How to build a staircase for giving with your own hands. Wooden staircase - master class Ladder

Today, you can rarely see a modern one-storey country house. As a rule, cottages and cottages make two-, three- and even four-story. And it is quite logical that such a structure cannot do without a staircase, or even two.

Content

The most elementary decision will be to order the manufacture of stairs from professionals - a construction company or a private wizard. The second option is to buy a blank for a wooden staircase with ready-made elements and assemble it in place. If there is an opportunity, it is better to do so. However, if you have time, desire and skills, you can make a wooden staircase with your own hands. Today we describe in detail how and from what you can build a high-quality staircase for a private house.

Design features

Types of stairs

The choice of the design of the stairs depends on the free space that is planned to be used for the construction. Also playing the location, configuration, lift and, of course, the aesthetic preferences of the owner of the house.

Wooden stairs are marching or screw type:

- Marsemen - the most common type consisting of "staircases", that is, steps and small sites, which are called marchs.

- Screws are usually used in a small space or to save space. But some prefer the screw stairs by the Marsev because of aesthetic considerations. This type is distinguished by a pleasant appearance and sophistication. In fashionable architectural journals, photos of wooden stairs are a screw character. Despite the low functionality, many people set them. However, it is worth remembering that only one person can go down on such a design. Furniture to the second floor will also be difficult. If you do not have experience in the joinery, you should not start with the construction of the screw staircase - even the smallest error in the calculations can lead to deposits.

Materials

How to make a wooden staircase durable and durable? Take advantage of the following tips for the choice of building materials:

- Kososor and Active - Wooden Bar 50 * 250 mm. If the design of the staircase allows, you can take a minimum width of 150 mm.

- Precade - wooden beams with a minimum thickness of 25 mm. The greasy, the better.

- Shorty - Wooden beams with a thickness of 30-40 mm. You can buy identical beams for concerns and coming.

- Handrails, Balyasitsa - Better to purchase finished products. Independent manufacture requires professional skills and special turning equipment.

Device staircase

Any staircase regardless of the type consists of several mandatory elements:

- Kosur - carrying element, beam, supporting steps and preceptive. Located below and takes all the load.

- The string is the supporting element with special notches for the establishment of steps. If the staircase is one side leans to the wall, the string is applied only from one side if the staircase is "clamped" between the walls - from two. Unlike the Kooowa, the string is not intended for large loads.

- Steps - beams consisting of horizontal projected and vertical risers. The risers are performed both aesthetic and reference function. It is permissible to manufacture wooden stairs without risers, but in this case they will be less durable.

- Railings - consist of baluster and handrails. May have a variety of forms and sizes depending on the preferences of the customer.

Before you take for the construction of the stairs, you need to make careful calculations and perform a detailed drawing of the future design. If you have experience in drawing, you can easily cope with this task. If not - use the special computer program to create architectural forms. You can also contact a construction company or a company specializing in the design of stairs.

How to make an accurate calculation

- Determine the required number of steps and the height of the riser. To do this, find out the height of the future staircase. To do this, measure the distance from the bottom point on the first floor to the top point on the second floor.

For example, height from floor to ceiling 250 cm. Inter-storey coating (floor thickness on the second floor) is 35 cm. Total: 250 + 35 \u003d 285 cm.

Make calculations should be based on the height of the riser. As a rule, this is a standard size that makes up 15.2-19.7 cm. The average rate of 17 cm.

Simple formula for calculation:

The height of the stairs / the size of the riser \u003d the number of steps;

285/17=16,76.

Since the result was not entire, rounded it into the biggest side.

TOTAL: 17 steps.

To the risers were even along the entire length of the stairs, divide the height of the stairs to the number of steps:

285/17 \u003d 16.76 cm.

As a result, 17 identical steps with a riser of 16.7 cm were obtained.

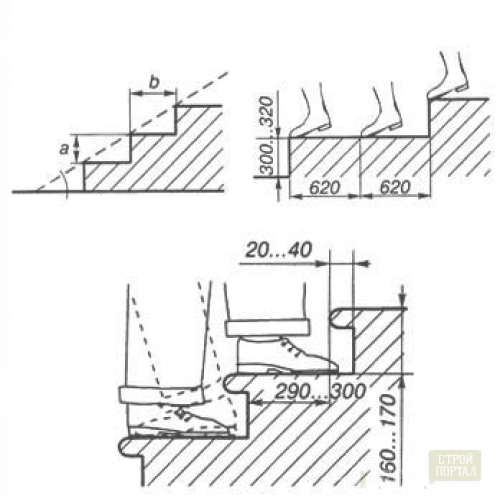

- Determine the width of the sticky. Standard parameters for this element from 22 cm to 40 cm. To accurately calculate several formulas:

2a + b \u003d 64 cm;

a + b \u003d 47 cm;

a - the size of the risk;

b - disposal.

