Folding Roof: Photo, Dignity, Mounting Principles Building materials

Folding roof confidently enters the fashion. It is appreciated for high quality, excellent level of protection, exceptional reliability. The folding roof is an integral part of such an architectural direction as Russian classicism. Therefore, this kind of roofing systems often use this type of roofing systems. But even with new construction, the roof of folded sheets is often carried out. These are usually pitched roofs with a minimum angle of 3 degrees.

Content

What is a folding roof

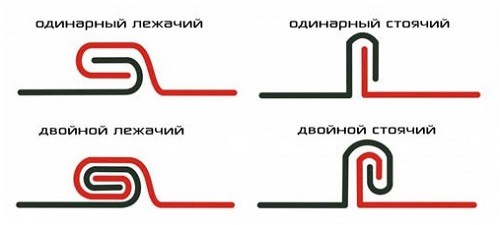

To better understand what a folding roof is, to begin with, it is necessary to deal with the concept of a folding connection. This is a special type of seam, which is formed as a result of fastening the elements of the roof. Distinguish between standing, lying, double and single seam.

Long longitudinal strips are connected along the edges of standing fold, and horizontal elements - lying. You can manually close the connection or using special devices that we will tell you slightly below.

Installation of a modern folding roof is carried out by means of a self-shocking fold, which at times accelerates and facilitates work. On a separate sheet there are edges that are already prepared for folding attachment. Double standing fool is the most reliable connection.

Folding roof is a coating of metal sheet elements interconnected by falothing. This type of roofing system is considered one of the most reliable and durable. The history of its use has not one hundred years, but geography - all countries from the UK to Russia.

But the most noteworthy is that the technology of mounting the folding roof has practically not changed since the moment of the invention, but only improved in accordance with the spirit of time. This type of roof can be called universal for any era and any architectural style - the folding roof is perfectly suitable for mysterious Gothic, and for European classicism, and to create modern stylish structures.

Video installation of a folding roof:

Advantages and disadvantages

The history of the use of a folding roof lasts for several centuries, so all the advantages and disadvantages of the system have been carefully weighed.

Advantages of a folding roof:

- The use of durable corrosion resistant metals.

- The absence of through fasteners, as a result, the tightness of the coating.

- Resistance to deformation of the carrier elements of the building. After fixing the sheets to each other, the roof is a practically monolithic indiscriminate structure.

- Fold technology can be used to cover roofs with a complex configuration, a small slope and almost unlimited quadrature.

- If only double standing fool is used for connection without horizontal or different technological holes, the roof will be completely sealed.

- Saving roofing material, which is especially relevant for complex roofs.

- Fold roofs are resistant to sharp temperature differences and can be used in any climatic zones.

- Unchanging anti-corrosion throughout the life.

- Weight weight compared to other roofing materials.

Unfortunately, the technology has its drawbacks. So, make a folding roof with your own hands will not work without professional skills, equipment and technology. Since metal sheets have high thermal conductivity, to create a comfortable microclimate indoor, it is necessary to carefully insulate the roof and ensure the correct device of roofing cake.

Since metal sheets are used for the manufacture of folding roofs, during the rain there is a lot of noise. Therefore, it is recommended to organize additional nodes and high-quality sound insulation of the building. In mandatory, it is necessary to establish a snowstorming design to prevent the risk of avalanche snow from the roof.

Mounting specificity

As it was already possible to understand from the foregoing information, even the most detailed instructions for installing a folding roof will not help make high-quality coverage without specific skills and equipment. Metal sheets require careful, but intensive processing, and the creation of folding fastenings is not at all without at least minimal skills.

If you are not a professional roofer, you should still have at least some idea of \u200b\u200bthe tools for mounting a folded roof. This will help you determine the level of professionalism of hired workers, and also understand why the cost of installation services is so high.

Tools for mounting

In total, in the arsenal of a professional roofer, you can count more than 40 items of all kinds of tools required for installation: a folding hammer, a molding, scissors for metal, mandrels, mites, various pliers, etc. But all these tools will not help organize a folding roof without a special device to create folded nodes.

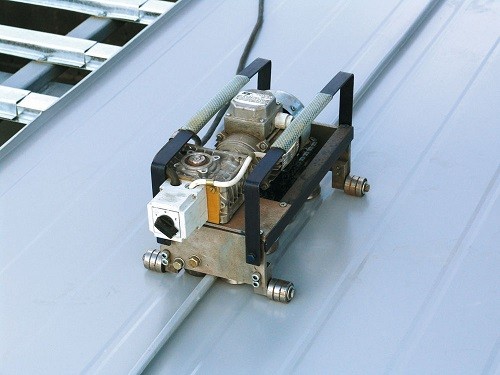

There are three types of machines to create a folded seam:

- Manual - also known as "Frame" or "Hap". This is a separate device creating a folded knot in two steps. Despite the seeming labor complexity of the process, the manual machine is indispensable when installing the roof under a large slope or with non-standard configuration.

