, almost seamless and waterproof coating. In addition, this method is implemented in a short time, and the result is high quality.

Concrete roofs of a flat configuration are often steam insulated with bitumen membranes, which are fixed on the working base by heating and subsequent gluing to the surface. The advantage of bituminous membranes are their high elasticity, thanks to which the film quickly restores its initial view of the stones and deflection sites. It is worth noting that even in places of the sheets of sheets, bituminous membranes perfectly protect the structure from moisture. The disadvantages of the material include high weight.

Another popular vapor insulation agent is considered non-perforated films that are used in the finishing of flat and pitched roofs. There are several types of such films:

- reinforced fabrics made of polymers;

- reinforced laminated films equipped with an aluminum foil screen. The purpose of the foil layer is the reflection of warm air inside the residential rooms.

Films with a laminated surface are mounted directly on the insulation layer, but a gap of 5-6 cm should be respected between such a film and internal covering, which is necessary for the penetration of air and weathering of moisture from the roof. The reinforced films have different density and level of flammability, they also differ in the degree of resistance to ultraviolet radiation. But all similar materials combine such qualities as environmental friendliness, safety, resistance to moisture, molding and formation of rot.

Steam barrier for a flat roof of the house should have good resistant to high temperatures, since the roofs of such configuration are prone severely hot under the sunny beams. For folding roofs, for the roofs decorated with metal tile or metal profile, vapor insulation films should be selected with special care.

The reflective surface films are used when strong air flows circulate in the undercase space, as well as in the case when it is required to maintain high heat in the room. Such membranes are often used in baths and saunas.

For the operated roofs, for example, for roofs of mansard floors, vapor insulation with good strength characteristics should be selected.

Anti-condensate films are another popular material on the modern construction market. Such membranes from a special porous fabric are made, the inner side of which has an adsorbing layer. This layer is designed to absorb condensate, so that he will subsequently evaporate it into the surrounding space. An anti-condensate film when installing needs to be laid out to the outside, so that it in contact with the air.

Among modern building materials, breathing membranes were gaining great popularity: diffusion and superdiffusion. Such films are distinguished by a very small thickness, which does not exceed 0.2 mm, as well as low weight. Despite the characteristics described above, the membranes have good strength and can serve for quite a long time, from 30 to 50 years. As a rule, breathing membranes consist of 2 or 3 layers. Two-layer materials are a combination of polypropylene tissue and polyethylene laminate. The three-layer "pie" consists of a mesh polypropylene coated with a plastic film on both sides.

Superdiffusion membranes can be mounted directly on the insulation layer, so that the design of the roofing pie will be much thinner than when using other vaporizolizing agents. In the event that the roof is insulated with a mineral wool, a similar membrane will additionally protect the construction of the wind and allow heat to stay in the rooms. Superdiffusional type membranes are used for hard and soft roofs. Of course, the price of such steam barrier for the roof will be quite high, but the material will last for a very long time.

Diffusion films have a slightly smaller indicators of vapor permeability than superdiffusion membranes. When installing diffusion material, ventilation gaps must be provided, through which condensate will evaporate from roofing pie. Such membranes are made of polypropylene, polyethylene, cellulose or polyester. The popular diffusion membrane today is the material titled "Izospan". Since it is very often used in construction, we will tell about its features and varieties in more detail.

Steamproofing for the roof of the isospan

The ISOSPU is referred to as a new generation vapor barrier means. Such a material has excellent performance and perfectly protects the roof design from condensing moisture. Izospan laying is carried out on the carrier elements of the frame, laying sheets from the inside of the heat insulating layer. It is permissible to fix the material on the draft trim using an ordinary building stapler. The process of such a finish is carried out quite quickly.

The main purpose of the isospana is to hold heat inside the structure, as well as the protection of the heating layer of the roof from the penetration of moisture. The structure of vaporizolation is such that one side of it is covered with a rough material that absorbs condensate and allows it to evaporate on a natural way. Thanks to the isyospan, the rooftop does not develop fungi and mold, wooden and metal structures are not destroyed by moisture.

