Liquid thermal insulation Corundum: characteristics, advantages and disadvantages Insulation

The preservation of heat indoors largely depends on the thermal insulation parameters of the structure itself and the finishing materials used. I reliably insulate the house - it means to reduce the cost of heating. Today, the construction industry offers many varieties of insulating materials that differ in their characteristics and cost. One of the most optimal options is the liquid thermal insulation of corundum, which is distinguished by durability and excellent thermal insulation properties. Consider more detailed features of the composition, the criteria for choosing and applying the technique.

Content

- Features of Ceramic Heatlook

- Liquid thermal insulation Corundum: Specifications and principle of operation

- The advantages of thermal insulation Corundum

- Disadvantages of superflux heat-glass corundum

- Major types of thermal insulation

- General criteria and selection features

- Application area

- Ceramic Isolation Application Technology

- Conclusion

Features of Ceramic Heatlook

The unique composition of thermal insulation is also called heat-reflecting paint, since with a layer thickness, only 1 mm is capable of providing a noticeable effect of energy saving. Due to this, the thermal insulation of corundum on consumption is very economical. The filler includes microscopic hollow spheres - ceramic, polymer, composite, glass balls, which are filled with sparse air. Such microparticles can be varied not only in composition, but also in size microgranules, percentage ratio, homogeneity of components, etc.

Externally, ceramic ultra-thin paint is practically no different from conventional acrylic paint. Despite the fact that today the construction market offers several types of hyperfine insulation compositions, almost all of them have a similar structure:

- Based on thermal-acrylic solution. Its properties allow you to ensure the uniform distribution of thermal insulation components on the working surface. In addition, the composition contributes to the best fixation of liquid ceramics.

- Also, the binder contains different kinds of additives that improve the operational parameters of the heat-glass. The most common supplements of the material include natural and artificial rubber, silicone, etc.

Liquid thermal insulation Corundum: Specifications and principle of operation

The temperature range for thermocracy varies in the range from -65 ° C to + 260 ° C. The main technical characteristics are vapor permeability and hygroscopicity of liquid isolation, which can be applied to almost any type of facade material: concrete, stone, brick, metal, plastic, etc.

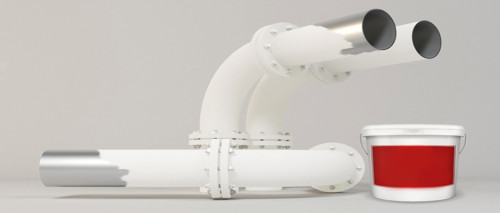

This material ensures the removal of condensate, which is formed on the walls and pipes indoors. Such a heathed includes special locks, catalyzing substances, anti-corrosion additives, as well as a binding base on high-strength acrylic. Along with the content of the microspheres, this composition is easily applied and distributed over the entire surface, providing good indicators of energy saving and thermal insulation.

An important argument to buy liquid thermal insulation Corundum is the safety of matter. Due to the content of natural additives and environmentally friendly components, the treated surface is not toxic and does not distinguish any odors. This allows you to use heatcharacy to isolate any premises. You can create a resistant thermal barrier, even in children's rooms or housing, where allergies are located.

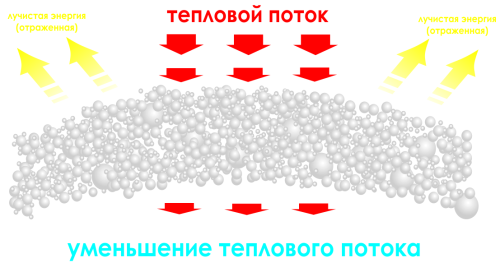

The thermal insulation properties of the composition can be achieved in several ways:

- By convection, i.e. heat transfer by the heathed layer itself. Due to the fact that most of the specific weight of the liquid isolation consists of hollow balls, the loss of convection in the composition is completely insignificant.

- Thermal conductivity of the material when heat is transferred from a heated side of the surface to a colder place. In liquid insulation, only 20% of the binder component possess the properties of thermal conductivity.

- The radiation is a phenomenon at which heat transfer occurs by means of the internal energy of the suspension. In energy-saving paint, microscopic spheres are endowed with the properties of reflection and dispersion of heat. Almost 90% of the reflected radiation turns the working surface of the wall into an analogue of the thermos.

