How to make an arched window Window

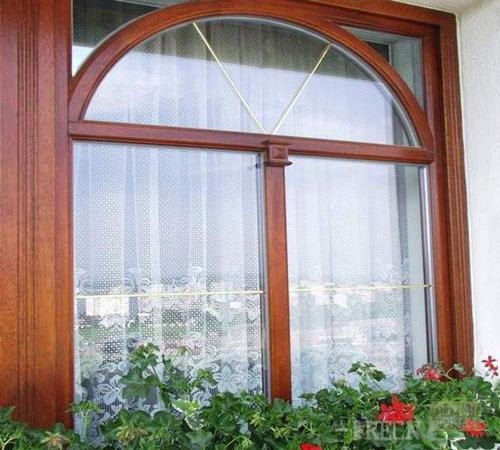

Increasingly, people, elevating country houses and giving, express the desire to establish arched windows. According to functionality, they are not inferior to usual, but at the same time they look very impressive.

Content

Types of arched windows

Arched windows, the photos of which you probably have repeatedly seen, are classic and arcuate. Consider them in more detail:

- Often, classic arched windows, called the people of "sunny", are installed in the doors, bathrooms, on the roofs. They have a round shape and equipped with spokes, something similar to the sun's rays. Such windows are very popular and allow you to give the house an unusual look.

- Arched arcuate windows are a conventional rectangle, the upper side of which is rounded. This option looks more beautiful than the previous one, but at the same time it is very easy to use. Most often, such windows are installed in large homes, but also in the country cottages, they also look good.

Arched windows are not just a hole in the wall opening the access of light into the room, but also a peculiar element of the decor that gives the house is an elegant and meaningful look.

According to the manufacturing material, such window structures are divided into wooden and plastic. Arched PVC windows are:

- strelded - meet in the Gothic Councils;

- semi-curvous, who decorate the Orthodox churches;

- moorish, reminiscent of horseshoe.

Arched plastic windows are deaf and open, can have all sorts of radii and angles of inclination.

The palette of colors of plastic frames is extremely rich. They can imitate the color and structure of the tree, have a classic white, beige or gray color suitable for high-tech style or be colored and used for non-standard decoration of premises.

If you want to have a large arch-arch in your house, then at the design stage, be sure to calculate wind, dynamic and static loads that will have to have it.

Arched wooden windows are the following forms:

- circular having a complete radius;

- truncated;

- having two radius;

- strengted.

Just like plastic, wooden windows are deaf and opening. At the request of the customer, they are equipped with various decorative elements, such as bindings and rays, and also embed one arch to another.

Such windows produced almost from any wood, most often it is oak, pine or larch.

The manufacture of arched windows made of wood is an extremely complex and time-consuming process. Opening mechanisms are as follows:

- folding;

- swivel;

- swivel-folding.

In the production of wooden windows, the mandatory operation is their treatment with antiseptic means, as well as paint compositions specifically designed for window structures. Such paints are environmentally friendly, elastic, have a good coupling with wooden surfaces, are not afraid of UV radiation and temperature surges.

Wooden designs are more expensive than arched plastic windows. The prices of them are higher due to the ecology of natural material.

Advantages and disadvantages of arched windows

The advantages of such window structures include such properties as:

- the ability to create a unique and non-standard appearance of the house, give it an antique effect or just decorate, add elegance to the interior;

- allow you to make a small room visually wider and longer;

- have high strength and long service life;

- high-quality fittings makes it possible to create various elements of scenery;

- on heat and noise insulation qualities, nothing is inferior to standard window structures;

- environmentally friendly, if produced from wood;

- allow you to use any opening mechanism.

The disadvantage is the following feature:

- because Even specialists are very expensive in time and difficult to produce arched windows, the price of them at times exceeds the cost of ordinary, standard windows.

Arched window with your own hands

Arched metal-plastic windows make only production, so consider the process of self-making on the example of wooden.

There are several ways to manufacture window structures from wood. The choice depends on the set of existing tools and skills.

Method number 1:

1. At the initial stage, make a plywood pattern with a thickness of 3 to 5 mm. It will simplify the actions when working with a manual milling.

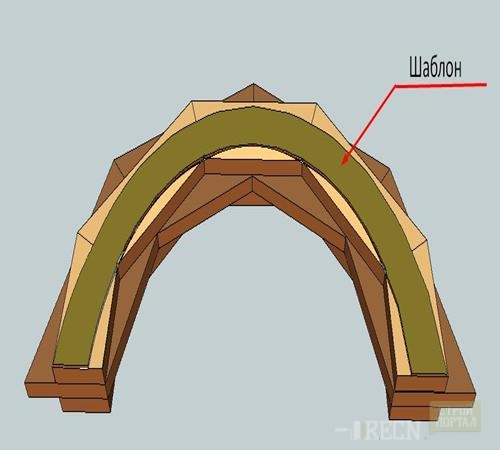

2. Arches produce either of the finished glued bars, or from individual parts folded together and glued by laying bricks. The thickness of these billets or lamellas should be 2.7-2.8 cm. They are glued together and planes, and ends that have a certain corner washed and fitted with each other perfectly. The design is assembled as follows:

- billets of the initial row to put the ends with the coated glue to each other;

- from above, lay out the following row with lubricated glue planes;

- set another row similarly.

