How to make a roof on the balcony Useful advice

Apartment owners perfectly understand that the presence of a balcony is slightly expanding the total housing area. But to make it absolutely useful, it is necessary to install a reliable roof. On how to make a roof on the balcony, we will talk now.

Content

Types of roofs

Depending on the design features, balcony roofs are divided into:

- autonomous;

- dependent.

Autonomous roof

This design is attached directly to the building wall. This technology is simpler. Yes, and the price of such a roof on the balcony will be lower than the dependent design. In essence, autonomous roofs are bearing frame structures that are made of metal corners. Corners act as the basis for the crate and roofing.

When installing an autonomous roof on the balcony there are various options for the improvement of this part of the apartment. There are no restrictions on the choice of type and size of the design and glazing systems. It all depends on the preferences of the property owner.

The disadvantages of autonomous structures include:

- the impossibility of the insulation of the roof on the balcony, since it is not related to glazing elements;

- weighing design with a wide balcony;

- the use of only materials with a small weight;

- easy coating may not cope with the loads of the blowing winds and dropping snow.

Dependent roof

This design solution involves the installation of supporting elements, the main of which are several aluminum or wooden frames. Due to the presence of all items, the installation of the roof of the balcony will not cause special difficulties.

Despite the fact that the device of such a roof of the balcony requires tremendous physical effort and financial expenses, this option is more reliable. The dependent design is characterized by sustainability to huge loads. For this reason, it is possible to cover the design by any roofing material.

A huge "plus" dependent roof - the presence of vertical racks. They serve as a reliable basis for frame elements with the glazing of the entire balcony. Also, the dependent design can be insulated and soundproofed.

Materials for the roof

The most common materials for creating a roof on the balcony are:

- soft roofing (flexible tile, ondulin, polymer membrane, other rolled materials);

- material made of steel sheets (professional flooring, galvanized, corrugated line);

- cellular polycarbonate sheets;

- roofing glass.

Soft roof

Amongulin uses the greatest demand among soft materials. Naturally, at a price to make the roof on the balcony from Ondulin is much more expensive than to cover it with metal roofing material.

But this technology has a fairly significant advantage: the roof will be with great sound insulation properties. The only requirement when using soft roofing materials is the device with the maximum hard crate.

Metal roofing

Many are wondering: And how much is the roof on the balcony made of metal, and what material to choose? Among such coatings, professional flooring is the most popular. This material has the most optimal indicator of the price and quality ratio.

Tabletail can be covered both dependent and independent structures. It has excellent structural stiffness. Due to this, the material without deformation changes withstands the load of wind and snow. The only drawback is the low sound insulation of the metal roof.

Cellular polycarbonate and double glazed windows

A clear roof made of polycarbonate looks very effectively. This design is resistant to mechanical loads and the negative effect of ultraviolet rays. Polycarbonate is distinguished by a solid operating period, during which the structure of the material is not destroyed.

A more expensive option is a glass-colored roofing material. For its production, a special tempered glass is applied.

Installation technology

It should be noted that roofs of houses with a balcony (in the photo) must have maximum simplicity and practicality. The angle of inclination is in the range of 15-75º. If there is a minimum inclination angle, it is possible to save roofing material.

If the roof is created, the slope of which is 75º, then you can confident that the falling snow will not stay on it for a long time. Naturally, with the arrangement of the roof of the roof of the balcony about saving materials, it practically does not go. The second option is more suitable. Typically, the tilt of the design is made in the range of 45-60º.

At the initial stage there is a framework of a frame, which can be:

- metallic;

- wooden.

Metal design is distinguished by a large service life. It is absolutely fireproof and with the lattice better protects from unwanted visitors. Among the disadvantages of the metal frame, it should be noted the high cost of materials and attracting specialists for welding.

Wooden doom - more acceptable option. It is easier to work with this material, and the new roof of the balcony will cost much cheaper.

