Paint for collapse: what to use how to breed paints and varnishes

Any finishing work wants to spend as quickly as possible so that the car or room has acquired an attractive appearance, and it could be used for its intended purpose. That is why today everything is less commonly, homemade masters are taken behind the brushes and rollers, and prefer painting from the collapse. Such a technology allows you to get a perfectly smooth and smooth coating in counting minutes, and to spend the minimum of forces. But that the result corresponds to expectations will have to comply with certain rules. For example, it is properly determined which paint is suitable for collapse in your case, and how to make it right. You will learn about this from this article.

Content

Why do you need to properly breed paint?

How to breed paint for collapse, you need to know everyone who wants to use this tool during the finishing work.

To find out all the information and it is necessary to use it for the following reasons:

- Too viscous, thick paint is difficult to evenly distribute on the desired surface with a thin layer. An increase in the thickness of the layer will entail the extension of the dying and overrun of the material.

- When processing vertical or inclined surfaces, ugly leaks are formed too thick or liquid paint, fix that can be only new staining.

- Most of the models of the paintopult, especially inexpensive, will not cope with the feed of thick paint. Internal parts will be scored, and the flow will be either uneven, or the paint will not come from the device at all.

- Too viscous paint, even with thorough preparation of the surface, will not fill fine irregularities, roughness, microcracks. As a result - the coating will not be even, and over time, corrosion can form in flaws of the surface, the dust, garbage can accumulate.

- Too diluted, liquid paint will not give the desired external effect. We will have to paint with a large number of layers, and as a result, the coating will not be so durable as I would like, and you will have to spend much more time on painting.

Important! The paint for the paint should be appropriate quality, regardless of how expensive or cheap tool model you purchased. With this approach, subject to staining technology, you in any case will be able to realize your idea and paint the desired surface.

What paints are suitable for collapse?

The modern market of paints and varnishes offers a wide range of finishing solutions. Many of them can be safely taken to refuel the collapse. Paints of such compositions are perfect for this purpose:

- alkyd;

- acrylic;

- water-emulsion;

- oil;

- nitroemali.

Important! What kind of paint for electric painting to give preference, determine based on what exactly you are going to paint:

- for wooden surfaces, oil or acrylic solutions are best suitable;

- for car - nitroemali or alkyd mixtures;

- Water-emulsion, acrylic and alkyd compositions are often used for wall decorations.

The main selection criteria are the expected result of the strength, stability of adverse effects, durability, attractiveness, and, of course, the cost of the paint itself.

Collectants for paint - Classification

To bring paint to collapse to the desired consistency, it is necessary to choose the right solvent. To do this, if it is thorough to approach the process, determine the liquid you need according to the criteria below.

Important! A simpler and minor option - use special branded solvents recommended by the paint manufacturer. So you will definitely be avoided to avoid errors and do not have to choose the best solvent internally. But, be prepared for the fact that saving time and forces in this case will cause large cash spending.

Component composition

Each type of paint has its own component composition, in which there is a certain amount of solvent and the painting substance itself. According to this principle, the classification of paints is carried out as follows:

- low-filled;

- secondary;

- highly filled.

Important! Paints of the first type are not recommended to breed a large amount of solvent. In some cases, in some cases, you can add up to 30% of the solvent volume. If you encountered only with paint marking, keep in mind that gradation in the direction of reducing the indicator looks like:

- VHS;

- UHS;

- MS;

- HS;

- HD;

- Ls.

Solvent type

Another important factor when choosing a suitable solvent is its polarity. On this criterion, only 2 types of compositions are distinguished:

- non-polar;

- polar.

Important! Since there can be quite a lot of substances to the paint and the solvent itself, then only on its own intuition or one marked in the list it is impossible to accurately determine the polarity of the composition. We take into account the fact that not all manufacturers indicate the packaging the full composition of the mixture, justifying it by a commercial secret. Therefore, in this case, the choice of combination of paint and solvent is appropriately practically or expensive method of laboratory studies. But, for the last option, it is unlikely that someone agree to go, performing work exclusively to a one-time nature for your own needs. An easier option is to trust the recommendations of those who have already tried various options and picked up the desired solvent. With them you will read below in this article.

Temperature conditions when painting

When diluting paint for collapral, it is necessary to take into account in what temperature conditions you will work and how soon after the preparation of the solution, proceed to staining.

Important! In order to find out the exact viscosity data and the rapid speed of paint, you can use a special device - a viscometer.

About how to use it correctly, find out from the video instructions below.

