Furniture hauling with your own hands Interior items

Even the highest quality upholstery of upholstered furniture and chairs over time loses its gloss, wears. The causes of furniture wear set: frequent cleaning, pets, careless appeal. The springs and foam rubber come into disrepair. But this is not a reason for replacing the sofa or chairs: the materials that have come into disrete can be replaced. Specialist services are a lot, but there is a way to save. Drawing furniture with your own hands - the work that each can perform. We will try to help you with the following guidelines.

Content

What material should be chosen for upholstery

The withdrawal of upholstered furniture will be performed qualitatively if:

- artificial leather should be durable and dense (when choosing, try its edge to break);

- the fabric should consist of natural and artificial fibers and be impregnated with a water-repellent substance (to maintain cleaning with a brush and soap solution);

- the foam rubber must be rigid (denotes "HL", increased rigidity - "EL").

The color and style of the upholstery drawing should be harmoniously combined not only with furniture, but also with other interior items. It is allowed to use a combination of various materials. For upholstery, natural skin, nubuck, flock, tapestry, jacquard, shenill are used.

With a successful choice of material, change the interior for the better, refresh it, the furniture hauling will help: the photos of the original options are presented to familiarize it below.

What tools are necessary for work

Furniture hauling is performed using the next set of tools and fixtures:

- stapler furniture (construction) with brackets 10 - 14 mm long: for one-time work the cheapest tool model is suitable;

- skobudeller;

- porolon (usually used with a thickness of 40 - 60 mm of appropriate density);

- screwdriwer set;

- adjustable key;

- hammer;

- scissors and shoe knife;

- pliers.

Perform a challery seat

- With the help of pliers, remove old brackets and remove the old upholstery. It is still useful: it can be used as a pattern template.

- We inspect the foam rubber: if he smelled and began to crumble - it should be replaced. Old batting that came to dissent also shall be replaced.

- We remove the old porolon and clean the seat from its residues and traces of glue using a shoe knife.

- We inspect the chair: if it is walking, it means that the connections of its parts weakened and require repair. They can be strengthened with gauze and joinery glue (PVA glue). If necessary, use metal corners.

- We put a new foam rubber on the seat of the chair and from the bottom with the marker outline the contour. Recovering about 15 mm at the edges, we cut a new substrate and cut it out.

- Scissors cut off the top of the top (rounded the angle). We apply a few drops of PVA glue and put the foam rubber, slightly pressing it. You need to wait a few hours while the glue will dry. Such a measure is needed so that the soft material does not displaced during the upholstery stretch.

- Old upholstery put on a new tissue and outline the contour with a marker. The allowances are not needed if the old material has been strengthened with the "oddon".

- Scissors cut out the contour of the pattern and lay on the seat the face up.

- For convenience, we turn the chair on the table: it will be more convenient for it.

- We correct the upholstery fabric and begin to fix it with a stapler, converting the edges of the material. Similarly, change the upholstery on the back.

IMPORTANT: Fixing the upholstery is needed "Cross-crossing". Initially, the fabric is at one point, and then pulling on the other edge of the seat on the back side. After that, we also act, shutting up 90 degrees around the circumference, and then - throughout the edge. It should not be tightened too much to the fabric to avoid deformation of the pattern of the face of the material.

Leather sofa dragging

The leather furniture leakage is performed after repairing a wooden frame. In the course of operation of the sofa, it is loosened, glue dries, and the compounds require repair. This is done after dismantling the old upholstery and foam rubber. After that, proceed to the restoration of upholstery.

The quality of repair depends largely on the proper skin selection. It should be borne in mind that after stripping the skin is separated. Each layer is characterized as follows.

- The first, the upper layer is distinguished by elasticity and high strength. This is the thick natural material suitable for the upholstery of the part of the furniture, which is exposed to the greatest operational loads.

- The second layer refers to the second category in quality. Such skin is mild, but thin and less elastic and therefore used to create assemblies and folds (soft forms).