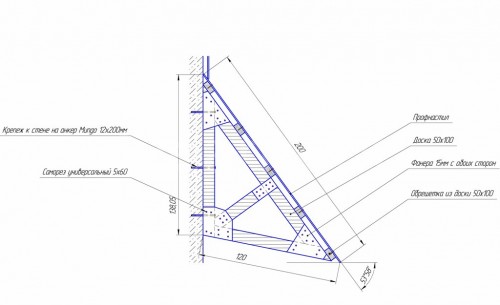

Build a wooden crate

The width and length of the frame is influenced by the size of the balcony itself. As for height, it should not be very big. With a strong rain, which is accompanied by the wind, the balcony will be poured with water.

To determine the optimal height, the growth of the highest person in the family is taken and 20-25 cm is added to it. On average, the height of the design is about 2 m. That is, the upper part of the supporting front beam, which will be covered with roofing material, should be located at a two-meter height. As reference beams, you can use a timing segment 7 * 5 cm.

Creating a framework provides for the implementation of such works:

- Thin bars (3 * 3 cm) are attached to the wall around the perimeter of the balcony door.

- Side bars should be on the same level with a transverse timber.

- The reference timber is placed in the corners of the balcony construction in a strictly vertical position.

- Using metal corners, the support elements are attached to the railing linings.

- In the presence of highly discovering linings, the grooves under support is recommended to cut down to the base.

- Mounting the horizontal support beam.

- It uses a metal corner for its reliable fixation.

- The fastening of two beams, which are located between the bars, brushed to the wall, and the horizontal support beam.

- Laying inclined beams. They must lie on the bar above the door and on the support beam.

- For a more dense stop of oblique beams in the support structure, you need to cut the small grooves.

- After laying all inclined beams, they should be securely fastened.

Installation of roofing

Before finally install the roof on the balcony, all wooden bars are processed by an antiseptic. Immediately harvesting roofing material. Cutting professional flooring or polycarbonate can be carried out using hacksaw. But it is better to use the grinder (professional flooring) and an electric bison (polycarbonate).

Laying professional flooring

Fastening the roofing material to the crate is made by self-drawing, which are complemented by sealing washers. The sheets of professional flooring are stacked by the Vangest, the value of which is determined, based on the size of the billets. The standard number of self-samples is 8-12 pcs. / 1 \u200b\u200bm².

After installing the professional flooring, all the gaps between the material and the wall are closed. To do this, use a mounting foam, which fill in the inner slits. Concrete solution and silicone sealant are used to eliminate the outer cracks. If in the future the glazing of the balcony will be performed, then the extreme part of the roof will be strengthened with an additional bar.

Polycarbonate fastening

For the roof device, a cellular polycarbonate is used with a width of 0.7 or 1.05 m. For fastening the roofing material, tapes with thermoshabami are used. Thermoshaba is an element that consists of three parts:

- latching cover;

- sealing washer;

- plastic washer with leg.

Such mounting elements are purchased, which in size will correspond to the thickness of the polycarbonate panels. The leg of the thermoshabes should be restricted into the crate. Only this will be prevented by crumpled panel. For this reason, the holes in the panels are made by 2-3 mm more than the diameter of the fastener.

When working with polycarbonate, the most close attention is paid to the sealing of the end parts of the panels. To seal upper ends, an aluminum self-adhesive tape is used, the lower ends - perforated tape.

Useful advice

High-quality roof installation on the balcony implies compliance with a number of requirements. The main ones are:

- When buying a wooden bar and beams, you should pay attention to the quality of the material. It should not be with bitch, chips or cracks.

- In addition to the antiseptics, wooden elements are recommended to cover with fire-resistant composition.

- If the tapping screws are hardly screwed into the hardwood, then you need to make a small hole with a selection, and rub the screws with soap.

- Selection of roofing material is based on the climatic conditions (precipitation, number of days with strong winds and so on.).

- In the process of installing roofing material, you need to constantly check the reliability of its fastening to the frame and walls.

- When laying insulation and protective elements, additional rails are used for their reliable fastening.

Video Device roof on the balcony: