Waterproofing terraces with their own hands Insulation

Most country houses have terraces and balconies. This is the most comfortable and cozy place to relax in the fresh air. Because the terrace and the balcony are open-air, for their protection against adverse atmospheric factors, special waterproofing activities are required, which are easy to perform with their own hands.

Content

- How the terrace is arranged

- How to perform waterproofing terrace and balcony with your own hands

- What materials are used for waterproofing terraces and balconies

- Waterproofing with liquid materials

- Types of facing terrace or balcony

- How to restore the waterproofing of the terrace simplified

- Features of waterproofing level terrace

- Waterproofing of an open terrace and a balcony based on cement

- Waterproofing systems based on liquid bitumen

- Waterproofing systems for terraces and balconies from self-adhesive membranes

- Waterproofing systems from mineral materials for open terraces and balconies

- Waterproofing terraces and balconies with their own hands video

How the terrace is arranged

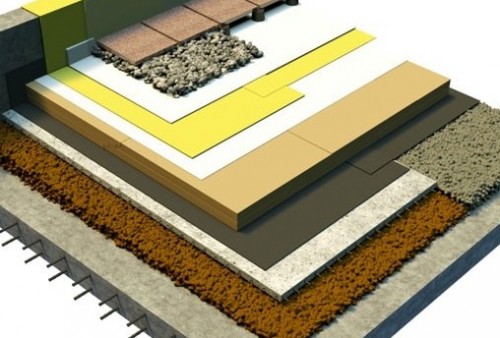

The terrace has a multi-layered structure, including the actual waterproofing coating. Each of the remaining layers also has in one degree or another with waterproof properties. And only in the complex, multilayer terraced pie ensures reliable protection of the construction structure from the destructive action of moisture.

The level terrace is usually located above a residential premises, therefore it requires an additional insulation with vapor barrier, in addition to waterproofing and drainage. Standard solution of the device of the outdoor multi-layer "Cake" of the terrace:

Floor slab

Plate of overlap is the lowest level. The terraced plate or floor overlooking the room is usually a reinforced concrete plate, molded horizontally or with a slope of 1-2% outward for the natural flow of water from the surface of the terrace. If the slab without a slope, it is formed by the flap (the fastening layer) is a cement screed.

The advantage of the inclined option in the absence of the need for a bias-forming layer of a cement screed, which is an additional load on the overlap.

Parosolation

On top of the slab of the overlapping or on the incinerate screed, the vapor insulation layer of the construction film or the rubberoid is laid, to protect the heat insulator from the penetration of water vapor from the dwelling. The vapor barrier film is removed on the wall at the level of the door threshold.

Heat insulation

The thermal insulation is performed from polystyrene foam or extruded polystyrene foam. The overall thickness of the insulation is 12-20 cm.

The thermal insulation layer prevents the heat leakage from the room located under the terrace and prevents the formation of a cold bridge through the joint of the terrace with the wall.

Waterproofing

The waterproofing film of poetic or polypropylene with a thickness of 0.2 mm protects the heat-insulating layer from the penetration of moisture outside and serves to separate the presser screed and insulation.

Clamping layer

The clamping layer is called a reinforced cement screed with a thickness of approximately 4-5 cm. Simultaneously performs the function of the lining layer under the coating. The reinforcement is made in the form of a mesh with cells with a size of 10 × 10 cm from steel rods with a diameter of 3 mm. In the clamping layer there are temperature seams. Distinguish featured and forced seams. Forced seams delimit the screed into squares with an area of \u200b\u200bapproximately 4 m². Forced seams have a width of 10-12 mm, and a hundred-hot-minimum 15 mm.

Solid waterproofing

It is performed on top of the presser layer and is a seamless waterproof membrane with a thickness of at least 2 mm. It is made of polyurethane or mineral masses. Waterproofing is used to protect the terraced slab from destruction. Bullystrade is better fixed in the ends along the lower edge of the plate so as not to damage the waterproofing.

Top finishing coating

As a facing coating, frost-resistant ceramic tiles, decoing, wooden flooring. The finishing material is placed on the waterproofing layer and protects it from mechanical damage. When cladding, the tile coating necessarily provide compensation seams in the form of longitudinal slots of about 10 mm wide. In temperature seams, a special elastic cord is layered from polyurethane or polyethylene. Alternative method of sealing seams: filling with acid silicone for external work and the formation in the seam profile in the form of a concave meniscus.

