Production of concrete pillars for fence with their own hands Construction

Often, in the improvement of or creating a country house, the country's cottage plot is thinking about what material to make a fence. What is better to make a fence: a brick, wooden or the best chain mesh is best suited. But the most important thing is that almost every owner of his own home faces - the choice of the foundation for the future fence.

Content

The options for installing fences that will serve as a support for the future fence of several: it can be metal racks, brick and concrete.

Consider more, how to make self-concrete poles for the fence. Some daches will be surprised, why make this work yourself, if you can buy ready-made wooden columns. In fact, it will not always be convenient to hire a car and movers, which will unload heavy reinforced concrete structures, and then also pay for their installation. And it happens that there are no concrete pillars of the desired size and thickness. That is why make a fence for the fence will independently be the right decision.

Benefits and disadvantages of concrete supports

Before starting work, we find out the positive and negative sides of the concrete pillars.

Advantages:

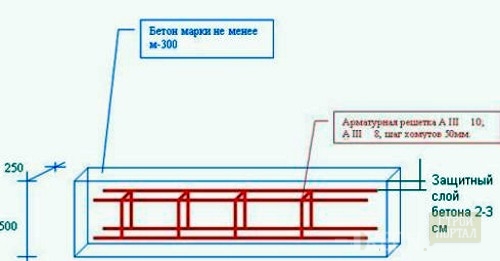

- Durability. Compared to wooden supports, concrete will serve dozens of years. But the quality of cement affects the strength of the structure. Specialists recommend working with the cement M-300, M-400 and M-500 cement.

- The pillars can be separated by such materials: plaster, plastic panels, decorative stone or paint in any color.

- Easy installation. Expensive building materials and special tools will not need. Everything can be done yourself.

- Concrete pillars under the fence will serve for many years in a row.

There is only one non-essential deficiency in concrete supports: for their installation, it is necessary to prepare the basis for the foundation for the fence. Without the base over time, the whole design can be deformed and even fall.

Necessary materials

To install a half-one-step fence, you need to prepare concrete supports with a height of about 1 meter of 80 centimeters.

In order to make independently concrete fences for the fence, you will need such tools:

- screws;

- hammer;

- sheet of plywood or wooden boards;

- metal reinforced rod;

- polyethylene;

- welding machine.

This will look like ready-made concrete supports made by their own hands, subject to the construction of a figured formwork.

How to make a formwork

The secret of smooth and durable pillars in good formwork. Therefore, it is not necessary to save on it, the better it will be done, the greater the supports will be done.

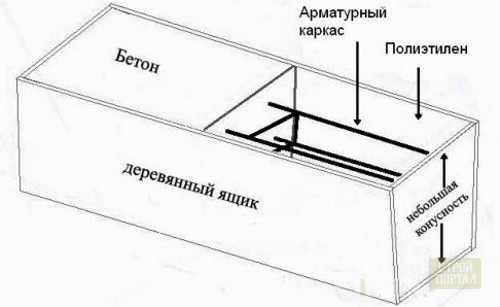

One of the simple formwork options is the usual design in the form of a box. If there is no plywood, formwork can be done from ordinary boards. The ends and three sides of the future shape bonded among themselves, and one side is left open - it will be the place where it is necessary to pour a concrete mix. So that the cement fluid does not flow out from the formwork slots, the boards or paneur are carefully customized and paired inside the polyethylene. It will be better if the walls of the formwork are additionally seen plastic so as not only to prevent cement flow, but also protect the walls from swelling and deforming. In addition, the frozen concrete will be much better to lag behind smooth walls, and the formwork will be easier to disassemble. Therefore, the shape is collected on screws, as they can be easily removed in order not to damage the boards or phane.

What a formwork looks like, you can see on this drawing:

Support strength

In order for the design of the fence is durable, not only a high-quality cement solution is necessary for the manufacture of concrete pillars, where the ratio of sand with cement is the proportion of two to one or three to one, as well as high-quality metal fittings. Without it, a concrete table will not ensure the stability of the entire design of the fence.

Metal rod laying scheme can be seen on this photo:

It is necessary to have a welding machine in the presence to assemble a metal frame yourself. For its manufacture, you need to cook the grille of four rods located along (diameter 12-16 mm) and short rods located Popict (diameter 8-10 mm). The step of transverse segments should be from five to fifteen centimeters.

When installing a frame from the reinforcement in the formwork, it is necessary to leave a small gap (about 2 cm) so that the concrete layer filled the space and thereby protects the metal from corrosion.

