Metal-profile fence with their own hands Construction

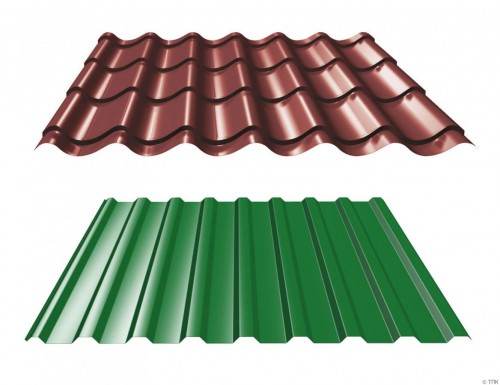

Still fresh in memory of memories when the profiled construction sheets were a depressing spectacle. Produced from galvanized material, sheets found an application for decoration of the roof in a warehouse, a garage or other inconspicuous construction. A simple rigorous material was reborn and became one of the most sought-after market.

Content

Fresh view of metal

Manufacturers, thanks to perennial efforts, the profiled flooring was removed for a high quality and aesthetic level. Developers tried to combine quality and external appeal. As a result, modern professional flooring is a revolutionary material, based on the same uncomplicated durable galvanized sheet. However, the appearance of the material became an order of magnitude elegant. For example, the outer side is now offered with a polymer spraying.

As a result, manufacturers have achieved two important criteria:

- an increase in the protective properties of the coating;

- decoration of an inconspicuous galvanized sheet.

Today it does not surprise that many developers began to pay attention to this material when creating roofing, fences and even retractable automatic gates. And as practice has demonstrated, the fences from the professional flooring have won popularity among the people. The cause of everything was a children's simplicity of installation of the material. Even newcomer can cope with the fence device from the metal profile.

Advantages of professional flooring:

- versatility (material is suitable for roofing, wall sheat, fences facilities);

- strength (material withstands hail blows, human weight and ice weight);

- glossy surface;

- reliable waterproofing;

- corrosion protection;

- wide color decoration palette;

- combination with other finishing materials;

- long service life (up to 50 years);

- easy installation (you can make a fence from metal profile in a couple of days).

Finally, the latest factor in popularity is the availability of professional flooring. The financial side of the issue plays an important role in construction. From this not to leave. But any construction requires careful calculation and preparation. Only after the calculation and the preparatory stage is fulfilled, it is recommended to start directly to construction, whether it is to collect the household building or installing a fence from metal products.

How to choose a professional flooring?

1. Purpose of application.

When choosing, keep the marking of the material:

- N - flooring (roof);

- Ns - universal coating;

- C - wall (fences, walls, facades).

Each type has its own distinctive features. So, for example, H has a corrugation height of more than 20 mm to increase strength. It is needed for maintaining snow and human weight.

2. Sheet thickness.

The thickness of the material, the more durable. For a temporary building, C-8 thick up to 0.8 mm is consistent.

3. Weight of professional flooring.

The mass varies within 4 - 24 kg per 1 m².

4. Height of the corrugation.

The higher the corrugation, the harder coverage. As a result, stronger and more reliable. The best support characteristics belong to the MARKAM N-60, N-114. The thickness of the material in this case is almost 1 cm, the mass is up to 12 kg.

5. Type of coating.

From the choice of type of coating sometimes depends the strength of the structure. Sevecent seven main types:

- polyester (budget option with a rich choice of palette);

- aluzink (protects coating from scratches and darkening);

- zinc (most economical and short-lived option);

- a mixture of polyester and teflon (wear-resistant material);

- PVDF (polyvinyl difluoride-acrylic) - ensures effective protection against ultraviolet and chemical impact;

- polar (resistant to fading and mechanical damage material);

- plaserisol (a mixture of PVC and plasticizers is the most resistant to external feature material simulating various types of coatings).

The selection variety expands your capabilities. With a small budget of the project, you can buy galvanized sheet metal sheets for the fence. If the possibilities are not limited to financial vise, you can refer to the plastisol or a pural. These are the most aesthetic and high-quality materials.

The main thing is to determine the goal. For how long is it necessary for any design? What is the price of metal profile for fence? What are the size of the site and the desired height? Based on this, the calculation and subsequent installation is made.

Calculation of necessary materials

To assemble the fence from metal profile, you need to have the following tools:

1. Cement and gravel.

2. Coloring means for applying to lags and pillars.

3. Self-tapping screws.

4. Cross lags. Metal pipes are also used with a cross section of 60x25 mm. It is important to remember that the thickness of the pipe wall should not be more than 2 mm.

5. Racks. Various options will be suitable as supports for the fence:

- stone or brick poles;

- metal profiles;

- pipes;

- logs.

The most fiscal option will be pipes. The cost of material is low, installation is simple and fast. It is advisable to choose pipes with a diameter of 59 mm.

6. Actually profiled sheets themselves. The material is made to install roofing and fences, but both categories are interchangeed. For a fence from metal products, as in video, it is advisable to choose the material of the crest to 21 mm.