The main purpose of the isospana is to hold heat inside the structure, as well as the protection of the heating layer of the roof from the penetration of moisture. The structure of vaporizolation is such that one side of it is covered with a rough material that absorbs condensate and allows it to evaporate on a natural way. Thanks to the isyospan, the rooftop does not develop fungi and mold, wooden and metal structures are not destroyed by moisture.

There are 14 types of isospan, and each type of material is characterized by technical characteristics and purpose. Tell in more detail in this matter. Class A isoSPan combines 4 types of vapor-permeable films that have different strength, density and ability to skip steam. There is also one of the material and one more characteristic - resistance to the effects of solar radiation. As for the Class A isospan, all of its varieties, this indicator is the same and equal to about 4 months. When buying a vapor barrier to this indicator, it is worth paying attention to, since during construction work the membrane is to be in an open-air. Consider more, which is a vapor insulation material of this type:

- Izospan A is a thin two-layer film, the main purpose of which is to protect the roof, including its insulation layer, from the negative effect of weather factors: water, moisture, wind. This material also prevents the accumulation of the underpants condensate in the insulation, thereby extending its service life. Such vaporizolation is most often used in the finishing of the pitched roofs of any configuration, the material from the outer side of the insulation layer is mounted. This kind of isospan has the highest steam-capacity, which is 3000 g / m² / day. Among the backs of the material, it is possible to name the features of its installation, which suggest an additional construction of the crate to create a ventilation space. The lamp is performed from the counterrelic, this process takes a certain time and requires additional cash investments.

- Izospan AS, in contrast to the previous two-layer membrane, consists of 3 layers. The purpose of the material is to protect the roof and walls from moisture and water vapor entering both the outside of the structure and inside the residential premises. This Type of Isyospan is considered the most durable among its analogues, it also has the longest operation. The vapor permeability of the material is 1000 g / m² / day. Unlike the type described above, the IOSPAP AS can be laid directly on the layer of insulation. To install it, you do not need to make an additional crate, which allows you to save time, money, materials and physical efforts.

- Izospan AM is a three-layer membrane that performs the function of water and windproof roofs and buildings from the negative impact of the environment. To install such a material, the creation of a ventilation gap is not required, the film is laid directly on the insulation layer. The vapor permeability of this type of isospan is lower than that of similar materials of the same group, it is 880 g / m² / day. This membrane is universal and can be used in buildings and buildings of any destination.

- The isospan and with flame retardant additives according to its technical characteristics is almost no different from the Isyospan AS, but this material has refractory properties. It can be used where welding or other types of work related to fire will be carried out. The vapor permeability of such isospan is 1550 g / m² / day.

The second class of vapor insulation materials is represented by the Izospan B, C, D and DM. These types of isospan are cheaper and used in a wide variety of conditions. Such materials have a two-layer structure: one layer is made of a smooth water-repellent film, and the second is made of rough material. The rough surface absorbs condensate, which is subsequently displayed in the environment with a natural way.

Putting the isospan of these types in such a way that the grungy layer is directed to the outside - where moisture can come from under the roof. The guideline film should be directed toward the insulation to isolate it from the negative external environment.

Among these stamps is the greatest universality of the isospan C, which is applied not only as a paosolation of the roof, but also as water waterproofing. Such material can be stacked on any surface: concrete, crushed stone, soil, sand.

The characteristic features of the grades D and Dm are increased resistance to ultraviolet action, as well as good strength. This elegant is often used as a temporary roof, since it can easily transfer the snow load and long exposure to the Sun. This temporary roof can be used about 3-4 months, after which the vapor insulation layer will be required to close with another material.

Relatively new materials on the construction market are RS and Izospan RM. Such films have increased strength, since they are reinforced with a special grid of polypropylene.