- The third layer is hard, thin, with a violated texture of natural material. Such leather is separated by rear parts of the back and the sides of the windowsides.

- The fourth layer is thick, heavy and often with defects. It is suitable for the upholstery of the back side of the sofa, under the condition of its installation close to the wall.

High-quality leather has the following features:

- after stretching is restored, keeping the shape and without forming folds;

- it breathes: if you make a hand, the material quickly heats up, due to the ability to turn moisture into heat;

- the seams after stretching should quickly return to its original state, and the decorative line should be neat.

A sewing machine with a mode that allows you to handle a dense fabric is added to the setting of the tools indicated above. Phased, the entire process of the sofa is as follows.

- The sofa disassembles: removed armrests, back and seats.

- Old brackets are extracted by the passage, after which the bottomable tissue is removed.

- From the list of the above-mentioned materials, the suitable color and composition is selected. For the medium sofa size, up to 10 m canvas with a width of 1.5 m.

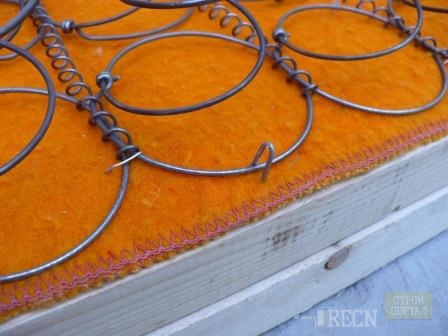

- If necessary, change the spring block or individual springs. The sign of their wear is irreparable deformation, "Sed". New fasteners to frame brackets made from steel wire with a diameter of 3 mm.

- A dense palace is stacked over the spring block: it is necessary so that the metal does not break through the soft foam or batting. On top of the palace, it is recommended to lay tight felt and strengthen with thick threads or twine.

- If the plywood under the spring block is broken - on top or instead of it, a sheet of new plywood is attached.

- Check the corner all compounds whose docking is performed at an angle of 90 degrees. Correct and strengthen all the angles.

- Putting: if it came into disrepair - it should be replaced. To do this, use dense foam rubber, felt, holofiber, syntheps. Using packing, you can change the style of furniture by adding or reducing the amount of material in the head of the head and on the armrests.

- We cut a new upholstery and, if necessary, we grasp the seams on the sewing machine. Allowed to combine various materials.

- When fixing the upholstery, it is necessary to ensure that folds and savings are not formed. For fastening the material to a wooden frame, it is not only a stapler with brackets, but also nails with wide hats.

- The resulting upholstery memory can be corrected by stretching or attenuating some sections.

- After fixing the upholstery, the sofa assembly is made.

Taking a soft chair

The fundamental differences in the technology of work on the technique, which is indicated above, there is no, but some nuances need to be considered.

- Photos should be taken photos of the most important details of the old upholstery (places of compounds of different parts). This will facilitate the manufacture of patterns and further work.

- It is required to unscrew the legs, remove the wooden decorative lining from the handrail.

- Remove the old upholstery you need to carefully plowing the seams. After that, all the details smoothed out the iron to make it easier to cut off the upholstery from the new material. It is recommended to numbered them or sign a marker.

- Paving from the foam rubber and other materials are manufactured by using the pattern and measurement results by the port of the portor.

- When buying upholstery fabric, it should be found out if the material sits down "after washing. If the trend towards the shrinkage is - you need to wash the fabric and smooth before cutting.

- All parts of the patterns are connected by the corresponding seam, after which the resulting cover is put on the chair. The material is attached in some places after uniform careful stretch. If the windows are manifested - adjustment is performed. Sample can be performed several.

- After the final stitching, the case is fixed to the framework of the chairs with brackets and nails.

- The legs, wooden decorative linings and armrests are screwed into place.

After such a major repairs of furniture and drying, she will serve many more years.

In conclusion - educational material on how the furniture is performed (video).