Finding out what materials are needed, the amount should be determined. To spend competent calculation, refer to the design project of your metal harness. Determine the height taking into account the length of the sheet. By the way, in standard form it reaches 12 m. Owing to this figure, it is recommended to cut the material on a multiple number of parts to avoid waste. It must have pieces 4, 3, 2 m.

As an example, choose a 2-meter fence. Then the length of the fencing site is calculated. The values \u200b\u200bof the width and length are known, now it is necessary to proceed to the final computing. But before this, it is desirable to deduct from the "square" space under the gate and the gate, if any conditions are provided for by the terms of the design project.

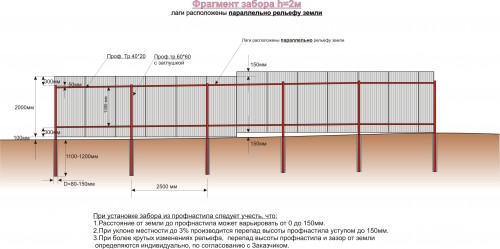

After you count the number of racks and size. With the height of the fence in 2 m, the pillars must be at least 2.7 m. The fact is that setting supports in the ground is recommended according to the construction technology, that is, by 30% of its length.

The total number of racks is calculated after determining the length of the fence. In perfect design, pipes as a support should be located 2.5 m away from each other. This is the most optimal option for installing pillars for a collection of metal products.

As for the transverse lag, their number is found on the basis of the regimen and perimeter scheme. Remember one nuance: at the height of the fence, 2 m is required to assemble the design in three rows. The total number of self-samples is not difficult to determine. One sheet will need 6 or 9 pieces depending on the two or three-row lag.

Package assembly stages from corrugated

1. Conducting earthworks. If you have decided on the number of necessary materials and the distance for installation of racks, proceed to the preparatory work. If the racks are already installed, the first pit need to dig around the extreme support. Armed with a shovel, you should dig a hole with a depth of about 1 m. To facilitate the process, you can use the Garden Brown. After the first pit, it is started to the second and subsequent with a step of 2.5 m. Be sure to take into account the space for the cushion from the gravel.

2. Foundation device. It is not desirable to bring the concrete mixer and prepare a large amount of solution. It is advisable to limit ourselves to small kneading for concreting one or two holes. The proportions for the preparation of the solution are as follows:

- cement brand M400 - 1;

- gravel - 4;

- water.

3. Installation of racks in pitting with subsequent concreting. Installing supports required vertically. Concrete is mandatory connected by primary means. This is a mandatory procedure, as a result of which the air is released from concrete.

4. Staining pipes with soil water repellent.

5. Installation of transverse lag. The installation stage of the lag must begin after drying the concrete foundation. There are two ways to attach lag to supports.

The first provides for the use of electric welding. This simplest method, unfortunately, is not available for the average man. But if you have experience with welding equipment, cards in hand. Otherwise, you will have to call a specialist. Then the process of independent creation of fence loses relevance.

Therefore, we offer the second method. Racks and lags are connected using bolts. For this you need:

- drill through holes in the rack and lag;

- secure pipes with a bolted connection.

It should be remembered that the installation of transverse lag is carried out at a distance of more than 20 cm from the base and edge of the pillar.

6. Lag staining with soil water repellent composition.

7. Installation of professional flooring. This is the most exciting and simple stage of assembling of the fence from metal products. Each sheet, as shown in the photo, is strictly vertically exhibited using a laser level. Fix the sheets with self-assembly using a screwdriver. Two fasteners around the edges, the main accurate in the middle of the lag. Moreover, each next sheet material is mounted with a mustache.

Continuing to install sheets, the entire frame area is covered. This can complete the construction. But we passed several unique tips for you.

Nuances of the construction of a fence from a professional flooring

- Creating a fencing from metal profile must comply with the requirements of the house design and the site as a whole. Harmony, complete correspondence of the gate and fence, economic buildings and housing is important. Everything should combine the overall design concept. Therefore, if you wish, you can shelter the gates and a housekeeping or chosen or pick up the color of metal products for the fence in the tone.

- Under the material you can remove the top layer of the soil and make concreting base. A peculiar scene from the outside and inside will complement the composition and will protect against the penetration of cats and other unwanted visitors.

- The open edges of the support racks are desirable to close. In our case, it can be decorative balls, tips, peaks and other elements. The choice of decorative parts is huge.

- The device of the fence is associated with all its components should fit not only in the overall concept of style, but also to meet safety requirements. Do not save on building materials. For example, such a simple trifle as a self-tapping screw, without water-repellent spraying, can lead to the destruction or deformation of the fence.

Conclusion

You can make a simple conclusion that you can collect a fence from metal products in your own hands, subject to the mandatory compliance with the installation technology. You could make sure nothing is difficult in this. The only one, it is necessary not to regret on the materials and responsibly approaches each stage of collection of construction. For disregard in construction punishes sad consequences. In our case, it is a skew of the fence, deformation of the supports, a decrease in stability and reliability.