Stairs with their own hand Ladder

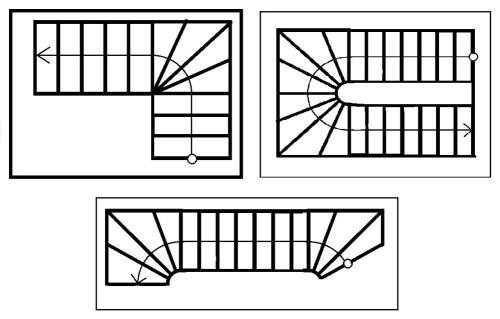

In some homes it will be quite appropriate to look a staircase with a turn. Usually this option is chosen if for some reason it is impossible to install a single-sample design. In this case, the rise is turned on some degrees (90 or 180). For the manufacture of a staircase with turning with their own hands, wood or metal is usually used. From what material will be applied, the parameters of the future design and the complexity of its installation are dependent.

Content

We select material

It is best for the manufacture of a staircase to the second floor with a turn to use still wood. The fact is that running steps during installation in any case will have to be corrected, no matter how accurately, the preliminary calculation and measurements were performed. If another material is used, for example, a stone, it will not work like this adjustment. Wood without problems allows you to eliminate any deviations and inaccuracies of installation, and this can be done almost at any stage of the manufacture of the stairs.

Today, you can find billets and templates just for wooden stairs. They allow you to significantly alleviate the installation process itself. But this does not mean that at the same time it will not be necessary to customize the design for specific sizes. In addition, such blanks are not always made of high-quality material, although the price of the products themselves is often quite high.

The basic details stairs is quite possible to do on their own, but it will take to pick up the material and components correctly. Missing items can be purchased in stores. For example, you can buy ready-made decorative balusters. After production of such details would have taken a lot of time.

Now analyze what materials will be required for the stairs of wood with a twist. First of all, as mentioned above, it is wood. It is best to use for this purpose arrays beech or oak. But these rocks are quite expensive. Therefore it is possible to give preference to larch, pine or maple. In either case, the wood must be properly dried. Otherwise the string eventually lose its shape, and the stairs are unpleasant squeak, which will require additional repair costs.

The width of the boards to mounting structure should be at least 55 mm. Also needed thick pieces of wood at least 40 mm. You need to buy fasteners for structures (eg, screws, screws, screws). Useful metal corners and construction adhesive.

It is said that in contrast to the wooden structures, metal stairs with a turn are used quite rarely. Since their installation is quite complex.

The choice of the support structure

The supporting structure is a flight of stairs known more as kosour simply needed for the construction of any ladder. For construction with swivel steps will need 4 to 6 stringers. It depends on the number of flights and the size of the angle of rotation:

If only two marches, then to consolidate these beams will first need to install one central pillar, which serves a decorative element, as well as the basis for fixing stringers.

If three marches, the load-bearing pillars need to have not one, but two. To do this, select the support section with a minimum of 100 to 100 mm. The height of the column depends on what kind of turning staircase will be installed.

Calculating turning staircase

In order to do the calculation, you need to know some important parameters. In particular, it is necessary to calculate the width of the march steps dimensions and turning radius. In addition, you will need to know the length of the horizontal projection of the plane of the march. It is measured from the last step to the top of the rotation angle.

To calculate the width of the steps taken as a basis the average line. And all the steps in one march must have the same width.

The above parameters can be calculated in different ways. For example, special formulas apply. But since the calculations are quite complicated, this method will be unacceptable for some people. Alternatively, you can use a graphic method. It is he will be discussed below.

Required calculations

Staircase with a rotation of 180 degrees

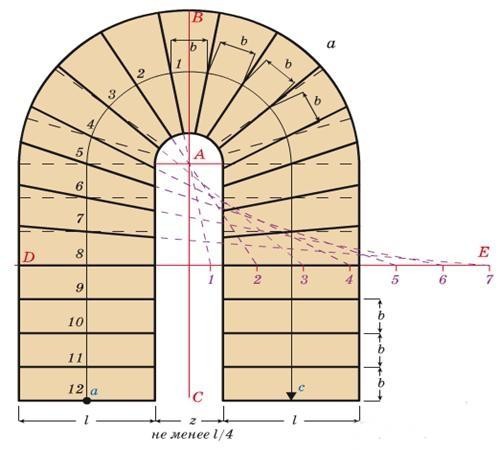

So how to calculate the stairs with a turn? Consider stages:

- First of all, you need to take a sheet of millimeter paper and mark the place on it, where the bend center will be (let it be point a), which coincides with the radius of the inner side of the future staircase.

- In addition, it is necessary to understand how much the steps will be made. Usually they are built as much as possible so that the stairs it is more convenient to rise. For example, you have chosen seven such steps. Mark them on the plan. Then, through the beginning of the next stage, they watched directly (we denote it as DE).

- Direct, indicated on the plan as AB, divides the staircase to the left and right equal side. The middle of the march must be denoted in the form of a curve. On this curve from direct AB, set aside a plot that is equal to half the width usually steps.

- From the found point (we denote it as point 1) We carry out a segment equal to the width of the step. From the resulting point again, postpone the segment, as described slightly above (we denote it as point 2).

