Installing metal-plastic windows with your own hands Window

Today, perhaps, everyone knows that plastic windows with a double-glazed window have a lot of advantages over conventional window systems. Such windows provide sufficient heat protection and tightness. Therefore, many try to change the old windows to new plastic. You can even install them on your own. After all, such works do not require any special tools. In the process of installation, only adhere to guests, as well as take into account several nuances that will help achieve a qualitative result. Consider the installation of metal-plastic windows with your own hands.

Content

Directly in this process will need to go through several stages, and the first of them is - the window openings. Then you need to dismantle old windows, prepare window openings and install plastic windows. In order for blocks to come better better, it is recommended to apply to a special firm that is engaged in the production of plastic windows and order them according to your sizes.

Should I install plastic windows yourself?

In fact, in this work there is nothing complicated, but still there are the advantages and disadvantages of this approach. On the installation of one window will go on average for three hours. This is relatively few. Over the weekend put all the windows quite real. In addition, in this case, you will save on payment of services workers who are engaged in the replacement of windows. On one window you can save $ 50 on average. Such is the approximate cost of installing metal-plastic windows. Therefore, if you install the windows yourself, you will not worry, how much is the installation of metal-plastic windows.

The main disadvantage of installation of windows with your own hands is the lack of guarantees that give professional installers. In order for the firm to give a guarantee on the windows, they must complete the entire steps of the installation. Despite the fact that there are no standards for plastic windows, there are no standards for the size of the window block. Most often they are manufactured by individual order. If you bought accessories from the same company, which ordered the installation of windows, then you would receive a guarantee for it (from 1 to 5 years). When independent installation windows warranty will not be on the accessories.

Therefore, if you make mistakes when measuring the window opening, the windows can either not fit either to hang out in it. This in turn will only increase the amount of work. In addition, errors may occur already at the stage of installing metal-plastic windows. Due to poorly performed works, you can completely lose all the advantages that plastic windows possess. Therefore, if you want to install them yourself, then you should learn more about the methods and rules for installing metal-plastic windows. Consider more each of the steps of the necessary work in more detail.

Measurement

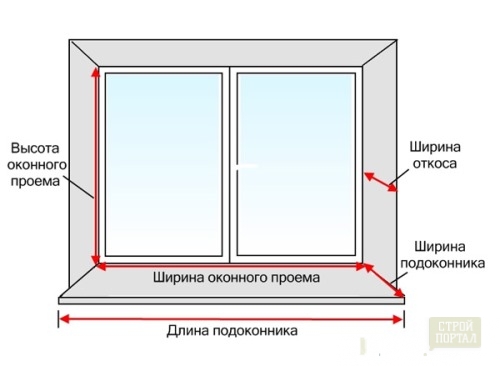

Let's start with the process of measuring the window opening without an exterior quarter. The order of measurement is important. First you need to know the width of the window opening. To do this correctly, you should measure the distance between the two extreme dots of internal slopes. Measurement must be done along the inside of the wall. Then the opening height should be measured. This value is equal to the distance between the upper slope and the windowsill. By this distance should be added to the thickness of the window sill. When the width and height are known, you can count the preliminary dimensions of the window. Thus, its width is calculated by the difference between the width of the window opening (VAC) and multiplied by two magnitudes of the assembly clearance (MW).

Width \u003d Shop - 2 * MH

The height of the window is considered as the difference between the height of the window opening (VB) and multiplied by two magnitudes of the assembly gap (MW) and the size of the supply profile (runway).

Height \u003d HP - 2 * MH - runway

Measurements should be done at least three places for each size. It is recommended to do it at least and in the middle. There are three different measurements. You need to choose a smaller one. In addition to measurements, you need to check the curvature of window openings. To do this, it is best to use plumbers that are well-centered along the axes and have a sufficiently pointed tip. It should also be checked by the usual building level of the horizontal of the distortion.

It is possible that these measurements will show insignificant deviations. Therefore, in any case, all your measurements are displayed on a sheet of paper in the form of a sketch. It should show the correct rectangle, which is inscribed in the contours of the window opening with the actual dimensions. This is necessary for the amendments of the window frame.

