How to make a frame for greenhouses from the profile pipe with their own hands Useful advice

In the zones of risky agriculture, the effectiveness of agronomic effort depends only on the greenhouses. Qualitatively assembled and thoughtful buildings will allow to collect an early harvest in April. If you try and spend a heating system, then it will be possible to collect the harvest of greenery, vegetables and berries.

Content

Types of greenhouses

The modern industry produces all the necessary materials that make it possible to build a carcass with their own hands. Profile pipes or PVC pipes have become a low-budget building material. For the assembly of the design, special professional skills and knowledge are not needed, the desire and following the advice.

Advantages of this building:

- Easy assembly.

- Simple dismantling.

- Apply a simple toolkit.

- Lack of additional maintenance costs.

- Resistance to rotting and fungal damage.

- Stability to deformation caused by increased temperature.

Build greenhouses for large summer cottages is offered from several popular materials: frameworks made of steel, profile and aluminum pipes. The solution to the selection of the material depends on the capabilities of the budget, but in any case, the carcasses of greenhouses from the profile will be a cost-effective option. The profile provides high operational quality buildings and cost cheaper than metal pipes.

The experience of the owners allowed to allocate the most successful for the yield of sowing the shape of the erected greenhouses:

- Arched shape. Suitable for growing low plants. The roof is self-cleaning from snow nansions and garbage.

- Tunnel shape. It has standard dimensions: height 5 m, width 10 m. Ideal for growing tall plants (curly or vertically growing). It has increased resistance to airflow absorbers.

- Duscaty form. It makes it possible to build high designs. Used to grow greens on supports, curly and reprehensive plants. It makes it possible to dispose of the area of \u200b\u200bthe site rationally when erecting several greenhouses. Vertical walls are more tightly adjacent to each other, not leaving unused land plots.

- Pyramidal form. Due to the compact design and narrow dimensions, the construction takes at a minimum of space. Used under the cultivation of material for seedlings.

Proper definition of a place for the construction of the greenhouse

The construction of greenhouse requires the correct location to the parties of the world. It is necessary to create the conditions of the greatest sunlight in the day to ensure comfortable conditions for cultivation.

The greenhouses do not erect close to tall trees, giving shadow. Increased air temperature inside the design compensate for the device of the ventilation system. In advance, provide free approach and delivery of manual vehicles or car for harvesting.

For heated winter greenhouses, it is best to choose a place next to the residential house, it will reduce the cost of heating. The close arrangement gives an advantage in using one aggregate for heating and supplying the coolant to home and greenhouses.

Tip №1: Constructions with an elongated form must be located from the east to the west.

Council №2.: On the two-tie roofs, the checking of the ventilation is put on the southern slope.

The initial stage of construction

On the frame frame frames, they take pipes with a profile diameter of 40 x 20 mm, they are powerful and well retain stability during wind gusts, do not deform under the influence of high temperature. For a bunch of honey, the frames are ideally suited for a section of a section 20 x 20 mm.

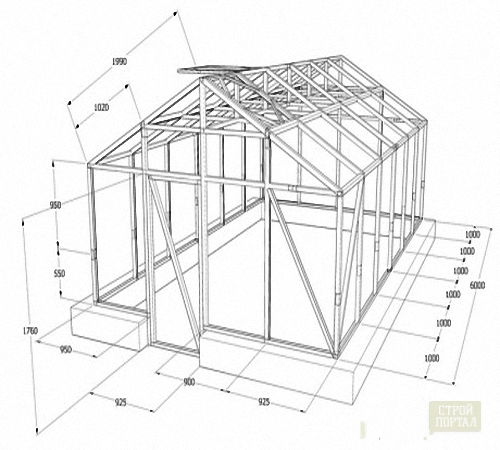

Work begins with the implementation of the future design scheme. The optimal dimensions of the greenhouse are displayed in the drawing. The plan allows you to visually present the carcass of the greenhouse and choose its dimensions in such a way as to reduce metal losses when cutting to a minimum.

The semicircular frame has a large useful area than two-tie, but for its construction you need an expensive machine - pipe bender. Manual flexible tube filled with sand, more complex and does not give the desired arc geometry. The most optimal option is a divertile building. Its square will be enough to place plants of different sizes, it provides good entry of light, makes it possible to install additional elements: windows, opening frames, doors.

The carcasses for greenhouses from the profile are calculated under the length of 6.05 m, since it is precisely such a length of the segments are implemented from the warehouses and are considered standard.

Take a height of 1.7 m, the profile will need 3.4 m. From the total length of the segment, a non-refined piece of 2.65 m long remains. Taking into account the angle of inclination of the roofing of the roof, usually angle 30 0 We get a width of 2.24 m.

