Column foundation under the house with your own hands Construction

The durability of any home depends on how reliable is the foundation on which it is worth. Therefore, to the choice of the method of installing the foundation should be approached with special care. A columnar foundation under the house is the most simple and at the same time an economical option. Next, we will tell you more about technology and methods of its construction.

Content

Characteristics of the column base

It consists of several columns. Each of them is located in places where the highest load is accounted for, i.e. In the corners, in the zones of the intersection of walls, under the crowns of pipes, carriages, etc. This kind of foundation is most suitable for building a small weight building without basement. For example, it is used when erecting a wooden house, in the design of which pillars are provided. For a wooden house, such a foundation is usually made of stone or wood.

The column basis is valued primarily for its efficiency. There are several types of its varieties depending on the construction technique.

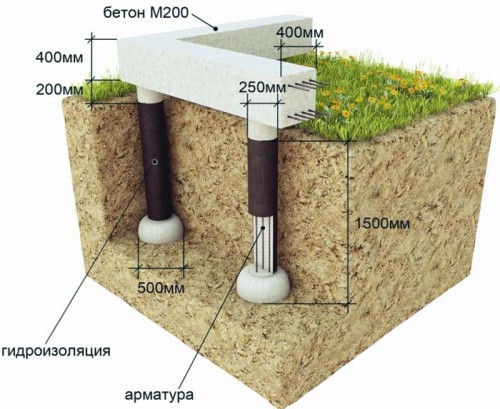

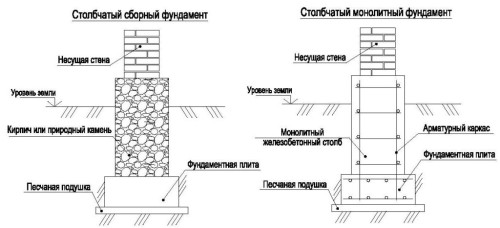

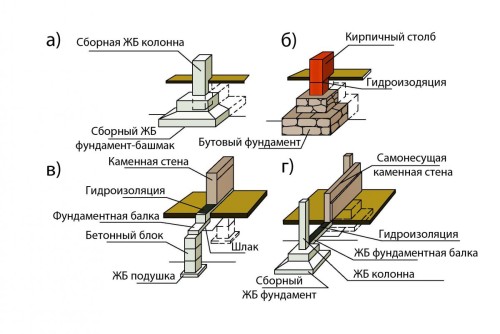

- The monolithic column foundation is the most popular option. It is a high-strength sole, made of reinforcing rods and concrete.

- Prefab column basis. It can be rapid enough enough. It consists of stone, bricks and reinforced concrete plates. Its "weaknesses" can be attributed to the fact that its seams are unreliable.

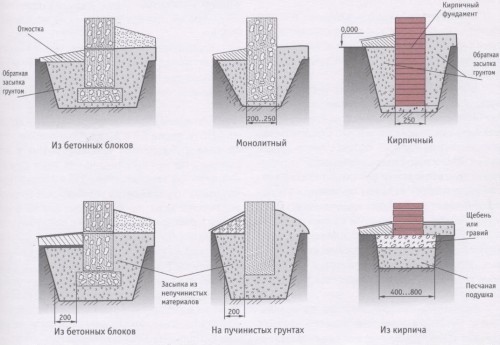

Depending on the method and depth of the pillars of pillars in the ground distinguishes a blurred and small-breeded column basis. One or another is chosen as a rule, depending on the type of soil, as well as on the level of groundwater. Thus, the plated form of the basis is mainly used in a wet clay soil and bury it in such a way that the lower end of the poles is half a meter below the level of lability of the Earth. As for the small-breeding option of the foundation, it is mainly used on sand or stony soils, and the posts are buried in the ground just 0.5-0.7 meters. No matter how much differences they have, any columnar foundation under the brick house is built by a similar scheme. Next, we consider in more detail the characteristics and methodology for the construction of each of the options.

Column basis with painter

For a uniform distribution of the load on the base in the design of the column-in-inclined bases, paintworks are used in the form of the connected beams or plates. For its manufacture, concrete or reinforced concrete are usually used, less often - wood or metal. It is usually located at the top of the foundation. Scarlet can be low and high. The first species is located underground, and the second is higher than the level of the soil. The use of woodwork allows you to make the design more durable, reliable and durable.

Bulk Foundation

We are necessary when building structures from wood, in which it is not planned to equip the ground floor or a basement (for example, it can be a bath or utility room). If you compare the column basis of this type with other types of foundation, then its cost is much lower, which is often decisive when choosing. If with the construction of this type of basis, concrete blocks are used, they perform the role of leading supports. Moreover, their number depends on the size of the future building. When using such a basis, the basis of sand is usually made as the base of the bath. At the same time, the blocks are stacked in several layers until the desired height is obtained, the lowest of which are bored in the ground. For brick buildings, such a foundation is no longer suitable.

Pobble foundation from pipes

The design of this foundation uses a formwork in the form of pipes from steel or asbestos. Moreover, it is a stationary element. Pipe material is usually chosen depending on the nature of the terrain and construction. Thus, during the construction of a small surface of a small wooden house, asbestos pipes are usually used, in other cases it is desirable to give preference to steel.

Previously before installing pipes in the soil, the openings of the desired size are performed. In addition to the pipes, asbestos frame is inserted. Pipes after installation are first filled with a solution for only a third. When the hydraulic cannon is formed, the solution is gradually poured up to zero. Moreover, periodically tubes are vibropress so that there are no air bubbles.