Regarding this rule, the recommendation of specialists look like this:

- Quick solvents Select if staining will occur at temperatures below 18C.

- Normal - if the temperature indicator of 20-25 degrees is stable.

- Slow - if indoors or on the street is very hot and the temperature exceeds 25c.

Important! Take into account the additional nuances that relate to color paint. Brilliant "metallic" or "pearl" better breed slow solvents. Then you will be able to avoid the effect of cloudiness and non-uniformity of the layers.

Useful recommendations for the choice of solvent

If you doubt your choice, use one of the following solvents under a specific paint type:

- Acrylic - special solvents, R-12 or P-651.

- Alkyd - P-4, xylene, toluene.

- Nitroemal is a special solvent recommended by the paint manufacturer or P-646.

- Water-emulsion - suitable for breeding normal distilled water, alcohol, ether.

- Oil - Olife, oil varnish.

Important! The standard dilution rate ranges from 5 to 25%. As for the consumption of paint itself, these data are indicated on the packaging by the manufacturer. If the paint is properly applied, these values \u200b\u200bcan slightly decrease.

Application of kraskopulture

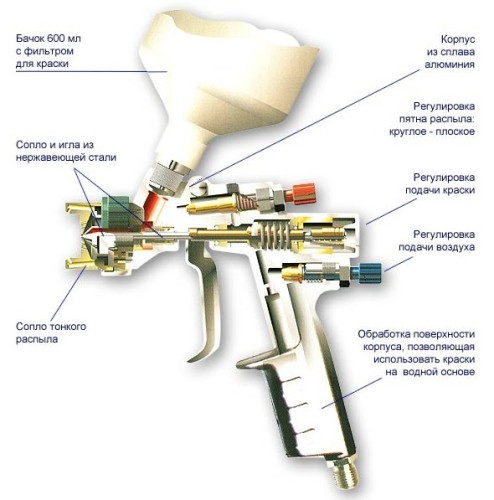

Painting with a spray irmentation or any other paint is not a complex process. Detailed instruction manual and tuning the tool itself is usually attached to the passport for equipment.

Important! Carefully explore it before starting to perform work. Try to pre-refuel the tool so that you thoroughly understood how it functions.

In the course of the staining procedure, be sure to consider the following rules that will help you avoid technological errors and interpretation of the mixture:

- Qualitatively prepare the stainable surface - close the cracks and holes, remove the construction trash, traces of rust and dust, lie down the base.

- Wipe the surface with suitable composition:

- when using acrylic or latex paint - water with soap;

- when applied with oil - White spirit.

- Wipe with a clean cloth moistened with water, wait for the surface drying.

- Protect the adjacent surfaces with the film, and the respirator, gloves and overalls.

- When staining the ceiling, gradually move from one site to another. If there are many paints to apply for one spacing of the surface, the solution will drip down or freeze in the form of ilk.

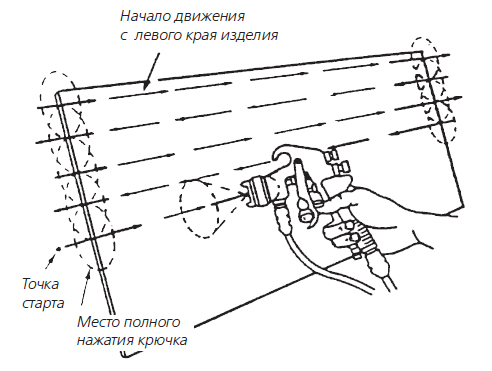

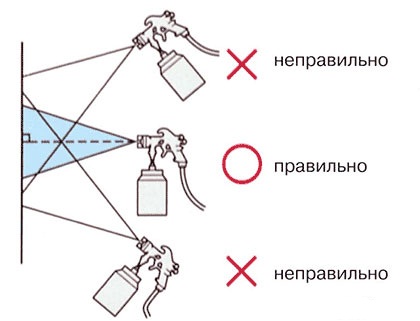

- The jet direction strictly perpendicular to the surface, circular motions.

- Before applying the next layer, make sure that the previous one is dry. According to standards, the technical pause should be at least 6-12 hours (the time depends on the composition of the paint).

Important! About how to properly paint electric paint, browse in this video.

Conclusion

Now you know which paint can be used for collapse and how to do it. If you are still in doubt whether it is worth using such a tool, read the technical data of different models of spray guns, with pluses and cons of their use. Be sure to consider the level of your own knowledge and skills, it is possible that painting the paintopult is the only true option for you, if you want to finish working with high quality and do it yourself.