Calculations on the first formula:

2a + 16,7 \u003d 64

64-16,7=47,3

47,3/2=23,65

23.65 cm may be too small for sticking, so you can make calculations on the second formula:

47-16,7= 30,3

30.3 cm is quite suitable for comfortable and reliable sticky. Round the indicator up to 30 cm for greater convenience.

- Determine the width of the march of the future staircase. There are no strict criteria for this indicator, but the number of spans directly depends on the location of the stairs. Conditionally allowable comfortable minimum for a march width is 80 cm. But the optimal version is from 100 cm to 140 cm. There is a slight tip using which you can build a harmonious and beautiful design - the width of the staircase march is a multiple sticky width. For a staircase from this example, it will be 60, 90, 120, 160.

- Calculate the length of the stairs by the formula:

Number of steps * width sticking \u003d ladder length

30*16=480

Why 16, and not 17 steps - the last step is not necessary to take into account, because It will merge with the second floor floor.

4.8 m - an impressive length that will take a lot of space. Therefore, if the space does not allow you to build a straight staircase with one march, you will have to agree to the manufacture of a wooden staircase with several marches and a turn. To calculate the measurements of such a staircase, it is better to use the computer program or services of a specialist.

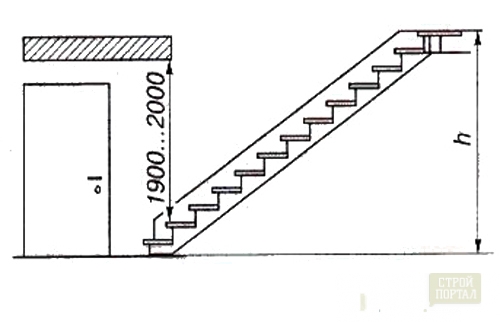

- Calculate the height of the lumen over the steps. When calculating, follow the main rule - the distance from each step to the ceiling must be at least 195 cm.

Installation and installation of stairs

Finally, materials are purchased, the calculations are made, the drawing is ready. You can proceed to the construction of a wooden staircase for home.

Installation of Kososorov and Testa

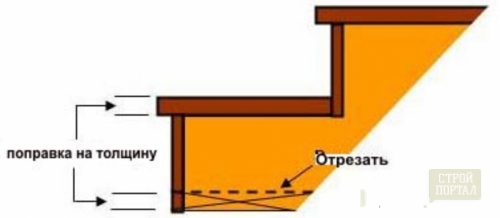

- End of beam purchased for cocheurs, cut down in accordance with the length of the stairs. From the bottom part cut off the thickness of the sticky.

- Cut out openings for steps. To do this, it should be noted the width of the sticking and the height of the opponse, take away 2-4 cm. For convenience, use the construction kit and a pencil to mark the beam. Dispose the extra pieces of the jigsaw or saw.

- Attach Kosor to the place of the future stairs. The upper end should come into contact with the overlap, the bottom - to rest in the floor. Check that the strokes are strictly horizontal. For the stairs, you need at least 2 Kowra. If a very strong load is assumed, there may be more.

- Treat surface with sandpaper. You can also shoot the edges for security (if in the house is children) or for beauty.

- Connect the upper and lower booms of the beam, drinking them to a quarter along both sides. Anchor bolts are best suitable as fasteners. Also, the boosters can be additionally attached to the walls.

- When using one tutor, you need to shorten it to the required length. Drink openings inside it for steps. Secure the tutor on the wall anchor bolts. To regulate the exact position of the guards and cosomes, use the construction level.

Installation of steps and risers

- Split the beam based on the calculations - the number and width of the risers. Rob them with each other and treat sandpaper.

- Secure the risers on the platter from the front side with the help of self-tapping. Do not worry that the type of self-sores will break the aesthetics - they can later be sharpened or hide under special decorative "closers".

- Split the wooden beam based on the calculations for the steps. Remember that the last step is the floor of the second floor, therefore, from the total number we take 1 pcs.

- Treat the surface of the sandpaper and ellipped the angle protruding the outer edge.

- Put the steps on the risers and secure them with screws or screws.

- Install the balusters and secure them with pillas 100 * 8 mm.

- Set the railing on balasins and secure them with self-draws.

Wooden staircase on the second floor is ready! It remains only to cover it with varnish and add decorative elements if necessary.