Such measurements should be carried out on the window openings in which plastic windows are planned. After all, you will have to order windows one size. It is possible that after all measurements the width of the window openings will be different. The height is usually the same in all over the windows. In any case, you should take a smaller size.

Then you need to determine how the window block will be located. The plastic window is set to about two thirds of the wall width, if you count from the inside. In the event that it is planned to sew the external walls of the building with a heat insulator, then the windows can be put on a greater distance. On the resulting distance will be located the outer plane of the window.

It is also necessary to make a measurement outdoor. To do this, it is enough to make a measurement length, which was installed. You can also take the width of the window opening, which was measured earlier and add 50 millimeters of the bending allowance. To count the hoist width, it is necessary to add the distance from the mounting plane to the outer edge, approximately 30-40 millimeters onto the protrusion and a small reserve for bend. At the same time, if insulation or isolation is planned, then it should also add the size of the layer of the exterior walls to this magnitude.

It is equally important to do the measurements of the window sill. To calculate its width, take the distance from the inside of the wall to the mounting plane, to this distance, you still need to add the size of the departure and from this amount to the width of the window frame. When you measure departure, you need to take into account that the overlap of the heating radiator with a window sill should not be more than one third part of its size. In the event that the radiator is too drowning in the opening, then you can make 5-10 centimeters in advance from the window in the windowsill slots for ventilation. Due to the fact that it is almost impossible to calculate the width of the future window in advance, the slopes are best measled after them. The window length is usually the same as the height of the window opening, but it is necessary to take into account the reserve on the cutting.

As for the measurements of window openings, having a quarter, this process has its own characteristics. Such openings are often located in brick buildings. The measurements of these window openings should be made on the outer part. To calculate the width, it is necessary to add the distance between the quarters (RMLC) from the value of a quarter to the window frame (SCD) multiplied by two. Typically, the occasion is from 25 to 40 millimeters.

Width \u003d RMLC + 2 * VCD (25-40 mm)

The height is considered by adding the height of the opening from the low tide to the upper quarter (VPO) and the approach of the same quarter (ZCh). The size of this approach also ranges from 25 to 40 millimeters.

Height \u003d VPO + ZCh (25-40 mm)

When measuring, you need to always take into account the presence of a screed of cement under the sampling and a windowsill. If you take it into account, then with a large screed thickness it will be possible to install windows having a large area of \u200b\u200bglazing. Calculation of sings and window sills should be conducted from the mounting plane that you need to choose from the inner part of the quarter.

Plastic windows are often put on the balcony. Such blocks have their own features when measured. So, to calculate the width of the window, you need to calculate the length of the support parapet and on each side, the deduction from this value is about 60-70 millimeters. This distance will be needed to install an angular profile, with which it will be necessary to combine the front and side design. To measure the height, the distance from the parapet of the balcony is taken to its roof and the size of the mounting gaps (25-30 millimeters) is subtracted from this value. The side windows on the balcony are made almost as well. Only in width with each of the parties to install an angular profile, it is necessary to subtract 60-70 millimeters, and the gap between the wall of the house and the window should be 25-30 millimeters.

How to choose a window design

When measurements are made, you can make an order from the manufacturer of windows. It is possible that the specialist slightly adjusts your sizes. When the dimensions are agreed, the configuration of future windows is determined. At the same time, together with the company's specialists, you determine whether the window of the sash is needed or the deaf part, and also choose accessories. In addition, at this stage it is important to choose the system on which the windows will be attached. It is most likely to choose from two types of fastening - this is the mounting through the frame in the mounting plane of the window and the mount with the help of supporting reinforcement. In the latter case, the armature must be installed in advance on the frame during the assembly.

The first option is most often used. In this case, it is necessary when installing completely remove the swinging flaps, as well as double-glazed windows with deaf flaps. As for the second option, it is easier for self-installing metal-plastic windows. The price of this type of installation is slightly different. This method of installation is much easier, because it minimizes the risk of damage to the glass package and its tightness in the process of disassembling assembly. True, in this case, when installing the window block, the whole design will weigh quite a lot, which does not allow you to install it alone.

Preparation for mounting

- First you need to wait for the delivery of window blocks, because it does not make sense to spend some work before it. After the delivery of windows, free yourself zone for work. Furniture can be left, and the heating radiator and the floor should be covered with a film or dense tissue.