Preparation of concrete mix

After collecting the formwork and installation of the metal frame, the next stage is the preparation of a concrete solution. To fill the capacitance of formwork, you need a crushed stone. It should not be large, the optimal size of rubble - 5-10 millimeters.

In order to prepare a concrete solution, it is necessary to take one part of the powder, two parts of the sand and a lot of water. With the help of concrete mixer or manually prepare a solution. After the concrete mix is \u200b\u200bready, you can proceed to the fill of it into the formwork. It is necessary to carefully pour the mixture so that in the future concrete post so-called "empty shells", which significantly reduce strength. Therefore, after a concrete solution is flooded with a formwork, it needs to create a vibration so that the mixture seals slightly and displaced the air. To perform vibration, you can use the perforator, to install a metal bar with welded at the end of the vestment. It is necessary to presumpt the perforator to different sections of the formwork so that the concrete mixture soak. If there is no perforator, then the mixture can be swapped with a small rod in several places.

After the fill of concrete supports for the fence is complete, you need to take a board or another item having a flat surface and spend it on top of concrete. Now the concrete pillar leaves seven days before complete drying.

Second version of the manufacture of columns

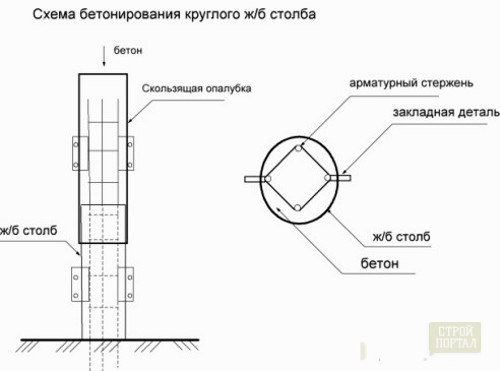

For those who wish the fence with concrete pillars consisted of a support of another form, we can make concrete bases of a round form. To do this, pre-formwork from the tree do not need. It is necessary to take the metal pipe of the desired diameter, which will serve as a form. Pulley is performed by concrete solution as follows:

- Metal pipes are laid in the ground.

- Right into the pipe, the concrete is poured on the spot.

- Metal frame is installed.

Such a technology saves time, as the part of the pillar is cast at once, which is in the ground, and the one that will serve as a support for the fence of concrete pillars.

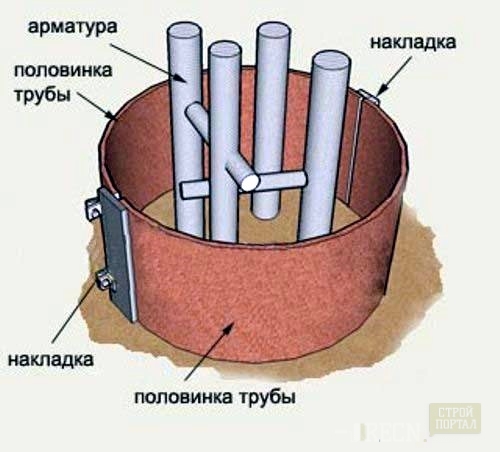

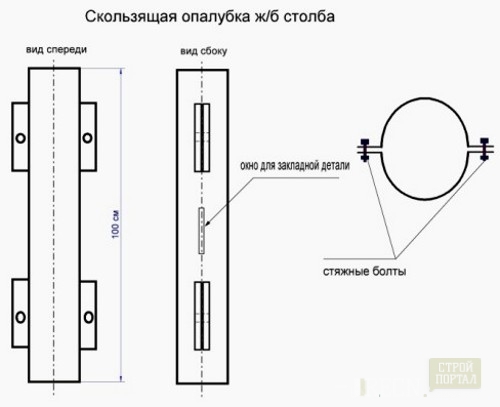

How to do it, you can look at this image:

After complete solidification of the concrete, with the help of the method of the "sliding formwork" on the pipe make a longitudinal section, weld "Kosinki", with bolt holes. To both parts of the pipe well revealed, the inner part is lubricated with machine oil. In order to avoid the deformation of the design, vertically determines with the help level.

Such a technology for the manufacture of concrete pillars allows you to do both smooth and decorative pillars with different embossing.

After the supports are made and installed, the caps are installed on the posts on the poles for the fence.

New comments

Add a comment

To send a comment you need authorize.

thank you for the information, useful