Class F isoPan is also represented by 4 varieties of vapor insulation materials: FS, FB, FX, FD films. Such vaporizolation not only protects the roof from condensate, but also is capable of reflecting infrared radiation than the thermal insulating properties of the material are caused. A similar layer is an additional roof insulation, allowing you to save on the housing heating. The Izospan of this group does not have a steamropropus ability, it is absolutely sealed, does not let any moisture, nor the air. Because of the above characteristics, the material is advisable to apply in those buildings where there is artificially forced ventilation. By the way, such an elevation is suitable not only for the roof finish, it is also used as a reflective film in a warm floor system, and sometimes laid behind heating wall radiators as a reflective screen.

In this group of materials, the fd FD is the most durable. The second place of strength occupies the FB isesin, and the FX class material has the lowest strength characteristics. The FX FX is made of foamed polyethylene, the thickness of which ranges from 2 to 5 mm. On the one hand, polyethylene is coated with reflective metallized film. FB Česospin is made from kraft paper, which causes a metallized lavsan to one of the sides.

All species of the Class F are the same thermal radiation coefficient, which is 90%.

Features of laying roofing vaporizolation

Regardless of whether vaporizolation onto the pitched roof or on the roof of a flat type, this work can be carried out only after the insulating layer is performed. The approximate scheme of the roof vapor insulation can be found on the Internet, we will give some subtleties of this process:

- Separate elements of vapor barrier material can be laid in any direction: horizontal or vertical.

- In case it is decided to mount sheets vertically, the laying process should be started from the top of the roof.

- Separate parts of the vaporizolation membrane should be laid, which should exceed 10 cm. The resulting seams need to be carefully smoke with high-quality adhesive tape. The tape width must also be at least 10 cm.

- If a double-sided tape is used to cross the seams, it should be first fixed on the bottom sheet, then remove the protective film and glue the top sheet of the vaporizolation membrane to the tape.

- If the vaporizolation is carried out along the construction rafter and without the use of the draft heaters, the nestling of the material should be carried out directly at the rafted level, in the same places the vapor barrier should be recorded.

- For mounting, the membrane uses stainless galvanized nails or staples that are driven by a construction stapler.

- If the roof has a bias of more than 30 °, or if the sheets of the insulation are loosely adjacent to each other, the locations of the stakes of vaporizolation sheets are desirable to further strengthen with special clamping straps.

- If the water pipes are passing through the roof, the booster membrane in places of its contact with the pipes should be wrapped down, wrap around the pipe and thoroughly flush the tape.

- If the type of material involves the creation of airspace for evaporation of moisture, you can make it with thin wooden planks. Such bars must be soaked with all the necessary antiseptics. Planks should be approximately 50 cm from each other. In principle, some types of membranes can be laid directly on the insulation, without creating a frame, but such an air corridor will be useful in any case, for example, to lay communications.

Roof vaporizolation device: Useful Tips

- When installing a vaporizolation membrane, you need to closely monitor the quality of the joints. If in any place they will be poorly cursed, all efforts from the work done will gradually come to no, because moisture will penetrate through a weak point inside the roofing pie destroying it at all levels.

- The tape for the sizing should not be 10 cm, otherwise it will simply come off.

- When finishing places around windows, hatches and other openings, it is necessary to provide a deformation supply, since any building after the construction is somewhat settled. The deformation supply involves leaving the folds of the material of 2-3 cm wide.

- The vaporizolation membrane laid around the perimeter of the attic windows should be protected from the inside with a special finish.

- A pair-protective material should not envelop the roof rafters, otherwise the condensate will fall on wood and lead to it.

- Fix the membrane on rough surfaces, for example, on a brickwork, unwranched wood, slag blocks, can be used with adhesive compositions on polyurethane, acrylic or rubber-based basis.

- The adhesive tapes for the processing of the seams are different, but it is not recommended to use the material on a polyurethane or butyl-rubber-based basis, as it does not have sufficient adhesion and after a while, it will be quite simply from the surface.