Heat insulation materials for walls Insulation,Building materials

A truly cozy and comfortable can only be called the house in which it is always warm. In order for him to really be necessary to choose a high-quality and reliable thermal insulation material for the insulation of its walls.

Content

What properties should the thermal insulation material for the walls?

When choosing a suitable heat-insulating material for insulation of the house, it is necessary, first of all, to pay attention to its main characteristics:

- Fire safety. The insulation must meet all current fire safety standards, namely, reliably resist high temperatures and not to maintain the burning process in order not to contribute to the spread of fire.

- Low thermal conductivity or heat transfer rate material. The lower the thermal conductivity, the thinner can be the insulation and less area it takes indoors;

- Lack of shrinkage, as it can cause loss of insulation of its thermal insulation properties;

- Ecology. Any insulation that is used for the thermal insulation of the room should not be toxic and allocate any substances for the human body.

- Water resistance and vapor permeability. The ability of the material does not absorb moisture and effectively remove pairs from the room - these are the main indicators to pay attention to.

- Durability. The service life of such a material should not be a smaller service life of the building, for the insulation of which it is applied.

Types of thermal insulation materials

Today consumers have a huge selection of a wide variety of means for thermal insulation of houses. Consider the most popular of them separately.

Fiberglass

It is a thermal insulating material that is obtained from molten glass and is used most often for the outer insulation of the walls.

- Fiberglass has excellent heat and sound insulation characteristics, it is not afraid of fire and is not amenable to rotting processes, does not highlight harmful toxic substances and absolutely safe to the health of those surrounding people.

- The only drawback is its fear of mechanical loads and sensitivity to water. When water enters the fiberglass, the thermal insulation properties of this material deteriorate significantly.

Mineral wool

Thermal insulation material of natural origin, which is made on the basis of basalt fiber.

- Mineral wool has excellent heat and sound insulation properties, depending on the weight and its structure, it is also highlighted with vapor permeability, compressive strength, bending and gap.

- This material is environmentally friendly and safe to people's health.

- A significant drawback of mineral wool is its hygroscopicity or sensitivity to water. To get rid of this, many producers impregnate it with special hydrophobic modifiers to give such insulation water-repellent properties.

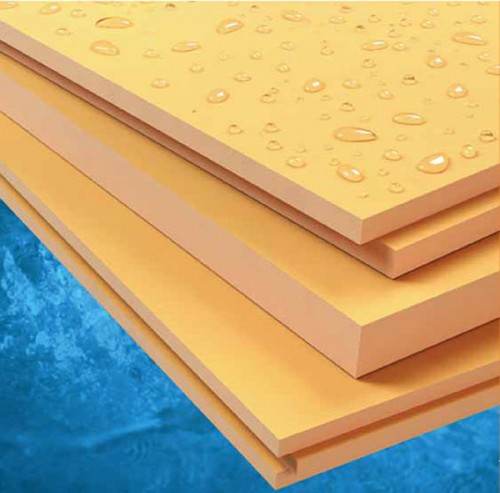

Extruded Polystripol (EPPS)

The material that represented the set of small, in any other non-related cells, which are filled with gas and do not let the water and pairs.

- The cellular structure allowed Epps to gain such qualities as low thermal conductivity and water absorption, high strength and resistance to temperature differences.

- The extruded polystyrene foam is produced in the form of plates that can be easily cut, it is not afraid of fungus and mold. Such qualities allowed to use this material, first of all, for the external thermal insulation of the walls of basements and the foundation.

- The only drawback of EPPS is his fire hazard.

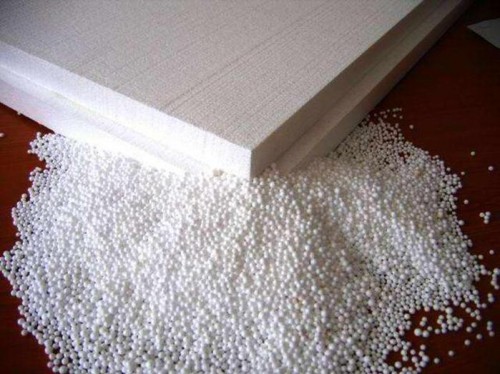

Polystyrene foam (foam)

This material is also called foamed polystyrene foam.

- It is distinguished by hygroscopicity, low thermal conductivity and affordable cost.

- However, such a deficiency, as low vapor permeability, significantly limit the scope of its application. It cannot be used for the outer insulation of wooden structures with high humidity inside, for example, for baths, saunas, etc.

- In addition, the foam, like the previous material, is easily flammorated and maintains the combustion process, while it is distinguished by a very dangerous toxic gas for human health. It is more suitable for the insulation of the facades of brick buildings, followed by their plastering, which will make it possible to save on heating.

Polyurene Foolder

Presents the polymer material obtained by foaming.

- It has waterproof, is not afraid of the harmful effects of microorganisms and fungus.

- This type of thermal insulation material is produced in the form of plates, panels, blocks and sandwich panels. They are used for outdoor and internal insulation of various buildings and structures.

- Polyurethane foam in the form of a mounting foam, which is applied by spraying, is used to finish facades.

Basic manufacturers of thermal insulation materials

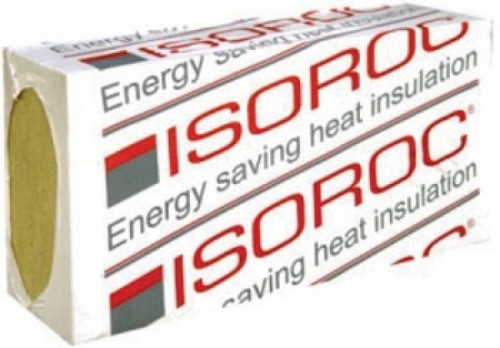

Isoroc (grinding)

Under this brand, thermal insulation materials based on basalt rocks are produced. The company offers its consumers a wide selection of insulation of various thicknesses, forms depending on the climatic conditions and the type of building structures for which they will be applied.

- The insulation of Isoroc (grinding) can take the shape of plates, mats, rolled cloth, cylinders and half-cylinders.

- This product is characterized by high resistance to deformations for compression, durability, refractory, low thermal conductivity.

Rockwool (Rockwill)

The thermal insulation products of this brand are produced based on stone wool basalt breeds. It is applied not only as a heater for external or inland walls, but also for sound and fire protection of various structures, pipelines, etc.

- Like the thermal insulation materials of other manufacturers, the mineral wool of basalt rocks is distinguished by moisture resistance and vapor permeability, strength and resistance to corrosion, with an affordable price.

- Rockwool (Rockwill) is also used to arrange ventilated facades of buildings.

More detailed process of outdoor insulation of walls with the help of the thermal insulation of Rockvul can be seen on the video:

More detailed process of outdoor insulation of walls with the help of the thermal insulation of Rockvul can be seen on the video:

Izovol (Isowing)

The thermal insulation material of the new generation, which is made on the basis of stone wool.

- It stands out with all the necessary quality for insulation and is used for the external and internal thermal insulation of walls of private houses, apartments, industrial enterprises, etc.

- Products of this brand are produced in the form of plates, sandwich panels, cylinders and others.

In addition, thermal insulation for the walls of the Knauf trademark (KNAUF), Pleeplex and others is not less popular.