The advantages of thermal insulation Corundum

Liquid heat-saving paint is an innovative composition, which differs from all existing coatings. Among the most significant advantages of its use, such aspects should be allocated:

- Universality of the substance. It can be applied to any type of surface, including unprocessed, if this is the instructions for use. Experts use heatcharacy to treat brick, concrete, metal, plastic surfaces, as well as thermal insulation of equipment and air ducts.

- Wear resistance. The applied layer of liquid isolation does not degrade with time. Corundum provides a guaranteed life of up to 15 years, and with competent care (timely cleaning, high-quality finishing), this indicator can be increased twice.

- Ceramic thermal insulation has good adhesion with any type of material, which ensures good protection against moisture and air intake.

- The substance is resistant to alkaline medium.

- Liquid thermal insulation provides anti-corrosion protection and minimizes heat loss.

- The dry coating of Teplokraskaya reliably protects the treated surface from deformations due to temperature differences, atmospheric influences and moisture formation.

- Ceramic thermal insulation is practical and easy to apply on the surface of complex geometric shapes.

- The super light material, which does not create an additional load on the design. Due to this property, heatcharask is often used during roof processing.

- The substance is quite convenient in repair, because With minor damage, the old layer can be easily removed by replacing it with a new one.

- Heatroka reflects up to 80% of ultraviolet rays.

- Everything else liquid isolation is resistant to fire. When heated to + 260 ° C, the applied layer is charred, and when the indicator is reached in + 600 ° C, heat-colored begins to decompose, highlighting carbon and nitrogen oxide, which preemptive the rapid spread of the flame.

Disadvantages of superflux heat-glass corundum

Despite the impressive list of merits, it is not deprived of some shortcomings. Among them should be allocated aspects:

- High cost of warmlook.

- Since ceramic thermal insulation is a relatively new product on the construction market, there are no more proven evidence that material meets the declared characteristics.

Major types of thermal insulation

Liquid hyperfine thermal insulation is available on sale specialized construction stores in several versions. The entire line of polymer compositions consists of such species:

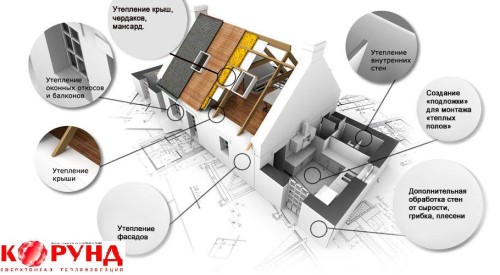

- Thermal insulation Corundum Classic is a liquid suspension, which is intended for roofing and facade works. Also, this composition was used in the interior decoration, ensuring reliable thermal insulation of walls in residential buildings and general-purpose buildings. In addition, the classic variety is highly effective for isolation of concrete floors, bulk coatings, communications of hot and cold water supply, as well as the insulation of window slopes.

- Corundum Anticorrosive is a special composition of the anti-corrosion destination, which is allowed to apply simply on a rust covered surface, without special processing. Such thermocrash is characterized by high adhesion indicators to concrete and metal, creating a reliable protective and insulating layer. As a rule, this liquid thermal insulation Corundum is price somewhat cheaper than the classic type and is used to create the first base layer of insulation.

- The facade is a type of heat-saving paint intended for the processing of concrete surfaces, as well as buildings from slag-or foam blocks. The composition is applied with a thickened layer, thereby declining the coefficient of labor costs for the processing of surfaces of a large area. This type of heathed, as a rule, is used for finishing finish.

- Winter is a liquid thermal insulation designed for work during the cold season. The principle of energy saving is based on the "thermal mirror effect", i.e. Reflections of streams of heated air masses. This composition is universal and is applied to almost any surface at ambient temperature to -10 ° C.

General criteria and selection features

Ceramic heat insulation is not yet a fairly common type of coating, which is due to the high cost of products. However, experts argue that this substance has exceptional performance, whose value is significantly superior to the cost of acquisition. To choose the optimal type of liquid thermal insulation, it is important to take into account such features:

- The first thing that affects the final result of treatment with ceramic insulation is the density of the composition. High-quality heatcharak is characterized by an indicator of about 0.6 kg per 1 liter of product. Those. The weight of the standard bucket on 10 liters should not exceed 7.5 kg.

