Installation of a bath furnace with your own hands. detailed instructions Baths, saunas and pools

The bath is a place where a person rests with a soul body. Hot bath couple cleans and rejuvenates the body, gives youth and feeling lightness. And to feel all the beneficial properties of the bath, you need to choose and install the oven.

Content

Varieties of bath stoves

Bath furnaces are divided into manufacturing material and the method of sipping:

- brick (oven heater) oven,

- metal,

- electric furnaces.

By way of location of stones:

- with an open heater (stones are heated to a temperature of 200-250 degrees),

- with a closed heater (the heating temperature of 400-500 degrees).

By the method of heating stones:

- furnaces of periodic action - they heat up faster and also cooled,

- furnaces of continuous action - on the contrary, heat-resistant and heat-resistant,

- a separate view is a wood-burning furnace, they differ in the method of finishing and sizes.

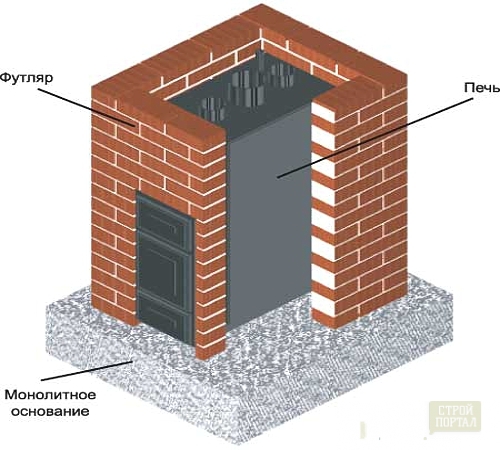

Installing a brick bath furnace with your own hands

The main principle when installing any kind of furnace is fireproof. For the construction of a brick furnace will need:

- refractory brick,

- brick laying solution

- asbestos cardboard

- consumables building materials (roulette, spatula, sandpaper).

So, how to build a bath oven from a brick?

- Any construction begins with the sketch of the plan scheme. It indicates the dimensions of the planned construction, in this case, the bath oven, and the end result is sketched, as it should look after the construction is completed.

- The next step is poured the foundation. For a bath furnace, he must be separate from the main foundation of the entire bath. Therefore, in a bathroom in the place where the furnace installation is planned, the foundation is not filled. At the left, a pit is digging about 1 meter deep and falling asleep with sand half, then with a brick, stone, not reaching the edge of the pit of centimeters ten. The rest is falling asleep by rubble. The formwork is constructed and concrete flooded. Such preparation is necessary in order to be under the foundation for the land, and the oven remained hot.

- After 7 days, the finished foundation is filled with tar (resin), and on top covered with rubberoid. This is waterproofing.

- Next, we build the furnace itself. A solution is prepared - concrete glue for refractory bricks. The first layer of brick is laid out on a layer of waterproofing. Approximately on the third row of the masonry is installed a confusion door. Another brick layer is laid and a cast iron grille is installed. Over the grille, another seven rows of bricks are stacked and the door for the furnace is mounted. In the side wall of the furnace in the same stage the pipe is inserted. The exhaust pipe can be fixed on the back wall. But this location requires additional fastenings with metal clamps. Then metal chawliers are put on the side walls of the furnace and the well is being placed on them. Another 5 rows of bricks are stacked and another lattice is mounted on them - it is a grace on which stones will lie.

- If the construction of an open-type furnace is assumed, two rows of bricks are stacked above the grate, and the pipe through the ceiling is removed on the street. If this is a closed type - bricks are laid out above the gradation, gradually narrowing to the top. There is also mounted a small steam door. And at the end remains a hole for the exhaust pipe, if it passes along the back wall of the oven.

- It remains to walk the emery material on the external walls of the furnace. If desired, the furnace can be chopped by ceramic tiles.

The attachment of such a furnace occurs either to firewood - they fit into the furnace to the furnace on the grille. Either the gas burner is supplied to it and is set up. Before each pointing, the bath must necessarily add water into the boiler through the grate. It is this tank that gives a wet steam in the bath. And rinse stones from excessantly scale, perhaps from a small sediment of soot. The temperature in the bath with a wet ferry should not exceed 90 degrees.

Installation of metal furnaces

You can also make a metal bath furnace. The principle of the location of the necessary furnace elements is the same as in the brick. Only walls are welded from metal, as a rule, steel.

Another, simpler, option is to buy a finished furnace and make an installation yourself. A finished metal bath furnace is usually an open type, installed strictly on the applied instructions from the manufacturer. The main thing is to establish this furnace on a refractory surface, for example, asbestos cardboard, and fasten well. The hole in the ceiling or wall for the output of the pipe to the street is also important to protect asbestos ring.

When choosing metal finished furnaces, it is important to pay attention to such a characteristic as power. It corresponds to the area that the unit can heat up to the required temperature. If the furnace is insufficient power, it is impossible to heat the bath, too powerful models warm the room faster, but it will be excessive heat to have a destructive nature and lead to premature destruction of the foundation and the bath itself.

Installation of electric furnaces

Bath electric furnaces are installed mainly in the sauna. This is a bath, for lovers steaming dry steam. Since the electric oven does not allow watering (serve) with water with water. When installing the electric furnace, the room-steam room can be attacked by + 100-120 degrees.

When installing such a stove, it is important to connect power properly. The procedure is reduced to high-quality thermal insulation of electrocabels. The insulating material must withstand temperatures up to 100 (better 150) degrees Celsius. Otherwise, the risk of melting winding occurs. Even in a dry room, without a wet couple, it will lead to a short circuit. Given that the baths are usually made from the tree, the electric arc in the place of isolating is able to cause fire.

Otherwise, the electric furnace is also set as metallic.

Firms manufacturers of high-quality bath stoves

To date, there are many firms manufacturers of bath furnaces. Specialists competently select the oven on the square of the bath, based on the conditions in which it is built (gasification, electricity, water supply, etc.). Here are some of them who have proven themselves in this market in Russia:

- The company "Varvara" - the production of wood bathing stoves and components. A number of rational and small furnaces are presented for those people who have no opportunity to carry out appropriate communications to the bath.

- Trading house "Techno raid" - the production of all types of furnaces. A big plus - the construction of furnaces for individual orders. The central office in the city of Novosibirsk. They have offices in many Russian cities.

- The manufacturer of stone ovens for baths and saunas "triple furnaces". Sells ready-made ovens. Do not make the furnace according to individual parameters. (Tver, offices in Moscow).

- "Teplostal" - a manufacturing company, the Kirov. Delivery sauna stoves of all modifications to any city in Russia. Advice is available on toll-free hotline. Only minus is that expensive shipping out in distant cities.

Large popular baths are in Europe. And here are a few companies producing sauna stoves abroad:

- «Harvia» (Finland) - manufacturer of electric furnaces for saunas. A wide range of low cost and the possibility of delivery in Russia, output this company in a leading position.

- «HELLO» (Sweden) - manufacturer of components for all types of baths (Russian bath, sauna, Turkish bath). Eksportirtiruet their products to any country.

new comments

Add a comment

To post a comment you need to authorize.

If you do not mind, I just pokritikuyu.Sam I am installer furnaces and kaminov.Vo First it is important to pay attention to safety, very much nyuansov.Vo second entrust this job better way spetsialistam.I-asbestos sheets found vrednymi.Est new materials. thanks