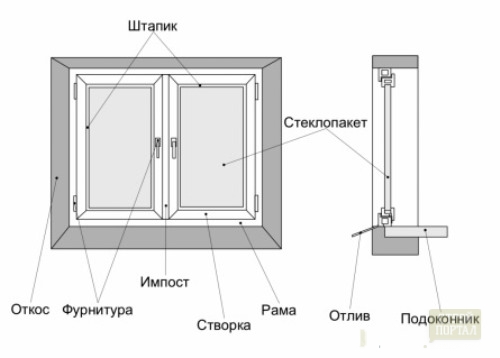

- After that, the window block itself should be prepared. If necessary, you need to remove the glass windows and swinging flaps from the window frame. Double-glazed windows are fastened with the assistance of a stroke. Dismantling can be made using the chisel. It is raised by the Strapist and with the help of non-stamps by the instrument, it is removed from the groove. First you should shoot vertical, and after them - the upper and lower.

- All the strokes are definitely marking to then not confuse them. Then tilt the frame so that the double-glazed windows come out of the grooves, then put it on the wall. If there are swinging flaps, they first remove the decorative plugs, and then you need to unscrew the clamping bolts. If there is a frame system, then the top of the sash should be released using the handle turn as when the sash is opened, and then you need to get the hook from the lower canopy. After that, you should only have a window frame with sharing planks.

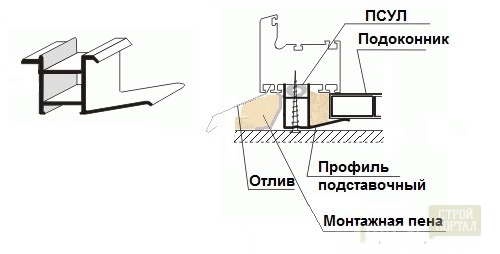

- Now, from the inside of the window frame, you need to do around the perimeter of the hole. They will be needed for anchors of fastening. For holes, you will need a drill on metal. The windows should be fixed using anchor bolts with a diameter of 8-10 millimeters. If the window is attached using special-fasteners, it should not be pre-disassembled. It will be enough to install fastenings on the frame with the help of screws. During the day before installing the windows, you should simulate all the free internal space, which is available in the coaching profile. This will help to eliminate the possibility of forming a warm bridge at the place of attachment of this profile to the frame.

- Immediately before installing new windows, you need to dismantle old. To do this, you first need to remove from the sash canopies. In order to make it easier to disassemble, you need to make a feeder in a few places on the window box and the frame. Then, with the help of the Lomik, each part of the frame is approaching and then removed from the window opening. If there are large nails that hold the window box, then before dismantling you should get them. In addition to the box, you need to dismantle insulation and seals. Sucks depending on your plans can be removed, both partially and completely. For this purpose, a perforator with a nozzle is well suited. Finally, the windowsill is removed, the cement substrate is disassembly.

- The garbage formed after dismantling is folded into special bags and is taken out of the building. You should also bear the old window or what he remains. After that, you need to compose and clean the ends of the window opening, and then be sure to progress the working surface.

Installing the plastic window

- Immediately before installing the new plastic windows need on the lower end of the window opening bed substrate in the form of a special plastic material or a simple piece of wood. It is important that the upper portions of the substrate are in the same plane. They should be installed at the edge of the window frames, B-pillar, at the location of the window in the middle partitions or their parts.

- When the substrate is ready, they set whole window or frame only. This depends on the unit support structure. Supports should be left, because only on the anchor bolt window will not last long. In addition, it is necessary to fix a window on each side by means of pegs. In order to randomly frame in the middle portion not bent, they must be driven between the wall and the window. Then, using a spirit level to check the levelness of the window you need. If you want to align it, then you need to pick up a suitable substrate. When this is done, it should be with the same level to align the screen in a vertical plane. This will verify the absence of bias. When a window is leveled in both planes can be attached to the anchor bolts.

- If provided pivoted window frame, then a previously prepared hole in the frame by means of the punch, drill holes are made in the wall. For proper installation of windows, you must first fix the lower part of the frame on either side. Then you need to insert the anchor bolts and slightly fix them. After fixing all the anchors need to check the level and if everything is in order, it is possible to tighten the fasteners, but not too much that the frame is not deformed.

