Waterproof waterproofing: characteristics, properties, laying technology Insulation

At a certain stage of construction, the house should necessarily take the necessary measures to protect the vulnerable elements of the design from atmospheric moisture and groundwater. It will not only make the house comfortable, but also will prolong its life, will reduce the cost of heating the premises.

One of the effective ways to prevent problems are inland waterproofing. Technology provides styling several layers of roll material. Read more about this below.

Content

- Basic information about rolled waterproofing

- Marking of waterproofing materials

- It should be aware of the inlet waterproofing

- General information about inlet waterproofing

- Properties of polymer waterproofing

- The characteristic of bitumen-containing waterproofing

- Device of inlet waterproofing

- Advantages and disadvantages of various types of rolled waterproofing

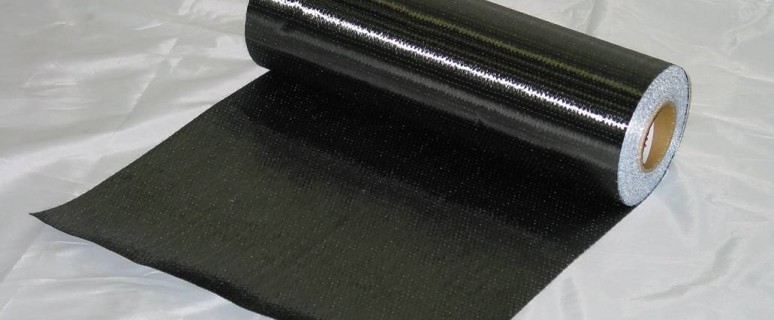

Basic information about rolled waterproofing

The following elements of the construction of buildings and structures should be protected by waterproofing:

- foundations;

- roofing;

- indoor rooms with high humidity (cellar, basements);

- surface of hydraulic structures.

Waterproofing materials are divided into:

- coating;

- piece (or rolled).

The latter can be applied to the surface by the method of burning, with the help of special fasteners (mechanically) or planted for glue. How to distinguish them from each other? All information about the material is laid in its marking.

Marking of waterproofing materials

In the store without the help of the manager, you can easily distinguish materials on alphabetic designations in marking.

- The letter "K" denotes that this material is both roofing and waterproofing. A protective layer of stone crumb is applied to the surface of the rolls. The length of the rolls is 10 m. Roll inlet waterproofing TechnoNIKOL is estimated depending on its thickness (usually within 3.5 - 4.0 mm), the length, material of the base and the composition of the bitumen.

- The letter "P" is present in the labeling of waterproofing materials for the base or floor. They have no stone crumbs, both sides are covered with bitumen. Rolls of 15 m long (sometimes less) are wound from sheets with a thickness of 2.5 mm. In addition to isolation of basements, pairs, cellars, etc. They are used for flooring on the roof before laying the upper layer.

It should be aware of the inlet waterproofing

Waterproofing materials of this type are self-adhesive and such for the installation of which the adhesive is required. The latter are used more often, bituminous mastic is required for their stickers.

The most common type of inlet waterproofing is ruberoid. But recently it is used less often. The reason is a continuing cardboard basis, which comes to the change of more advanced materials.

According to the method of orientation, waterproofing is a roller cooler:

- horizontal: it is placed on top of the erected foundation in order to prevent the possibility of spreading moisture towards the walls of the soil on the capillaries;

- vertical: bituminous rolls stick to the foundation immediately after the end of its construction, but before the inverse swelling of the soil is performed.

The task of vertical waterproofing is to overlap the path of groundwater to the base design and other elements of the building. On top of the roll material, the membrane is mounted, also intended for hydraulic protection.

A separate group is a rolled waterproofing, for the installation of which mechanical fasteners are required. This includes a hydrobarier and membrane. These polymeric materials are laid under the roofing material of the pitched roof and over the external walls of the foundation.

General information about inlet waterproofing

Equal waterproofing foundation in individual construction is used more often than other methods. The reason is that for its installation does not require the use of complex equipment and you do not need to have special skills.

The advantages of inlet waterproofing are as follows:

- relatively low cost;

- the ability to perform quick installation on the foundation and roof;

- the pasting is performed using the primary means.