How to perform waterproofing terrace and balcony with your own hands

Installation of waterproofing coating Terrac and open balconies is an absolutely necessary stage of construction and repair work. It is important to choose high-quality materials with high waterproof and wear characteristics, to competently equip the entire waterproofing design to ensure reliable protection of the terrace and balcony from the devastating effect of weather-corrector.

The protruding parts of the building are subject to significant deformations, so the system of waterproofing should be resistant to the formation of cracks.

How to make a slope

What material did not have a terrace, compulsory requirement for its arrangement - adherence to the elongation to the outside for the natural removal of rain and melt water. Quite often, during the construction of balconies and level terraces, the developers admit miscalculations in the base structure.

The absence of a slope leads to stagnation of water, penetration into deeper layers, leaks appear in the future, the plates are freezing, which results in the destruction of concrete.

Blutter is most often formed on the surface of the concrete slab, which is the basis of a terraced construction. Another way: on top of the smooth plate is placed on an angle of 1.5-2%. Such an angle is sufficient for water convergence and at the same time eliminates the location of the overlying layers. In the outer edge of the terrace, the thickness of the evadroduction layer should be at least 3.5-4 cm, otherwise the floor will crack and crumble. So, with a bias of 2% on the terrace, three meters wide, the fastening layer at the outer edge has a thickness of 4 cm, and the wall is 10 cm.

The mass of the evasion-forming layer is quite significant, which should be taken into account in the design calculations.

Clamping layer order

The cement screed serves simultaneously with a pressed layer for insulation and a steady base for the upper flooring.

Usually the thickness of the screed is the same on the entire area of \u200b\u200bthe terrace and is 4-5 cm.

On large terraces it is recommended to pave a longitudinal and transverse reinforcement of a screed, which will not give her to cooke. For reinforcement, steel rods are used by cross section 3 mm or a grid with cells 10 × 10 cm or 15 × 15 cm.

What is compensation seams

In the clamping layer of balconies and terraces (tie), it is necessary to provide a compensatory seam (another name - temperature or dilatation). The compensation seam is a longitudinal slot of 10 mm wide, provides free deformation of the concrete coating, prevents the formation of cracks.

The seam is filled with a cord of polyethylene or polyurethane and an elastic mass, for example, silicone, giving it a form of meniscus.

Fixed seams located at the junction of walls and a terrace plate, and forced - separating the screed on the plots (paintings) of 4 m².

The width of the width of the compensation seams should be at least 1.5 cm, and forced - 1-1.2 cm. The depth of the seams exceeds the width of several millimeters.

On the terraces, compensation seams have a form of a mesh of squares with a size of 2 × 2 m, on long narrow balconies with a width of approximately 1.5 m of the seams are located with an interval of 3 m along the lines of the slope.

If the clamping layer without reinforcement, then the compensation seam is carried out by the end of its thickness of the freshly abandoned screed by approximately 1/3 of its thickness, but not more than 2/3, observing caution so as not to cut the film under it.

If reinforcement of the zooming layer is assumed, the reinforcement is placed within the boundaries of fields (paintings), and in the places of future compensatory seams, metal corners are placed. After 14 days, after the screed grabbing, the corners are removed, and the gaps are filled with an elastic material.

Typically, a special elastic synthetic cord is placed in a slope slightly thicker. For example, a 10 mm wide slot is layered with a cord with a diameter of 12 mm. The cord comes into contact only with the edges of the slit, but not with its bottom, so that the voltage in the process of shrinkage of the clamping layer is not transmitted to the underlying layers.

From above, the cord is covered with an elastic mass, giving it the form of a concave meniscus, which will ensure the tightness of the compensation seam and will increase resistance to temperature differences. There are technologies at which they first lay the elastic mass to the bottom of the seam, and then the cord is placed in it.

Liquid waterproofing materials differ from each other according to the degree of elasticity, and to ensure reliable tightness, compensation seams are closed by sealing tapes. New waterproofing materials appeared on sale, which, thanks to high elasticity, make it possible to completely abandon compensation seams. This allows the waterproofing and adhesive layer of a terraced coating from the same material - waterproof polyurethane glue.

What materials are used for waterproofing terraces and balconies

The presence of slope is mandatory, but not the only condition to ensure the integrity of the structure. It is equally important to perform waterproofing. The modern building market offers at an affordable price a wide range of efficient materials for the waterproofing of a balcony or terrace: all kinds of mastic and rolled materials (membranes and films).

Materials from leading manufacturers for waterproofing terraces:

- Parosolation. Foil materials "Derken" or "PDT" (Germany).

- Row (organization of slopes to trap and trades). The cement-polymer compositions "Ardex" (Germany - Austria).

- Heat insulation. Polyurethane insulation "Puren" (Germany).

- Waterproofing layer. Liquid waterproofing "Enke" (Germany). Roll polymer-bitumen waterproofing "Bauder" (Germany). Rolled composite rubber waterproofing "PDT" (Germany).

- Drainage system (fast water removal from the base of the terrace or balcony). Drainage mats "Gutjahr" (Germany). Draps and trays - "Sita" (Germany).

- Facing coating (tile, bulk polymer floor, terrace). Special systems "green" roofs.

Liquid waterproofing materials form a seamless coating on the surface of the base. Rolled materials are membranes or films. With any method of waterproofing, it is important to adhere to the manufacturer's recommendations, comply with the sequence of work and compliance with technological breaks, as well as take into account restrictions in adverse meteo conditions.

Waterproofing with liquid materials

Before applying liquid waterproofing material, the concrete base should be carefully primed to reduce hygroscopicity. Usually use mineral primers that can penetrate into the base at a depth of 2 mm. A more efficient result is achieved at twofold processing.

The most vulnerable places of the terrace are the corners, compensation seams and adjoining the wall. They primarily need enhanced waterproofing.

In these problem areas, sealing tapes are paved, which are resistant to cracking due to elasticity and stability in a wide temperature range from -40c to + 90c.

For waterproofing work on the terrace, polyurethane mastic or mineral compositions (single or two-component), which differ in high elasticity are recommended. Apply a mastic in two layers at a time interval of 4-8 hours.

It should be captured by the coating waterproofing tapes on a width of at least 2 cm. Before starting waterproofing work with liquid materials, it is necessary to get acquainted with the manufacturer's recommendations for their use. Some mastic are applied only on a dry base, others - on a wet surface.

Waterproofing work is performed at a temperature range from -5 ° C to + 25 ° C, it is desirable for cloudy weather, because the material is heated in the sun and can flow. After applying the waterproofing layer, you should cover the treated surface from direct sunlight, at least 12 hours.

Types of facing terrace or balcony

Frost-resistant ceramic tile and porcelain stoneware are perfectly suitable for finishing the level terrace and balcony. The tile reliably protects the waterproofing coating from mechanical damage, durable and easily clean. The tile is placed on the elastic adhesive solution 24 hours after applying the last waterproofing layer. Interputer seams close up with a frost-resistant elastic fugue.

In the finishing coating, you should also withstand compensation seams of the clamping layer. They, as a rule, have a smaller width, but pass strictly along the axis of the main seam.

It is strictly forbidden to make temperature seams between tiles with adhesive solution or fugue. It must be done only with silicone sealant for outdoor work. In the same way, the seams are close in places of adjustment to the wall.

It should be noted that the floor covering of open terraces and balconies is strongly heated in the sun, so to reduce heating temperature, it is better to use light-colored tiles. Dark tiles are less resistant to temperature drops and is more often dugs.

The finishing trim of the terrace of a polymer composite has significant advantages: DPK does not rot, does not fade into the sun, it is easy to clean, environmental and durable.

The deck board (Decking) is installed on the lags system. Lags are fixed on adjustable leveling supports or directly on waterproofing. Decing is also used to cover parapet and disguise waterproofing on the walls.

How to restore the waterproofing of the terrace simplified

If the tile fell off on the terrace, the fetches were fed, leaks on the lower floor appeared - urgent repairs are required. There is a lightweight method of laying a new waterproofing of the terrace without dismantling the old tile. In this case, the problem is successfully solved using the effective waterproofing material of the resistrict. In addition, you will need to install new ties and a deck device from the DPK.

Rezitrix Classic is used for waterproofing terraces, balconies, various types of roof: exploited, inversion, ballast and landscaped. Resitrix Classic is characterized by exceptional persistence of punctures and deformations, the effects of ultraviolet, temperature fluctuations, is not subject to rotting and has a rootist. It is chemically neutral, does not smell and does not have a negative environmental impact. Put the material with a glue way. Respitrix Classic with a thickness of 3.1 mm is glued with the G-2000 glue over the existing tile.