The next step is the form seal. This is done with the help of soil. As for insulation, it is done similarly as for other types of columnar bases. The same applies to waterproofing and shockting. It should be said that over time moisture can accumulate in the pipes. Therefore, special attention is paid to the waterproofing. In addition, so that the pipes are smooth, they cannot be left without load. Otherwise, they gradually pushed out soil, which is unacceptable for any basis.

Column foundation from a wooden bar

When making a foundation from wood, it is recommended to choose an oak or arrays of coniferous rocks. They are the most persistent, especially after processing with antiseptics, which will allow pile of daunting decades. For piles, the lower part of the log with a diameter of at least 200 mm is suitable. Each such support will go to Earth at least 0.5 m, but not more than 1.6 m.

The inexpensive wooden column base has several advantages, which in some cases become decisive. One of the "strengths" is a simple technology and cost. For the house, when using such a foundation, additional protection is created. In addition, thanks to its design, this basis is bent the deformation processes. As for the shortcomings, then, in the first place, it is necessary to note the short period of such a foundation. Nevertheless, many just ignore it in favor of the inexpensive price of a wooden foundation and the speed of its installation. After the construction of the base, you can start building the house itself.

Bolt-belt foundation

This type of base is erected by standard technology:

- First of all, you need to prepare a plot for construction. For this purpose, an excess soil is removed from the surface so that it turns out to be smooth.

- Then you need to make the markup of the site according to the drawing. For this purpose, the construction thread will help, which will need to be pulled in the form of two parallel lines. The distance between them should be equal to the required thickness of the foundation. The threads should intersect strictly at right angles. The same applies to the angles of the future design. It will be necessary to designate the places where the walls will be involved and intersect the walls, as well as other design sites that have a large load.

- Next, according to the markup made, it is necessary to remove 35-40 cm of soil in those places where the ribbon part of the structure will be. It is important that it remains enough space for formwork.

- Now take a manual drill and according to the drawing, make well for pillars. If the supports are plugged by more than 1 m, then the walls of the well will need to be fixed from squeezing using backups from the boards.

- In order to finish with earthworks, it remains to fall asleep on the bottom of the trench layer of sand and double-check the location of the wells so that the foundation turns out to be smooth.

- After earthwork work, the column arrangement is proceeded. The pipe for the pillar of the desired diameter is formed from the rubberoid, which twists in two layers. Next, the connections are sicked with scotch. The resulting design is inserted until it stops into the well.

- Before pouring a concrete, the posts must be strengthened by means of a reinforcement frame, which is inserted into the well. From the well, the rods must perform at least 150-250 mm.

- Now you can pour with concrete poles. And the first thing to be done is to form a sole of support. To do this, pour into a pipe of 20 cm of liquid concrete into the pipe, and then lift it a bit from the frontier to the concrete to grow slightly around.

- When the sole is ready, you can pour the remaining space of the pipe. As the deep vibrator is periodically used as fills. This is done in order to inside the solution there are no air bubbles.

- When the pillars are filled, they are left until the concrete hardens. During this time, you can make another job to arrange the foundation. In particular, form the reinforcement of the basis in the form of a welded frame from reinforcement and wire. Moreover, the rods are placed along, and the wire across the basement tape, forming the so-called horizontal jumpers. The welded frame is screwed to the rods sticking out of the columns.

- When the frame will be completed with the frame, you can proceed to mount formwork. For this purpose, use boards or paneur thickness 40 and 100 mm width.

- When the formwork is shot down, you need to do waterproofing. So, the material for waterproofing is littered inside. It is desirable to use modern membranes or polyethylene films as it.

- Next, begin to fill the foundation concrete. To make such a large space, it is easier to fill, you can use a special technique, namely, the mixer car. According to the same scheme, as for pillars, you need to get rid of bubbles inside the concrete, which also uses the vibrator.

- Then you need to wait until the concrete gains sufficient strength. This is usually required for about a month. Only after this period you can shoot a formwork and make waterproofing for the basis. After which the remaining trenches should be filled with soil.

Basis of concrete blocks

The use of such a foundation is not uncommon. A crushed stone is usually used as a base, and the sand pillow is embrying on top of it, which, in turn, block blocks. The blocks themselves are binding to each other with a cement solution. It should be noted that such a basis is not suitable for horizontal moving soils, as well as for the construction of heavy structures.

Calculation of foundation

For the correct calculation, first of all, it is necessary to measure the depth to which the foundation and reinforcement will be laid. Not knowing this, it is impossible to carry out calculations. In addition, you need to find out the characteristics of the site where the building will be built. So, for calculation, you need to learn the depth of groundwater and how this level changes throughout the year. No less important information about the average temperature in the winter and the level of soil freezing. The data on the properties of the soil will also be required.

It is desirable to approximately estimate the total weight of the house and its future interior. It will be necessary to determine the total weight of the very basis and seasonal loads. Under seasonal loads, in particular, they understand the snow cover and wind. In order to find out how much posts are required for the foundation and their size, you must first determine if their carrying capacity on the soil type of your site. In addition, the maximum load on one pillar is calculated. Under the load understand the amount of weight and column, and the load from the house.

When the carrying capacity of the soil in the site is known, the basis with a permissible load should be tested. To do this, find a product of the volume of one post and the strength of the soil. It will not be superfluous to check the correctness of the calculations for reliability several times.