- A semi-automatic is a machine that is installed on the place of the future seam and stretch over it with a cable. As a result, the device reserves the finished double standing fool. The use of this device significantly improves productivity compared to hand type. Another advantage of the "semi-automatic" is that it is much more careful effect on the polymer coating of the metal than "Hap". The optimal option for the use of this typewriter is laying long skates.

- Electric - modern devices that save the mass of time and forces of the brigade of the roofers, bring the human factor to a minimum. The device is installed at the place of the future node, include and watch the same moves and fastens the workpiece into hermetic double standing folding. Despite the obvious superiority of electromasters for folding, their choice is quite limited. So, on the market you can find the two most popular models of Flitzer and Piccolo from the German manufacturer of Schlebach. The first option is more economical, but Piccolo has additional features - it can do M-shaped fold on the facade, work with arched roofs, has an additional set of roller rollers. But at the same time the cost of Piccolo is almost 1000 euros more.

Quality, durability, appearance, and indeed all the characteristics of the folding roof dependely depend on the professionalism of the stacker masters and the equipment used by it. It is for this reason that the device of a folding roof costs so expensive, but even your grandparents can enjoy the result.

Copper folding roof

As materials for the manufacture of a folding roof, only some types of metal sheets are used. Copper roof is the most popular, albeit a lot of money. This noble metal will serve without repair and special care is not one hundred years, pleaseing households not only with warmth and comfort, but also a magnificent appearance.

The advantages of the roof

Even those who neither do not understand the properties of metals, heard about durability and exceptional qualities of copper. The copper roof will be able to simultaneously be at a time of 150 years or longer. This non-ferrous metal is capable of completely independently protect against the destructive effects of the external environment. So, in the process of copper oxidation, a specific film is formed on it, also known as "Patina". It is she who serves as a reliable barrier that protects red copper from corrosion.

What advantages, in addition to durability, has a copper folding roof:

- Waterproof - properly mounted copper roofing will not give anything.

- Environmentally friendly material - moreover, copper is able to restrain the pathogenic microflora and create a favorable energy background.

- High thermal conductivity - copper perfectly withstands sudden temperature differences and is not deformed unlike many other metals. If you install under the roof cable heating, snow will not accumulate in winter, and you will not need to spend money on snowstorming devices.

- Plasticity - copper easily takes almost any shape, especially if an experienced master works with it. That is why copper folding roofs are distinguished by a variety of drawings. We will tell about it in more detail a little later.

- Aesthetics or even elitism, if you want. The copper roof on the house testifies to the prosperity and good taste of its owner. The aging of copper is similar to the aging of expensive wine - over the years it becomes only better and more beautiful. In the first few years, the copper coating darkens a couple of tones, then becomes matte black. Gradually, green shades are started on the surface, and after 10-15 years of operation, the copper roof acquires a noble malachitic color.

The only drawback of the copper roof can only be considered that its high cost, but if we consider the fact that in 150 years the roof can never be repaired, it turns out that it is a very economical option. The approximate cost of the copper folding roof ranges from 65 to 70 cu. per square. m. (ordinary sheets without patina).

Picture options

Despite the regularity of global financial crises over the past few decades, the popularity of copper roof does not experience the slightest recession. On the contrary, more and more manufacturers seek to satisfy the demanding tastes of consumers. In this regard, the copper roof can satisfy any preferences - an elastic supplementary surface with ease takes any forms and allows you to create bizarre textures.

The most popular types of textured sheet copper for the roof:

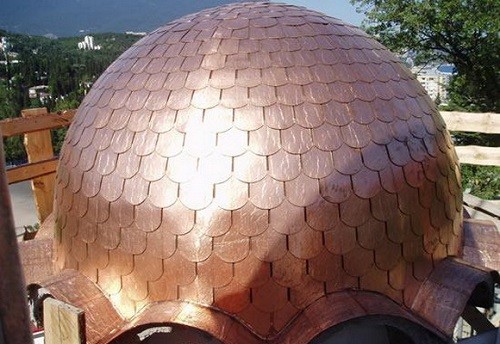

- A checker is a traditional pattern of copper roof, which is very often used in the construction of domes of Orthodox churches. Standard sides of the side of the square of the checkers are 50-60 cm. The sides have a slightly curved form to create a dome bulk effect. The roof is fastened to the top of the roof. There are several types of coatings depending on the color: classic yellow, oxidized brown, malachite or tinted copper, which always remains a matte gray shade and does not oxidize thanks to the tin spraying.

