Noise insulation doors with their own hands Doors,Plumbing

The high-quality entrance door, to the house or apartment, is obliged to protect it from the emergence of unwanted people. In addition, the door must be fencing the tenants from the various sounds of conversations and steps coming from the floor. In addition, each indoor person feels more comfortable when he knows that he can lead a conversation, absolutely not afraid that he can hear it. Therefore, the question is how to make noise insulation of the door - it remains relevant to many.

Content

Noise insulation doors

Of course, among the existing model line of products, modern entrance doors can be seen from well-known foreign manufacturers, characterized by quite high heat and sound insulation. However, such a high-quality entrance metal door with noise insulation has a somewhat overestimated cost. Advantageously, many consumers prefer domestic factory making doors, and even the products produced by a handicraft method at home. Such doors are a steel sheet with a welded corner. At best there is a few more rigidity.

But each harass choose the optimal design option. The question is how to turn the "object of increased noise" to the input doors with noise insulation has the following solutions:

- noise insulation doors with their own hands;

- installation of another, inner wooden door (arrangement of a peculiar tambour);

- combined method: noise insulation of the existing door and the arrangement of the Tambura.

It should be noted that the installation of an additional door will require significant additional resources, including financial and temporary costs. Yes, and if third-party noises behind the door decrease significantly, the noise from the metal door itself will remain almost at the same level. The best result is obtained by implementing a combined method. Moreover, in this case, the noise insulation of the apartment can be performed primarily, and then install the second door. And yet, it should be borne in mind that such noise insulation of doors, the price of which can exceed the cost of high-quality door, is not the most ideal option.

Proper noise insulation Doors: analyze options

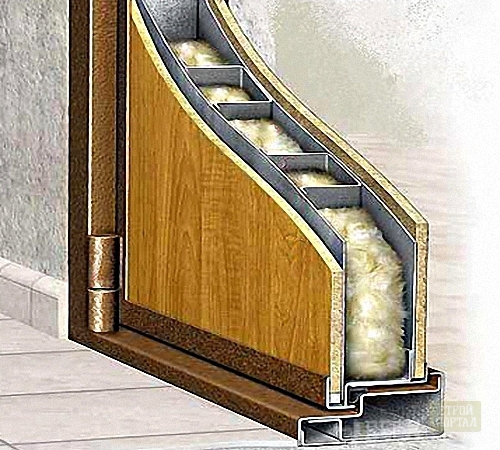

Depending on the design of the door, there are several options for performing noise insulation. If the door of the door is made of two metal sheets (outdoor and internal) and has an unintended design (the inner sheet is welded around the perimeter to the door frame), it is recommended to perform an exterior decoration on both sides using various sound-absorbing materials. The benefit of the modern market of building materials allows you to choose the optimal version of noise insulation, both at the price and operational parameters.

If the entrance door has a collapsible structure that allows you to remove the inner sheet of metal, or the door is a design of one steel sheet with a welded frame, then the noise insulation of the doors is carried out, as a rule, a way to fill the inner cavity with noise insulating materials. In addition, regardless of the design of the door leaf, throughout the perimeter, the gap between the web and the door frame is eliminated with the help of special seals. Also often installed additional door thresholds.

Materials for noise insulation doors

External entrance doors can be performed:

- from the array of wood,

- mDF plates,

- artificial leather, using sintepon, foam rubber, etc..

- The choice of finishing material depends, first of all, from financial capabilities. The only thing to pay attention to is to fasten the finishing materials to the metal door canvase. Agree, nails are not suitable for this.

A possible variant of the optimal noise insulation of the metal door is the use of a rolled heat insulator EnergoFlex or isolon on a self-adhesive basis. But in this case, it will take additional finishing of the upper surface of these materials to improve the decorative type of the door, for example, artificial leather. Today, this material is available in a wide textured and color scheme, which will allow it to choose it for any color solution of the interior. Experts recommend using the dragon adhesive for gluing the decorative layer.

The assortment of materials to fill the inner cavity of the door cannons is also quite wide. To implement this method, use:

- mineral wool (basalt fiber),

- styrofoam,

- foamed polyurethane.

Each of these materials has its advantages and minuses, so it is important to choose the "Golden Mode". For example, basalt fiber is, in contrast to foam, non-combustible material. But over time, this material is compacted, which leads to a sediment. You can eliminate this disadvantage using additional stiffeners.

Foam, on the contrary, well maintains a form, has a higher density and minor cost. However, its flammability and distinguished harmful substances significantly reduce consumer qualities. In any case, inside the premises it is used quite rarely. For a number of technical and performance characteristics, foamed polyurethane is probably the most suitable option for noise insulating material. As practice shows, metal doors with noise insulation of foamed polyurethane have a number of undoubted advantages.

How to make noise insulation doors

Like any other production process, the performance of noise insulation begins with the workpiece of materials and the preparation of the necessary tools. Before making noise insulation doors, you should prepare the following tools:

- electric drill;

- set of drills for metal;

- wood hacksaw;

- knife;

- scissors;

- hammer;

- screwdrivers (screwdriver with a set of bit);

- construction stapler;

- consumables (self-reading head screws, decorative nails, staples for stapler, glue, etc.).

Depending on the method of performing noise insulation, the tool kit can expand or shrink.

Before performing work, you must remove all the additional elements (door handles, eyes, etc.). When performing an external decoration of the door of an indiscriminate structure using an energy source or isolone on a self-adhesive basis, the material is glued to a preventive surface of the web. Then, with the help of the "Dragon" adhesive, a decorative coating is fixed (for example, artificial leather). Before applying glue, it is recommended to breed with technical alcohol. The glue is applied to the surface of an insulating material. After drying, mounted hinged elements and the door is ready.

Noise isolation of the door with collapsible design is characterized by both the selection of noise insulating material and the technological process. It is preliminarily to remove the inner sheet of metal, and then fill the cavity of the insulating material, fixing it with adhesive composition ("moment", PVA, "Liquid nails", etc.). If there are noticeable slots between the frame and the outer sheet, it is recommended to eliminate them, for example, using silicone sealant. The same procedure should be repeated after installing the inner sheet of the door web.

To perform noise insulation of the metal inlet door without an internal sheet, wooden rails will additionally need, as well as a sheet of plywood. The technological improvement technology is as follows. Their wooden rails are made of a frame that is inserted inside the metal frame of the door and is fixed with self-drawn through the holes previously drilled in the corner. Then the insulating material is stacked. From above, the inner cavity of the door leaf is sewn plywood. It remains only to fix the decorative coating, install door handles and eyes.