- So you have to get around seven points. After that, through points 1 and the bend center (point A), outlined a line that intersects with a previously designated DE line.

- Another line must be carried out through points 2 and A.. In the same way we find the values \u200b\u200bon the DE line from the remaining 5 points.

- Lines that connect some identical points marked by numbers will determine the future geometry of the steps.

Calculations of the other half of the staircase (parts with running steps) are made in a similar way. You can calculate almost any rotary staircases described by the method, which you are seeing below.

Staircase with a rotation of 90 degrees

At the calculation of this turning staircase, a lot in common with the previous one:

- Similarly, first is the bend center (we denote as point a). After that, through it is straight (we denote it as AC).

- Next you need to decide how the steps will be located. Here are two options: or direct divides the angular step into two equal parts or two steps are adjacent to the line with their edges. In both options, there is a direct AC. When choosing a second method, you need to draw a curve on which equal width of the segments of the segment should be postponed.

- Next, you should define the number of running steps. If they are 4 steps on the turn, then through the end of the fourth of them you need to spend a straight line, which in the diagram we denote as EB. Moreover, the point B here is a point of intersection of two direct: EB and CA.

- After that, from the point of the center of the bend, set aside the arbitrary segment of the AD, on which three points are noted so that the first segment is equal to two parts, the second - three parts, and the third one. Here, "one piece" is nothing but an arbitrary segment equal to one conditional unit of measurement.

- After that, it is necessary to connect the end of the third segment with a point B. In addition, from the beginning and the end of the second segment you need to hold the line to the intersection with AB. Moreover, they must be parallel to the segment made at the previous step.

- The points that turned out on the AB plot are connected to the beginning and end of the third segment. The obtained lines determine the configuration of running steps.

Mounting order

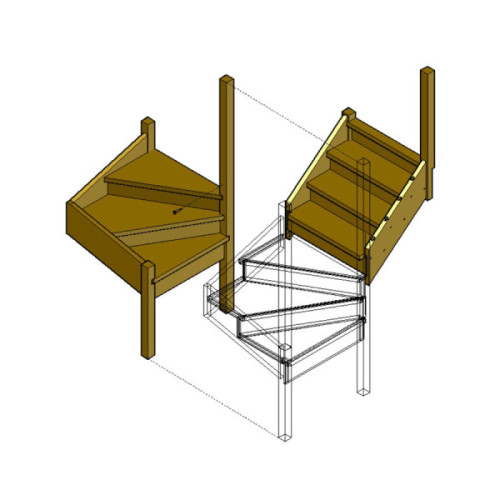

First of all, it must be said that it will be difficult to make a staircase with a turn with your own hands. At least because the design itself weighs relatively quite. Therefore, it is recommended to enlist the assistant, after which you can start making.

If the staircase has only one turn, respectively, in its design there are two march of different lengths. In a long march, eight steps are made, and the upper end ends where the site of the next floor begins. In a short march, only three steps. In addition, there are three running steps in the design, which are rotated by 30 degrees.

Procedure for conducting work:

- Start the manufacture of such a staircase is best with the mounting of the Kosomrov. First, a template is made in the form of a rectangular triangle. For convenience, it is fixed on the rail guide. Next Kosur is placed, after which it is cut with a circular. In order for the design to have sufficient strength, the width of the thinnest part must be at least 160 mm.

- After that, you can start the installation of the support pillar, in which the grooves must be done to insert the cosomers. In the corner, they mount a support that will fix Kosur near the wall. By the way, this reference design will be the basis for the installation of running steps. As for the upper ends of the cosomov, they should be fixed with metal corners.

- For the manufacture of running steps, you will need 90x90x4 boards. As already mentioned above, there will be three steps all. For their manufacture, the board is divided into three parts in such a way that the markup lines come out of one corner.

- When the steps are cut, they are carefully customized along the length. Next, they are covered by several layers of varnish.

- To fasten the running steps, it is necessary to cut grooves in the post, which should be slightly less than the thickness of the boards inserted into them. It reliably fixes the steps on the inside of the staircase. From the outside, it is necessary to make a refinement of support. This is necessary in order to postpone the steps.

- When straight steps are ready, they should be fixed in their place long self-draws. And the heads of the fasteners themselves need to drown. In order for the protruding angle of the run-down step is not noticeable, the march must be equipped directly on the tutor. So that you can mount the support column, the end of the tutor is trimmed at right angles.

- When running steps will be ready, you can install the railing. By the way, the balasins are sometimes attached from the bottom through the step by self-drawing, but this method is undesirable, because It can not be called reliable. For this purpose, wooden rods are best suited for the wickers. So, in the steps, you first need to make round holes with a diameter of a bit less dimensions of the wanks. After that, the holes are filled with adhesive mortar. Such holes are also made in the balusters, but there is one very important requirement: they must be made strictly in the center and vertically.

- Next, between the first and second post, it is necessary to pull the rope that serves as auxiliary tool when the railing tilt of the angle of inclination.

- Next, on these labels should be cut up the tops of the racks. For fixing the handrail, you can use long screws. The places of their attachment need to be hidden by putty.

On this work on the construction of the stairs can be considered completed. As you can see, there is nothing complicated.

Staircase with a turn: photo