- The bulk checker - the cost of the roof with such a pattern will be slightly higher, since efforts and manual labor on its creation was more spent. However, a powerful visual volume and an unusual appearance justifies any costs.

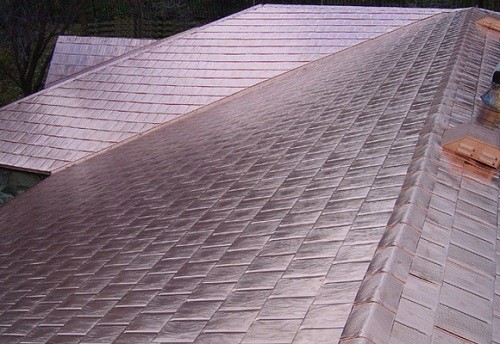

- Rhombus is the same "checker", only with unequal diagonals. The rhombus is often used where the design obliges to emphasize the verticality and stretch of the roof. The dimensions of the rhombus can be completely arbitrary at the request of the customer.

- Volumetric Rhombus (Lemeh) - often this drawing can be found on rich temple domes. Previously, this texture was used exclusively for the construction of religious structures and tsarist palaces.

- Scales are very beautiful texture, but unfortunately, very impractical. The scales weakly protect against precipitation, so it is better to use it as a decorative roof. In addition, it is beautifully lay out the scales, professional skills and extensive experience are required. The slightest offset on one of the lower rows, and the whole composition will turn out to be a curve.

- Brick - pretty simple and unassuming from the first sight of the equipment. This texture is used not only to create a roof, but also for the decorative finish of the facades. There are ordinary and bulk types.

Manufacturers of folded roof

Today, the manufacture of a folded roof from copper is carried out by many firms, both in domestic and foreign. Deciding to acquire such expensive and elite material, you should give preference only to proven manufacturers with a multi-year and impeccable reputation.

The most popular producers of copper roof:

- KME (Germany) is a real mastodont among European manufacturers.

- Luvata (Finland) - the company is known for its unique technology, which allows you to produce copper sheets with original surfaces and textures.

- Gai ZOTSM (Russia) - the plant also produces copper tape on its own technology, to enable a patina in 2 times faster.

- ZOTSM Artemovsk (Ukraine) - production nepatirovannyh copper sheets.

FEATURES OF MONTAGE

Mounting technology seam roof of copper sheeting requires careful and at the same time intensive treatment, so the cost of the work exceeds the price of other materials installation of approximately 30%.

In 2014, the average cost of installation of copper roofing nepatirovannoy varied from 20 to 25 USD 1Q. m. Price sheet stacking patina calculated separately, depending on the complexity of the design and characteristics of the roof.

Aluminum seam roofing

Aluminum is reliable, admirable durability and resistance to damaging environmental influences. But can we say the same thing about aluminum standing seam roof? Aluminum has many advantages, which will undoubtedly impact on the operational characteristics of seam roof. It turns light, durable, very easy to clean and attractive appearance.

Advantages of aluminum standing seam roof:

- high corrosion;

- resistance to ultraviolet light;

- fire resistance;

- durability (average service life of about 50 years);

- flexibility (good looks and a country house and public building in the city center);

- can be mounted on the roofs of any configuration;

- ease of installation;

- due to the low weight of aluminum sheets is not necessary to install powerful bearing designs, which gives an opportunity to save and reduce construction time;

- low cost in comparison with other types of standing seam roofs.

Deficiencies in seam roof made of aluminum is not more than the rest. For an objective assessment should be added, that factors such as noise during rain, snow melt winter, aesthetic performance and low impact resistance in mind are not taken. These "flaws" are caused by physics rather than real flaws associated with standing seam roof technology. The high cost is caused by the specifics of work, but, nevertheless, is lower than the price of copper roof.

The only thing that really is worth stopping attention is low impact resistance. Aluminum is not able to withstand a serious load and may interfere. If you want the roof of your home to keep the original appearance as long as possible, you should not sit nearby. High fruit trees, otherwise the apples or peaches falling in autumn will leave dents.

Summing up, it can be concluded that the aluminum folding roof serves as a reliable protection for the house, even if not so durable as copper. At the same time, it is quite economical, neat and does not require much care.

Galvanized folding roofing

The metal folding roof from the zinc alloy is capable of listening almost as long as the copper, without requiring major repairs. Few people know, but the first alloy of zinc with copper, also known as brass, was popular in ancient Greece, China and Egypt. The only problem was in his brittleness, but this lack scientists quickly corrected, adding other metals to alloy. Today, the titanium-zinc alloy is one of the most sought-after, by 99.995% consisting of zinc, 0.05% of copper and approximately 0.09 - from titanium. This is extremely durable and resistant to corrosion metal, which has found application in many industries, including the construction of folding roofs.