- It is also worth viewing a container with a solution "on the lumen" to determine the degree of its bundle. A good indicator of the quality and effectiveness of thermal insulation properties will be a dense upper layer of substance. As a rule, ceramic spheres have a slight fraction that rises upstairs. Thus, the thicker the upper layer is the higher the thermal insulation properties.

- An equally important criterion of choice is the structure of the suspension itself. To determine it, it is necessary to lose a couple of droplets of warm-oil between your fingers. In high-quality composition, micrographs of ceramic balls are felt, i.e. The substance has roughness.

- In addition, it is necessary to take into account the color of liquid heat insulation. Corundum is produced in white, so the paint of a gray or yellow shade is an explicit certificate of fake products.

Application area

Ultra-thin ceramic isolation Corundum - Innovative material that forms a solid elastic coating, reliably protecting the surface from moisture, overheating and corrosion. This composition is used at a temperature range from -65 ° C to + 260 ° C.

The main areas of application of heat-oil include:

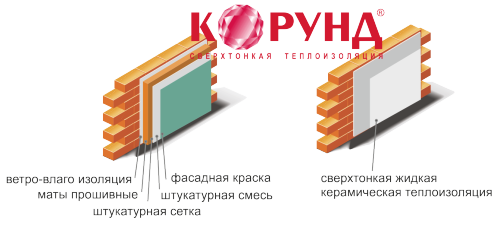

- housing and utility facilities (including processing of pipelines of various purposes, thermal insulation of facades, roofing, windows, walls);

- transport industry;

- petroleum industry;

- insulation of heat and power structures;

- construction industry.

Ceramic Isolation Application Technology

Apply an ultra-thin thermal insulation of corundum is needed on a pre-prepared surface, regardless of the modification of the composition. The main rules that should be adhere to before the start of painting insulation include such:

- If the ceramic insulation is designed for processing walls, the working surface should be cleaned of dust and contaminants, and the available gaps and chips should be sized and fill in cement mortar.

- Before performing painting heat insulation on concrete slabs, they should be cleaned from "cement milk".

- It is also necessary to handle the wall with an abrasive circle, sandblasting machine or a rigid metal brush.

- If we plan to process a metal surface, it must be discussed and degreased (recommended by the producer of substance - solv-ur, solvent). For painting of non-ferrous metal items, it is necessary to remove the gloss and applying the soil composition of VL-02 or VL-023.

- It is also worth considering that it is necessary to breed a ceramic heatcharacy directly before applying to the wall.

Important! The mixing of the liquid thermocracy Corundum is recommended manually. However, for work with large volumes, the use of a construction mixer is allowed, the speed of rotation of which should not exceed 200 revolutions per minute. Otherwise, the risk of destruction of hollow ceramic granules is arising, which will negatively affect the properties of the thermal insulation of the composition. As a rule, the manual mixing takes 10-15 minutes. When working a building mixer, this indicator will be 3-7 minutes.

It is also worth considering that in some modifications of the composition before starting work, it is necessary to add water, so you need to carefully examine the manufacturer's instructions. The volume of fluid depends on the purpose of thermal insulation, in any case, the required proportions are indicated on the packaging of the composition.

The technique of applying ultra-thin thermal insulation Corundum is carried out in three ways:

- using air spraying devices;

- airless spraying method;

- manually - with roller or brushes.

The manufacturer recommends the application of the composition in three layers, while the consumption must be 1 m / m 2. When working on thermal insulation, this composition does not require an additional influx of ventilation indoors, as well as the use of special means of individual protection.

For guaranteed performance efficiency, it is important to strictly follow the manufacturer's instructions and fully adhere to the recommendations specified on the package.

Conclusion

The use of ceramic heat-insulating is an innovative approach that has indisputable advantages in front of traditional methods of thermal insulation of surfaces. The article discusses the main features of the liquid thermal insulation of corundum, reviews, selection criteria and composition of the composition. The resulting coating layer is ease, excellent performance and simplicity of use.

Features of the choice of liquid isolation corundum. Video: