Automatic gate with your own hands Useful advice

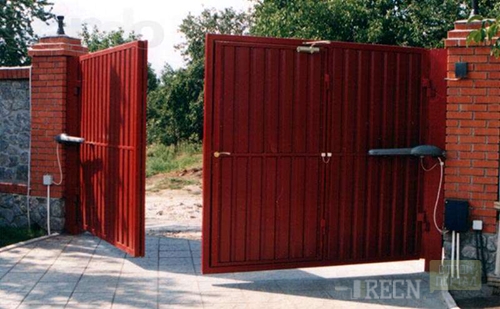

The gate is the first to pay attention to the entrance to the courtyard. They should be not only beautiful, but also easy to use. Why not make the gate with your own hands? So you can embody all your wishes without a long expectation of making and unnecessary waste.

Content

Types of gate

- Skump.

- Swing.

Retractable gates are called so because the door canvas rolled to the side. Outbreakdowns of the gate open, depending on the execution, either inside or out. Each of these types has its pros and cons. For example, at the opening gate area on which their movement is performed, empty.

Retractable gates "shift" aside when opening, which allows the use of "saved" space. The only minus is that the electric drive mounted on the gate requires periodic maintenance.

Principle of operation of a rollback gate

The operation of the retracting gate system is based on the movement of the door leaf on the rollers, which are installed on the hard foundation. Movement is carried out along a rigid guide, which is tied to the fence.

Depending on the weight of the door, for easy movement on the guide, up to 8 rollers can be installed on the design. Special rubber or other polymer material can be applied to the surface of the rollers. The closed bearing is mounted in the roller housing. In such a bearing there is a sufficient amount of lubricant, which is enough for all the time of its service. To ensure the protection of roller nodes from precipitation or external mechanical damage, they are mounted inside a square guide.

Provided that the sliding door is operated under normal conditions, in compliance with the rules of operation and maintenance, life cycle of an average of 50,000 full operating cycles - open / close. The gate of this type do not require special maintenance. For example, there is no need to grease them, since all the details provided it is still in production.

A typical set of sliding doors

- door leaf;

- roller trolley - 2 pcs;

- ro truck - 1 unit;

- guide - 1 pc;

- a set of upper support rollers;

- the end cap for the guide;

- catchers.

Minus the sliding gate - required free space for movement of the door leaf along the stationary fence. Sliding system can be equipped with automatic control or can work only in manual mode.

installation Procedure

1. Install the gate begins with the installation of support pillars. The supports used mainly for steel pipes. Then you can decorate them in accordance with the surrounding decor. Also pipes can be used as a channel, and so on concrete pillars. Pit for mounting pillar should be less than 1 meter. Established post not just dig in, it should be concreted.

2. Setting the foundation for sliding gates. For its production need № channel 20 (wall height) and the construction fittings 14 mm in diameter. Armature cut into rods of 1 m length and is fixed on the sill by welding. Fundam excavated depth 1.5 and 40 cm wide. It is poured concrete and laid up channel shelf. When laying channel, mandatory use level. It is important that sill regiment was exhibited in exact accordance with the road surface and lying horizontally.

3. Production of door frame. For its production traditionally used rectangular tube section 60 * 30, but actually allowed to use any available material, such as a round tube or corner.

4. After welding, the main frame, it is necessary to strengthen, i.e. implement weld filling. For the filling, you can also apply a small area, bar and so on. The filling is necessary to stiffen the structure. Since the entire finished surface of the structure to remove scale, degrease, primer is applied, preferably in two layers. For the final painting is desirable application of alkyd paints for exterior use.

5. After the filling is installed and the frame has gained rigidity, you can proceed to its trim.

6. As the foundation is ready, the rollers set the rollers of the sliding gate and immediately put on them a protective pipe. All the resulting design is set by level. Then the supports of the roller carts "stick" with welding to the surface of the schuleler. After checking the correctness of the consolidation, the outlined connections are finally welded.

7. Installation of the gate frame is also carried out by level and plumb. Everything else, namely the cattles, can already be recorded "at the place."

Advantages of swollen gates

Swing gates are also widely represented on the market. This design finds its application if there is no space for the installation of the sliding system.

Design of swollen gates

- Gate sash.

- Support poles.

- Shut-off devices.

The undoubted advantages of such a gate include low laboriousness of manufacturing and installation, ease of maintenance and long service life. Please note that in the winter season in front of them, it is necessary to constantly remove snow, otherwise they will simply do not open, especially it concerns automatic opening.

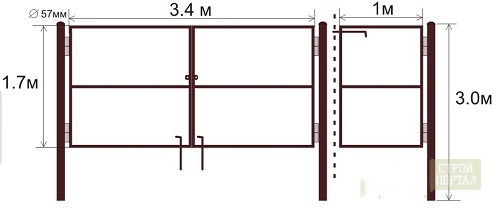

Installing a swing door

- As in the case of a rollback gate, all works start with the installation of support pillars. Immediately note, the depth of their installation is at least 1 meter and they must be concreted necessarily. You can use a square or round, cross section of at least 100 mm as pillars.

- Preparation of the frame. In order to use a square or rectangular tube with one of the sides of 50 mm, allow 50 * 25, or 50 * 50. Frame, depending on your wish, may be rectangular or square. As filling, you can breed the pipes of a smaller diameter or any other metal. Wired elements will ensure rigidity and become the basis for the subsequent sheat. Then the constipation is installed.

- After the end of the welding work, all the seams and the nearby zone should be cleared of the scale and splashes of metal. From the surface of the entire finished design, remove scale, degrease and apply primer into two layers. For final color, it is desirable to use alkyd paints for outdoor work.

- After the concrete was standing out, and the gate sash was dried, you can start the installation.

- The racks are welded with a loop, on the gate, respectively, their response parts.

In principle, that's all. The hung gate is left in a closed position for 10-12 hours.

The described assembly principle is quite suitable for both gates in open places and for and automatic garage gates.

Latest barcode - installation of locking automation.

Types of locking mechanisms

- Linear automation. It transmits an effort to open / lock the doors through a worm gearbox.

- The drive that transmits effort through the lever system.

- To hide an automatic drive, there are systems for transmitting efforts in the premium space, which must be prepared in advance.

The drive for the automatic gate of any type there are different types and prices, but before it acquisitions it is best to get advice from specialists in this area.