Some features of this method should be taken into account.

- When using open fire, a certain danger occurs.

- Problems of processing of hard-to-reach places (pipes through the walls and roofs, sharp internal angles, etc.).

- The inability to use near plastic pipes, cables and other melting materials communications.

- The need for preliminary surface preparation: Alignment is performed, primer. Sharp edges of the protruding reinforcement should not be.

Properties of polymer waterproofing

Such waterproofing (no self-adhesive film and vulcanized rubber membranes are made using the most modern technologies and therefore is the most expensive. Released by WVID sheets or rolls. Among her qualities should be allocated as follows:

- high mechanical strength and long service life;

- small thickness;

- lack of shrinkage in compression;

- low vapor permeability (requires a ventilation gap device);

- resistance to vibration loads.

The characteristic of bitumen-containing waterproofing

Due to the relatively low cost, bitumen isolation is the most common. Among modern materials, this refers hydroizol, the basis of which - fiberglass impregnated with bitumen. The additive of the plasticizer makes it flexible and resistant to cracking. Hydroizol is durable, since it is not subject to rotting.

To protect against moisture, two- and unilateral hydroelectors are produced. Two-sided distinguished by the presence of a protective polymer film, which melts with severe heating. It is used for a multi-layer insulation device of buildings. One-sided hydroizol has a protective coating of mineral crumbs.

Device of inlet waterproofing

Phased the process of laying rolled waterproofing using mastic can be described as follows.

- The surface on which rolled waterproofing will be placed, it is necessary to align, clean from dust and dry well.

- All sharp protruding parts of the reinforcement should be cut down so that they do not damage the rolled material. The depressions are sealed with cement mortar.

- Rolled waterproofing rolled pre-near the foundation so that it is leveled. In the absence of a free area, retroactive rolls of rolls.

- For stickers, a bitumen brand is selected (bitumen-polymer or rubber mastic) in accordance with the ambient air temperature. The mastic (bituminous) was heated until its temperature exceeds 25 ° C of the ambient temperature. This is done with the help of gas or gasoline burner and metal container.

- The first layer of mastic should be applied with a layer of about 2 mm, which is performed using a brush or roller.

- The rolled material is glued to the wall from the bottom-up so that the top cloth for several centimeters overlap the edge of the lower canvas. If possible, the waterproofing is unwinding directly from the roll, sticking onto the wall on the helix.

- The waterproofing material to the wall is tightly pressed, which moves the air (as they do when wallpaper sticker).

- On top of the first layer of waterproofing, mastic is applied, after which the second layer is glued in the same order. The direction of laying is preserved. Total layers can be two or three.

Recommended in the process of using the following tips:

- for waterproofing horizontal surfaces with a length of over 10m, it is convenient to use additional devices;

- the inlet waterproofing must be protected from external mechanical effects (landslides, trees roots, etc.) by stone and reinforced concrete structures;

- on the hot bitumen imposed on top of the last roller material, coarse quartz sand is applied;

- the nesting of the roll material during installation should be no less than 10 cm;

- the edges and edges of waterproofing should be carefully coated with bitumen;

- when the roof is waterproofing, the rolled material is rolled over the surface after heating the base and the inner side of the roll of the gas burner. This is shown in the video.

Advantages and disadvantages of various types of rolled waterproofing

- Bituminous mastic applied to stickers of waterproofing rolls, cheaper than other types of mastic.

- Bituminous mastic requires the use of open fire, which makes the performance of the work dangerous.

- In the closed room (cellars, garages, in the basements), the installation of waterproofing with a preheated bitumen is not made due to the danger and inconvenience of the burner.

- Rubber-bitumen mastic is more suitable for waterproofing works indoors. It has a high degree of elasticity.

- For waterproofing of indoor surfaces, it is recommended to use membrane materials: the installation is performed by the "cold" method, the seamless coating is formed.

- The composition of membrane materials allows them to be used in rooms with high humidity.

- Self-adhesive rolled materials are laid after processing the base primer - a special bitume-based composition.

You can get more information about the rules for mounting self-adhesive waterproofing using the following video.