The junction of waterproofing with a wall, parapet, columns and fence columns depends on the specific situation. Membrane Resistrix allows you to create reliable and durable waterproofing of the terrace or balcony of almost any geometric shape.

Features of waterproofing level terrace

The level terrace is called a wide balcony located on the second floor over any room or based on the support on the poles. If there is a residential premises under the terrace, then the overlap, which simultaneously serves as the base of the terrace, is required to inspire. In this case, the insulation layer is combined with the deviationing with the help of special wedges of polystyrene foam.

If there is already a minimum bias on the slab onto the slab, or a bias-forming screed is performed, the plates of conventional or extruded polystyrene foam or foam glass are used for thermal insulation. Polystyrene foam and foam glass are most preferable due to practically zero water absorption. For the insulation of the floor terrace floor, the PSB-C-35 brand is suitable and higher.

Waterproofing of an open terrace and a balcony based on cement

The traditional method of waterproofing device is laying of bitumen mastic between the bearing base of the terrace and the tie. New building technologies suggest the presence of a layer of waterproofing on the screed directly under the tiled coating, which allows to protect the base and the screed from the penetration of water and the effects of seasonal temperature differences.

Waterproofing directly under the tiled coating is performed by cement elastic compositions, which are single-component or two-component.

Elastic waterproofing is a fiber-marked composition on a cement basis, after which is mixed with a plastic fluid mass with high adhesive properties.

The waterproofing composition is applied to horizontal and vertical surfaces. The layer thickness ranges from 2 mm to 4 mm.

After complete drying and polymerization of the composition, a coating is formed, which distinguishes the following properties:

- high elasticity;

- waterproof;

- high adhesion, more than 2 N / mm², for reinforced concrete bases with cement screeds, as well as smooth, dense, surfaces from porcelain stoneware, ceramic tiles and natural stone;

- the ability to eliminate cracks up to 1 mm wide;

- resistance to carbon dioxide, sulfates and chlorides.

For the preparation of one-component waterproofing composition, the required amount of water is poured into a clean container. Then it is gradually falling asleep with a dry component and stirred with a construction mixer or an electric drill with a special nozzle on low revs before receiving a homogeneous consistency. Give a solution to strengthen for 5-10 minutes to completely dissolve chemical components. After re-stirring, the waterproofing solution is ready for use.

Two-component waterproofing consists of separate packages with a dry mixture and liquid.

First, the solvent is poured into clean container, then a dry mixture is poured, the proportions of the composition are already observed during packaging. The composition is thoroughly mixed by a construction mixer, it is allowed to brew a few minutes, mix again and proceed to operation.

The procedure for applying waterproofing composition

Moisturize the cement base with clean water from the sprayer so that the surface is wet, but without water clusters. The processed surface should not be glittered, but be matte.

To seal horizontal and vertical angles, protrusions and joints "Wall-Wall" and "wall-floor" use a special waterproofing tape, which is glued to a thin layer of the main waterproofing used, the rubber layer outward.

To enhance the waterproofing of the connecting and structural seams, the screeds are glued along the entire length of the junction of the tape. If the width of the seams exceeds 10 mm, then the middle part of the waterproofing tape is laid in the seam of the loop, and the edges of the tape are glued to the edges of the seam.

After gluing, the ribbon edges are coated with a second layer of waterproofing composition.

Inside the joint lay the cord of polyethylene foam diameter a little more width of the seam.

After waterproofing, the angles and joints are treated with the waterproofing composition of the entire surface of the screed. It is applied to the moistened surface with a smooth spatula in several layers.

To monitor the integrity of the waterproofing layer and in order to avoid skips, some manufacturers recommend using a fiberglass alkaline grid with 4x4 mm cells. The mesh is interpreted using a smooth steel spatula into a freshly mounted first layer of waterproofing solution. In places, the compound of the mesh web is performed by a latter, 10 cm wide.

Each subsequent layer of waterproofing composition is applied after the final drying of the previous one.

The second layer of waterproofing is completely closed with a grid. The surface is thoroughly aligned.

The composition is necessarily applied in several layers so as to obtain a waterproofing coating of the required thickness.

The total thickness of the waterproofing layer should be at least 2 mm, and on terraces over residential premises - at least 4 mm.

(Waterproofing foundation and terraces)

With hot weather, waterproofing mixtures dry too quickly and become viscous, in connection with which the difficulties arise when applied. Therefore, it is recommended to carry out work at the cool time of the day and storing the materials used in a place protected from direct sunlight.

After applying, the waterproofing layer needs to protect against a strong temperature difference, as well as atmospheric precipitation during the day.

At the end of work on the device for waterproofing the terraces, a technological break is required from 3 to 5 days for the "maturation" of the waterproofing layer.

After the time of "ripening" of waterproofing, it is proceeded to perform cladding. For decorations use ceramic tiles, clinker, natural stone, Decking.

Waterproofing systems based on liquid bitumen

When working with systems from the coating bituminous waterproofing, the surface is pre-cleaned and the Polysil TC 500 is primed up. In the adjoints, a quilt is installed from the repair mortar of the Repair Mortar Plus for the voltage distribution.

The total waterproofing of the entire terrace or balcony area is performed by liquid polymer film Köster Kbe Liquid Film in two layers. An alternative is an elastic two-component bituminous thick bead coating KÖSTER DEUXAN 2C (4-6 mm). In the joints of the walls and overlaps, as well as on the sections of the likely crack formation, the Köster Glas Fiber Mesh fiber mesh is placed on the first fresh waterproofing layer.

On top of the waterproofing laid the screed for protection against mechanical damage. Under the tie linked polyethylene film in 2 layers.

Waterproofing systems for terraces and balconies from self-adhesive membranes

Self-adhesive KSK membranes, cold applications are one of the simplest and rapid ways of waterproofing balconies and terraces.

At first, a liquid polymer film Köster Kve Liquid Film is applied to a pre-cleaned concrete surface as a primer, which serves as a clutch of the waterproofing layer with concrete. At temperatures below 0 ° C, the KÖSTER KSK Sp is used.

In the joints of the walls and overlaps instead of carton, the triangular cord-sealant Köster Ksk Triangular Ribbon is used. Remove the protective film, apply the cord to the prubounding corner and tightly pressed. Roger can be made from the repair solution Köster Repair Mortar Plus and establish before applying the soil.

For the waterproofing of the total area, KSK SY 15 membranes are used. At temperatures below 0 ° C, the self-adhesive membrane KOSTER KSK AW 15 is recommended. The waterproofing membrane is glued to the prepared surface with the allen 10 cm on each side.

If the waterproofing membrane is glued to the wall, then it must be fixed by mechanical manner, and the connections and science to scapinate bituminous paste Köster BS 1 Bitumen Paste. If the upper edge of the waterproofing has to be placed, then this place is pre-protected by self-adhesive ribbon Köster Butyl Fix-Tape Fleec.

On top of the waterproofing, the polyethylene film in 2 layers is filling. And then put the screed. Screed protects waterproofing from mechanical damage.

Waterproofing systems from mineral materials for open terraces and balconies

For waterproofing balconies and terraces, mineral-based materials are made, for example, the coating of NB Elastic Gray (white or gray). This type of waterproofing is resistant to aggressive environmental factors, it can be applied to the wet surfaces and cover with tiles.

Before applying waterproofing, the surface is processed by primer KÖSTER POLYSIL TG 500. In places of connection, the floor / wall is installed from the Köster Repair Mortar Plus repair solution. For additional strengthening of the adjoins and prophylaxis of the coating in the first freshlylandic waterproofing layer, the Köster Glas Fiber Mesh fiber is pressed.

To restore concrete, a multifunctional repair solution KÖSTER BETOMOR MULTI A. The concrete surface is mechanically cleaned. From the reinforcement, it is thoroughly removed rust with sandblasting. With serious damage, reinforcement reinforce.

Minor damage to the concrete surface is enough to align the Köster C-Coat coating and paint the Silicone paint Köster Silicone Paint White.

Waterproofing terraces and balconies with their own hands video

Effective waterproof materials, properly organized fast water removal from the base, professional installation of multilayer terrace construction - the main conditions for reliable and durable protection of the terrace and balcony from aggressive environmental influence. Thanks to modern building materials, the waterproofing structure is quite realistic to perform with their own hands, and then the terrace or balcony for many years will retain the front view and become a worthy decoration of the house.