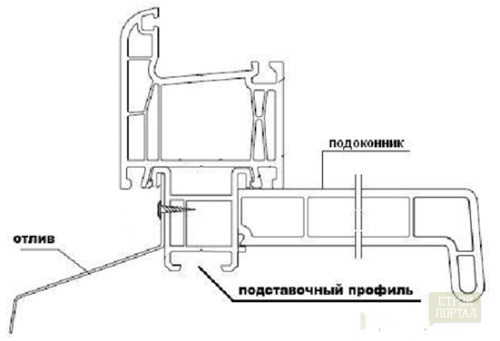

- The situation is different with the installation of the windows on the special fasteners. These fasteners are made of thick metal plate with holes for anchor bolts. They can be fixed in one or two sides of the window unit. Shoulder mount to be bent in the form of a step, the plate should fit snugly against the wall. Then you need to make a hole in the wall anchor bolt. Then attached the lower part of the window first, then the upper and middle part of it. At each stage it is necessary to check the compliance levels. At this stage it is possible to install drainage. Especially there is a special slot for it in the lower edge of the structure in which it is inserted. In addition, it should be further zapenit.

- When anchor bolts in place, you can start collecting a window. First of all, you need to insert the glass windows. At the same time, you first need to fix with the strokes from above and below, and after - to fix the side. So that they snapped until the stop can be slightly tapping on them with the help of a rubber hammer. In the event that there are swam sash in the window, they also need to be put in place. The collected window should be checked how the sash opens. In addition, you need to outow the window installation levels. When all the flaps are checked, you can begin to seal the gaps that are between the window and the wall.

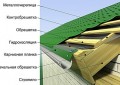

- Polyurethane foam is often used for sealing. But it does not take into account that when this foam is in contact with the external environment and the rays of the Sun, it gradually loses its sealing and sealing properties. In order to avoid this, on both sides of the seam, you need to make reliable protection against moisture. It is necessary from the inside of the window around the perimeter to stick to one edge a hydro-vapor insulation adhesive tape (except for the bottom). At the bottom edge from the inside, under the windows, you need to stick a waterproofing strip with a foil surface. From the outside, to protect foam from moisture, the moisture-resistant membrane self-adhesive strip should be pasted around the perimeter. As a foam, it is best to use the all-season foam, and the robot itself needs to be performed using a special pistol. After filling the gaps, you need to moisten the spray foam and stick protection.

It remains to install the windowsill. It is necessary for starting to trim from the ends so that he can go under the frame and move into a padding profile. On the walls along the edges, it should only come for 50-100 millimeters. The level of the windowsill should be set with the help of pegs. At the same time, the window sill should not be completely direct, but should be a small SCO in the side of the room. After it is based on the level, the space below it must be made or fill with a solution. To the window frame, the windowsill is attached using selflessness from the inside of the frame. This is the overall technology of installing metal-plastic windows.

Features installation of windows in wooden buildings

The installation of plastic windows is strongly affected by the type of construction material used. When installing in wooden houses, it is necessary to take into account both the features of the installation process and the installation time. So, in such buildings, it is not necessary to put plastic windows immediately after construction, it is better to wait one or two years. This time is necessary for shrinkage of wood. During the installation itself, the window to avoid deformation is never placed directly into the window opening. Installation is usually produced in a special wooden box. It is important that there are no defects, damage and rotes on the window block. In addition, the unit should be processed by an antiseptic before installation. After installing the gaps, you need to fill in a jute insulation. These are the features of the installation of metal-plastic windows. The video presented below shows the entire process.

Subsequent expansion nuances

After installing plastic windows, it is recommended 3-4 times a day to 10-15 minutes to air the room. If this is not possible in your case, you can use the micro-taking method or the air valve method. In the first case, the window is used, which allows you to open it not completely. This distance is enough so that in the room there was a normal temperature and humidity, at the same time not enough for the occurrence of draft. The second ventilation method is to use the device, which is a small box, which is installed on the top of the sash. In this case, this part of the window is pre-drilled. The process of ventilation is adjustable using a humidity sensor. The valve opens with high humidity.