The resulting width by reducing 24 cm, then it will be possible to cover the greenhouse with a standard sheet of polycarbonate, and also leave lateral skes for water drain.

The selected diagram of the two-tie design frames will allow you to do without expensive tools.

Next, choose a design for the base of the greenhouse. Embodiments can be different. The foundation is built from any suitable material, ranging from the railway sleeve, ending with the head of the screw pile. Consider the most popular and suitable option - concrete, small foundation, with a depth of 1 "bayonet" shovels:

- Before the fill, the surface of the construction site is smoothed, drove to the pit.

- Then an anchor for fastening profile pipes is laid around the perimeter.

- A solution is prepared from a mixture of cement, sand and small pebbles, as in conventional construction.

- The mixture is poured into the pit and remains until the concrete is set.

Montage Karcasa

When the concrete mixture was grabbed, we collect a carcass of greenhouses from pipes. To the mortgage parts weld the profile with the diameter of the cross section of 40x20 mm. It will be a solid foundation for fasteners of basic and auxiliary greenhouses.

So that there is no distortion, the assembly of the frames is produced on a smooth and, preferably dense area. On the existing, on the plot of a suitable area, make the outline of the outline of the future frame, measure, and then proceed to cutting in size of the main drawing.

Do not rush to immediately cut the whole profile cut, just perform an incision in the place of bending. Then carefully and gently bend the pipe at the place of the door to obtain a frame of the required configuration.

Cut cuts determine immediately, consider that when flexing the sections should be docked with accuracy. Now, proceed to coach coil on the collected workpiece.

The end frame is an important carrier part of the whole design, the door with the window will be installed in it. Set them better on the frame lying on the site. The mass of the door with the window is small, so it will not affect the subsequent installation. The door frame is welded from the profile tube with a cross section of 40x20 mm, the fortage is made from the profile by cross section 20x20 mm.

Taking into account the width of polycarbonate -2 m, the arches step is selected. Its length is selected with the calculation of the joints fall on the profile tube. The stiffness of the frame tubes 40x20 allows you to take a step in 1 m. The frame frame frame is mounted with a gap of 1 meter, bonded between themselves between the sections of the square section of 20x20. For this, the segments are welded with the main profile. Such a compound allows to cover the greenhouse with a smooth layer of polycarbonate, without irregularities and wrinkles.

Installing the elements of the vertical frame starts with the end frame with the door. For accurate coincidence with a vertical plane, it is fixed by separating the corners welded to the horizontal tube of the foundation.

The horizontal bunch of profile tubes is set with an indent of 10 cm from the location of the frames, which will allow you to qualitatively attach a sheet of polycarbonate in length and width.

Proper fastening of greenhouse shelter

After installing all the operations on the assembly, welding and installation of the frame, making sure of its strength, checking the location in planes and verticals in terms of the level, proceed to the installation of the coating.

First prepare tools and fasteners. Self-tapping screws are suitable for fastening 3.2x25 mm with pressshima, a specialized polycarbonate fastener kit, consisting of self-pressing + thermoshaba.

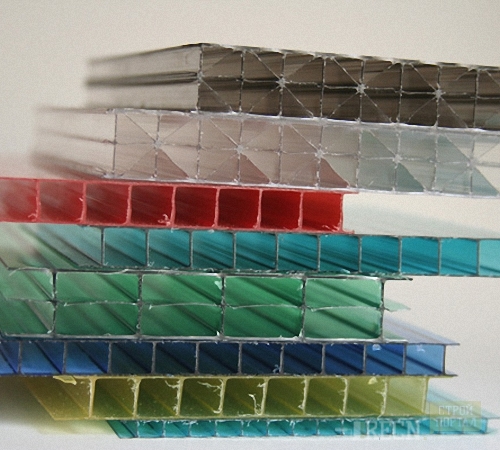

Standard polycarbonate width - 2 meters. Mask is attached, the front side is out. Usually, the reverse side of the marking to the product is indicated.

The shear end is protected by professional sealant, for example, silicone, or a plastic profile is used. The polycarbonate sheet for the roof cover should be 10 cm longer skate profiles, then it turns out the standard, sufficient foot.

The joint of the roofing skate from profile pipes is covered at the request of the profiles of metal tiles, PVC and others. Fixing is performed by self-drawing to longitudinal connections.

Polycarbonate sheet is mounted on the door and forward frame in analogous to the process of coating frames. The only one is selected the size of the coating strictly in size to ensure normal opening and closing doors. If you leave the reserve, it will not be a dense hermetic closure of the greenhouse.