Advantages of galvanized folding roof:

- Durability - operational period without overhaul is about 100 years.

- Corrosion resistance - metal itself is not susceptible to rust, and due to the folding technology of the compound, it guarantees quality and impermeability over the entire period of use.

- A small weight allows not only to speed up the deadline for the installation, but also to save on the transport of material.

- Waterproof - double folded seam in combination with a solid metal ensures the tightness of the roofing coating.

- Aesthetics - an attractive appearance harmoniously fits into any landscape and is suitable for any architectural style. During operation, the surface is covered by a protective layer of patina like a copper roof. The formation of an "luxury flying" occurs pretty slowly, and this may take several years, but modern technologies allow you to significantly speed up this process. Applying a special oxidizing composition allows you to quickly get the desired noble patina effect.

Of the rational drawbacks of this roofing material, it is possible to distinguish anything to the demanding to gentle storage and transportation. Sheets should be carefully protected from moisture ingress while they are in the factory packaging. Otherwise, they are formed by an immemorated white raid in places in contact with sheets, which will spoil the appearance of the roof.

About manufacturers

Since the galvanized folding roof is the second on the high cost after the copper, it will be very disappointing if you are selling poor-quality material, so it is important to choose a proven manufacturer.

Among foreign and domestic producers of galvanized blood reliability and excellent reputation are characterized by the following:

- Rheinzink (Germany) is a leader among similar firms in the global market. It has more than 30 subsidiaries in the world's largest countries. According to the manufacturer, the service life of its roof is 100 years and more without additional specialtenance or repair.

The company offers a choice of several types of titanium zinc: glossy, gray-blue, dark gray. Brilliant gloss will cost the cheapest. These are sheets without patina, which "earn" it with time naturally. The gray-blue sheets stand just more expensive as they are already patched. Dark gray galvanized sheets are covered with a thick layer of patina, look very noble and cost more. - Nedzink - plants are located in Belgium, Germany and Holland. The company is known since 1973 and manufactures not only excellent roofs, but also facade and drainage systems.

- VMZINC is a Belgian company producing zinc-titanium sheets that meet unified European standards. Luxury products known for very long operating deadlines.

The need to install a folding roof occurs only from those owners who seek to build a reliable, comfortable and, most importantly, durable housing for themselves and its descendants. Once in carrying out a large amount in the construction, you can forget about the leaks, repair of the roof or annually appearing cold bridges.

The most ambitious folding roofs of the world

In conclusion, we suggest you admire the most beautiful, large-scale and unusual folding roofs.

Donbass Arena Stadium, Donetsk, Ukraine:

Dome over the reactor Chaps, Ukraine:

Ski resort Ski Dubai:

Fantastic aluminum folding roof (photo) of Ferrari Entertainment Park WORLD ABU Dhabi:

The following photos are irrefutable evidence of durability and high quality folding roofs.

Cologne Cathedral, Germany:

Noyshivstein Castle, the image of which served as the starting point for creating the Disney logo:

Cathedral of Parisian Our Lady:

Westminster Palace, London:

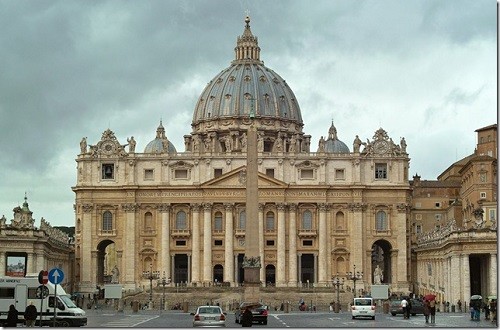

St. Peter's Cathedral, Vatican:

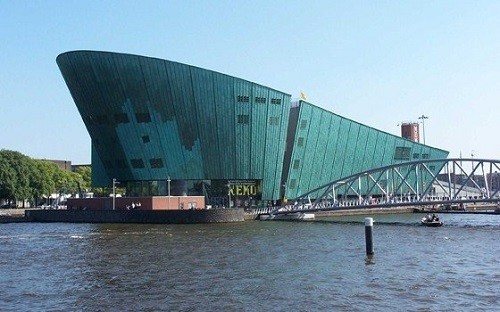

Amsterdam is known for its original architectural solutions, one of which is a scientific museum, a metal-sheathed metal.

Returning to the native edges, observe the magnificence and the quality of the folded roof, while looking at the luxurious Ekaterininsky Palace and Hermitage.