3. This three-layer design must be pressed by cargo or compress vice before glue grabbing. An important parameter is the mismatch of joints in neighboring ranks.

4. Next, it is necessary to process glued construction according to the template, and the outer end should be customized for it only approximately because it will strive in the wall of the window opening, but the inner side must be taken with extreme accuracy. For data of manipulations, a mill will be required.

Method number 2:

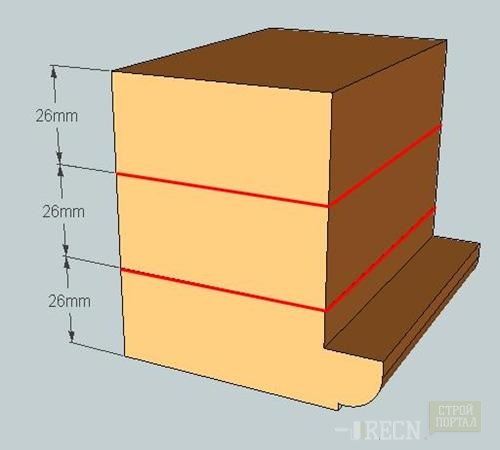

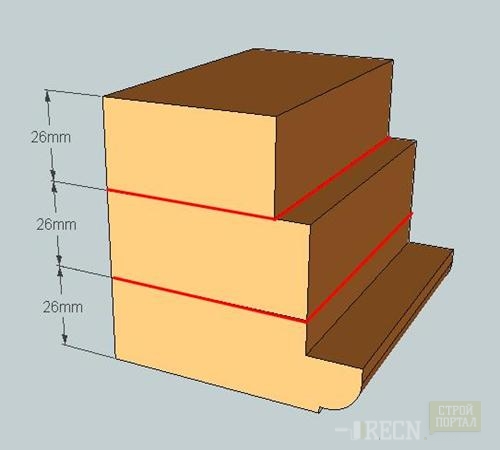

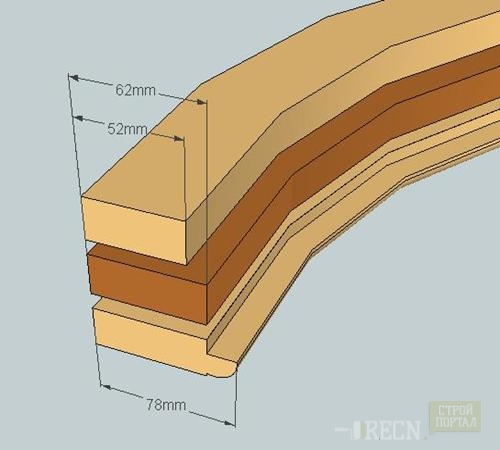

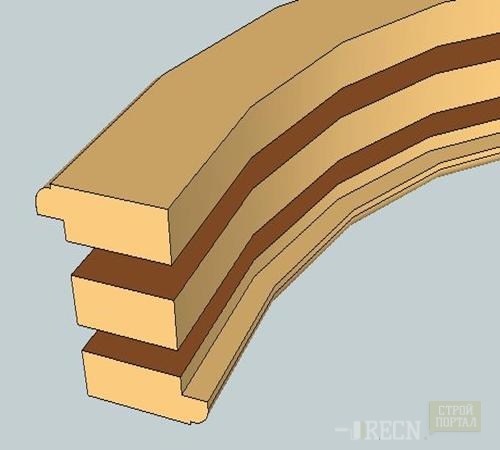

The illustration shows a three-layer profile bar. The first picture displays the end part of the profile, which will be made of a deaf arched fraumuga. The second picture shows the end of the profile, from which the opening fraumug will be made. The red line indicates the layers of layers of the bar.

1. Spread the layer all the lamellas of the future arched construction. It is best to make a template for each of the layers, because They have different widths. When gluing lamellae ends with each other, use either the "plug-in spike" method, or "micro spike".

2. Each of the workpieces process, leaning on the template, in compliance with the rinds.

3. Now take the mill and where you need to make a fold.

4. Create all the blanks into a single arched bar with glue and vice.

5. Acting in the same way, make the opening sash in the arched fraamuga.

6. The endings of the arch component are connectible with the other parts of the design vertically and horizontally with the help of spikes or on the "UC".

How to make an arched window round shape

The round window is performed smoothly in the same way that is described above, only the workpieces in the form of the arch were used, and here they will be in the form of a semicircle.

Billets also consist of lamellas glued with ends. The completed billet after processing on the template should take the form of a semicircle. Each of the layers should consist of two semicircular blanks, which, when combined, form a circle.

All layers are collected in dry and fold on each other, and the sequence must be observed.

The joints of the lamellae shift relative to the adjacent layer, as described above, on the principle of brickwork. After the semicircle is perfectly fitted with each other, begin to glue them.