How to make a staircase safe. Useful advice Ladder

In rainy or frosty weather, slippery steps of external stairs cause a large number of injuries: bruises, stretching, fractures. The article tells what measures need to be taken to reduce the attendance of outdoor and home stairs to a minimum.

Content

Popular facing materials for external stairs

Granite

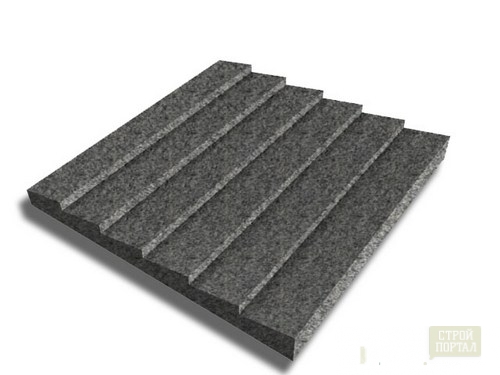

This natural stone is valued for strength and solid appearance. In the design of cruise stairs stores and offices, he occupies a leading position. The most important and, perhaps, the only drawback of granite, especially with a polished surface - high trauma. The method of processing material can reduce or, on the contrary, enhance sliding on the surface.

Ceramic granite

The frequent guest on street facades and stairs of all kinds of institutions. It is not afraid of frosts at all, reliable and attractive. Porcelain stoneware is an excellent alternative to natural material, especially since it costs the buyer cheaper than natural stone. It has the same "sliding" property as granite. The most optimal option for finishing the staircases is considered to be tiles equipped with cutting and embossed strips.

Ceramic tile

This facing material has high frost-resistant qualities and enviable durability. For decoration of the staircase, the most successful option is the clinker tile. This is an artificial stone material from clay, which has passed long heat treatment. A matte surface with a relief image makes it possible to significantly reduce the trauma of such a coating. The embossed texture of the clinker tile is achieved due to the abrasive material, which is applied to it by spraying.

Safe staircase is real

In order to maximize the lesion of the staircase staircases, you need to improve the quality of the clutch of the shoe soles with their surface.

Processing of granite surface

- Ground and slightly "melted" will become granite steps after heat treatment with a high temperature gas stream (about 600 ° C). The heat destroys quartz and makes the surface less porous. After such a processing, the color of the stone is to some extent loses the initial brightness, but the steps become less slippery than they were before.

- Processing by the method of bucharding. With the help of a carbide tool, granite grip, affecting about 0.5 mm of the surface layer of stone. It makes the stone rough and well warns sliding. For the aesthetics of the appearance, it is not treated with the entire surface of the stage, but a strip of a width of 50 - 70 cm.

- The slug - the grinding of the granite, in the process of which the pores of the stone opens, the surface acquires mattness, the color is largely muffled, although the natural pattern of the stone is well visible. The effect of the gluable texture is achieved by treating a grinding circle with a thin abrasive spraying.

- The result of the processing of the granite stone with a sawing becomes a rough surface with longitudinal grooves - traces of metal fraction. Thanks to the steel abrasive material, a relief is created with a high decorative type of invoice. Rubber tabs that increase the clutch of the sole with the surface of the step are installed in the propylene niche.

Processing ceramic granite

In order not to break your head over how to make a slippery porrite surface safe, it is better to immediately get a relief facing material for the stairs. For example, Italian manufacturers (MAPEI, CERDOMUS, LITOKOL) purposefully produce tiles with abrasive inserts specifically for facing steps.

Ordinary porcelain stoneware can only be used if you will enable the safety of the stairs. Methods for treating ceramic granite as a whole are the same as those used for natural granite:

- Polishing with abrasive tools.

- Polishing by rugging.

- The use of porcelain stoneware without polishing after firing.

- Application on the surface of embossed notes.

Processing ceramic tile

In the process of masonry of ceramic tiles on the stairs stage, close attention is paid to the outer corners and edges. High-quality angular and edge compounds of these parts reduce the structure of the structure as a whole. Also significantly reduces the possibility of slipping the soles from the tile stage with a corrugated or rounded edge. When laying it, it is put forward from the edge of the sticky so that the shift is equal to the thickness of the tile tile. Even the rain will not be able to make such steps slippery.

SURESTEP - Confidence Technology

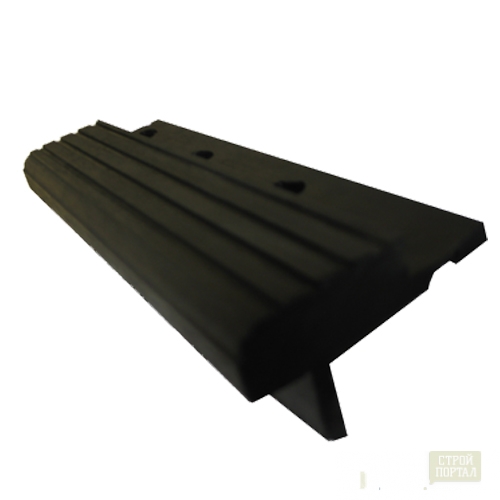

The use of SCURSTEP technology (translated from the English "Sure Step" is a confident step) - one of the most sought-after design options for street stairs. This is a narrow elastic strip of frost-resistant rubber, which is attached to the edges of the steps. Very elastic and stable, it easily opposes even ice crust. Profile, experiencing a load, begged and returns to the original position. Such a plastic breaks down, and purifies the surface of the sheurstep.

To pay attention to when buying and installing SURESTEP.

- Profiles are solely black for considerations of versatility and good visibility on the surface of any shade and color. The strips of another color do not guarantee the availability of the qualities stated by this manufacturer.

- The profile is equipped with special attachments that "hide" under the tile, thereby reliably holding the rubber strip on its surface. This means that when installing, I will first be fixed by Schurstp, and on top there are tiles, which should have a width of less than 10 cm.

- Implement Schurstp Pizza. The length of one part is 118.5 cm. You can combine several details of the jack, if the length of the porch steps is greater. The rubber profile is quite flexible so that if necessary, give it a semicircular or zigzag form.

Anti-slip thresholds for stairs

The design is a worthy competition of Schurstep. Durable and at the same time, elastic plastic with a metal base is attached to the tile during its laying or put on ready-made steps.

Anti-slip scotch

Requires minimal monetary and time costs. Abrasive film with an anti-slip effect is easy to operate: cut the strip of the desired size with rounded corners and apply in the place of the most likely drops. The only drawback of Scotch is a short time, it is enough for one season.

Heated staircase steps

The cable external heating system not only practically eliminates potential injuries, but also protects facing materials from adverse weather conditions. The loop cable is placed on the surface of the steps, pre-placing the heat insulating material under them to reduce heat loss and and electricity consumption. On the promotion of the cable turns evenly adjust to the edge of the stage - it provides fast and complete destruction of snow and sleep. The heating system is fixed with a screed and hide under the facing material of the steps.

Requirements for temples

The staircase railing is appropriate when the stair march has more than four steps. For the integrity of the design of concrete, brick and stone stairs, the handrails of metal are mainly used - steel or aluminum. For safe movement, the fence should reach 0.8-1.0 m in height (taking into account the parameters of adults). Twice below will be auxiliary railings for children if their installation is provided. To eliminate the probability of injury, any deformation of the fence (chip, the formation of sharp parts) requires immediate recovery.

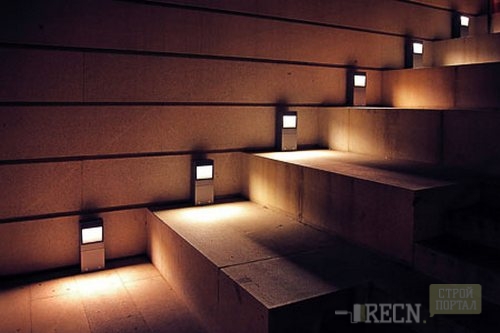

Lighting

It is not necessary to question the relevance of decorative lighting - any, even the most convenient staircase becomes potentially dangerous in the dark. The optimal option for the lighting of the steps is the low lamps installed on the edges of the staircase march, directed to the floor.

Safe staircase for home: What is she?

The ladders of the second floor estimate not only in appearance. Priorities consider such indicators as security, convenience and practicality.

- From 30 to 45 degrees - the optimal range of slope, with which the stairs provide compactness and safety.

- If the stair march contains more than three steps, the presence of the railing is required. Over the entire length of the stairs, the height of the handrail should be 80 - 100 cm. Balasines are placed at a distance of 15 cm from each other. If the stroke of a balaasine is less than 5 cm, two support racks may have to each step.

- The most convenient height of the steps is from 15 to 17 cm, width - 30 cm.

- The distance between the wall and the fence should not be less than 4 cm. The distance between themost steps and the ceiling is about 2 m. The smallest depth for the rotary steps is 10 cm.

- If there are children in the house, the risers are better to close. It can be a material from a tree or transparent strong glass.

- Steps are made from materials that prevent a possible slip: rough tile, matte or embossed stone. In order not to give up an attractive polished surface, you need to get a special self-adhesive rugs. Relevant on the steps will be a reliably fixed carpet.

- Significantly reduces the risk of injury to the light color of the steps and the additional backlight of the upper and lower steps in the dark.

New comments

Add a comment

To send a comment you need authorize.

Hello!

Please tell me that you can lay on the edge of the laminate or parquet board. I would not like the thresholds of black. Thanks.