Mounting Metal Block Haus Construction

Wooden logbs were always relevant and still remain those. But, the construction of a house of a whole log assumes not only significant costs at the procurement phase of natural wood for project implementation. In addition to complying with the shrinkage of such a house, it obliges to proper care and maintenance during operation, which is also quite expensive. It is for these reasons that the material that has recently emerged in the market is a metal block house, stylized under the wood, immediately began to enjoy high demand. Such popularity is due not only to the fact that an externally cottage looks like a real log house. Metal block house is a winning solution from the point of view of practicality. What exactly is distinguished by this material, in what sizes it is supplied to the market, in which its advantages and what rules when installing must be observed - all this you will learn from this article.

Content

Features of the device metal block house

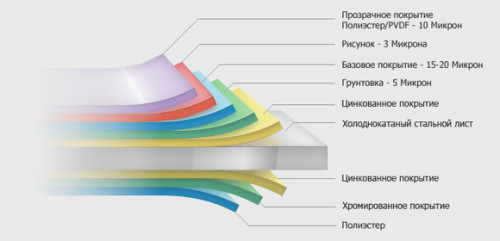

Metal block house under log is made according to unique technology. It is a multilayer material that consists of:

- Basics of galvanized cold steel.

- External finishes - layers of primer, basic, patterned and transparent protective polymer coating with a thickness of 3 to 20 microns.

- Interior decoration consisting of 2 layers - chromium + polyester.

Important! The outer form of atolar or two-ventricular design is created on special profile focus machines. The drawing itself, simulating the texture of one or another breed, is applied using the photo-offset technology. What looks like such a sequence of actions of masters manufacturers Metal block house, you can view in the photo.

Material is manufactured in this way:

Benefits of material

Each material has its advantages, based on which any builder prefers a more suitable option. The decoration of houses with a metal block house also has its advantages, the list of which is very extensive.

The most important is:

- the optimal service life is about 50 years;

- resistance at any temperature differences in a wide range of indicators - from -50 to + 80c;

- preservation of all initial technical characteristics in the adverse effects of ultraviolet, chemicals, natural precipitation;

- high fire safety level;

- minimal thermal expansion, which eliminates deformation or skew, shrinkage of coating and the whole building;

- environmental purity;

- high strength and resistance to mechanical exposure;

- speed and simplicity of installation - to strip the house with a metal block house, you can even do it yourself;

- easy to care for the surface;

- the possibility of masking of minor defects of the walls of the walls;

- the lining of the house with a metal block house will cost inexpensively;

- damage to the material during transportation due to the polymer protective coating is excluded, it means it is almost impossible to overrun the block house.

Important! Outwardly, a house with a metal block house, under the log, looks like a full-fledged log cabin. To identify differences can only qualified specialist in this area. But, it must be borne in mind that such panels are sufficiently heavy, so they are suitable exclusively for external lining of houses with a suitable carrier load.

Parameters block house

The line of this product is presented in the market standardized parameters. Since there are 2 types of metal block house, sizes for each of them will be different:

- Single panels:

- useful width - 188 mm;

- full width - 210 mm;

- length - 0.5-6 meters;

- thickness - 0.5 mm.

- Double panels:

- useful width - 360 mm;

- full width - 390 mm;

- length - 0.5-6 meters;

- thickness - 0.5 mm.

Important! As for the choice of shade, each manufacturer usually represents a full range of colors of the most sought-after breeds of natural wood. The highest popularity today is the following tones:

- antique;

- dark oak;

- golden oak.

Metal Block House

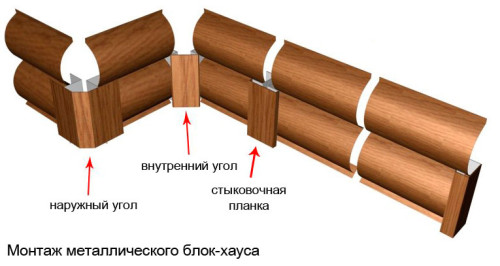

The metal block house is not only externally attractive and has excellent technical properties. It is usually delivered on sale, like siding, in the form of a set with a complete set of all necessary parts for the trim of a particular facade area. This greatly simplifies the installation process itself and reduces the preparatory phase.

The standard set consists of such elements:

Depending on which manufacturer, you order a metal block house for your home, the kit may include additional details.

Installation of metal block house

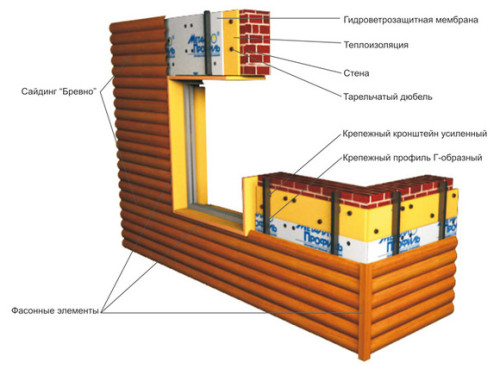

Structurally, the device of such a finish is not much different from other materials. Usually, this is a multi-layered structure that includes:

- clamp;

- insulation;

- vaporizolation;

- decorative material itself.

Important! Blocking at home by a block house must be done only on durable walls. That is, if earlier the house was plastered and the coating is already well holding, you first have to completely remove it, clean the surface. If the building is composed of wood - be sure to treat it with antiseptic solutions and wait for them absorbing them. Only then you can perform installation of a metal block house with your own hands.

Installation technology:

- Choose a suitable installation technology - vertically or horizontally.

- Prepare the required amount of metal profiles or wooden bars 40 * 40 or 50 * 50 mm for the crate.

Important! So that all the boards were the same length and widths, slow down the pre-1 template and on it begone the rest of the number of necessary parts.

- Install the top and bottom rail.

Important! Fastening Perform galvanized screws of suitable length.

- Consistently fill in the shellboards internal space in a step of 40-60 cm.

Important! Focus on the width of the insulation. He must be tightly between the slats. To withstand equal gaps, pull the thread or construction cord and focus on them.

- Install the insulation plates - mineral wool or foam.

- Fix the insulation with umbrella dowels.

- Lay over a vapor barrier film.

- Secure it with brackets from the stapler on the shell boards.

Important! Tensioning the film so that it is close to the previous layer, but not strongly stretched and did not save.

- Install the second series of crates perpendicular to the first.

- Secure the bearing brackets.

- They put M-shaped profiles on them.

- On the profiles consistently mounted all parts from the block house set, snapping them between themselves and fixing themselves with self-draws.

Important! Do not navigate the panels too tight, but do not allow them to break down. As with working with metal products, slate, the mount is made relatively dense, but the gap is required for a possible linear extension. In any case, do not allow slots and holes - the coating should be solid.

Mounting Metal Block House - Video

Conclusion

Metal block house under a log is a wonderful modern alternative to natural wood. The use of such a material will not only help you significantly reduce the estimate for the construction and maintenance of the cottage, but also to move to a reliable and beautiful house in extremely short time.